Heat supply system of gas boiler room and energy utilization method

A technology for heating systems and boiler rooms, applied in heating systems, heating methods, household heating, etc., can solve the problems of insufficient resource conservation and civilization, transmission efficiency, environmental pollution that cannot meet energy demand, and energy utilization in gas-fired boiler rooms Single and extensive methods, etc., to achieve the effect of improving comprehensive energy utilization efficiency, increasing annual utilization rate, and saving gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

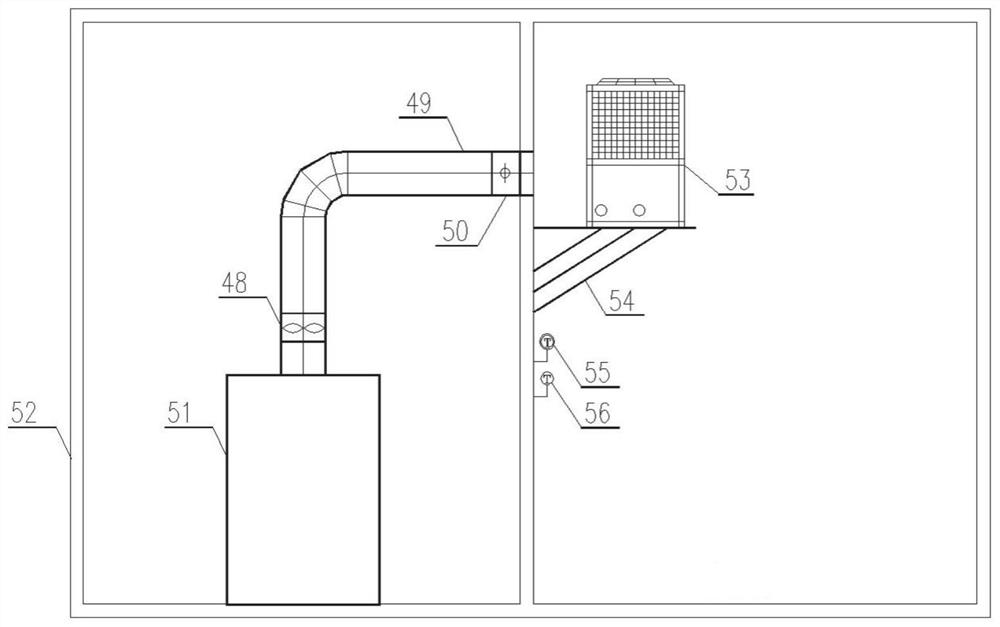

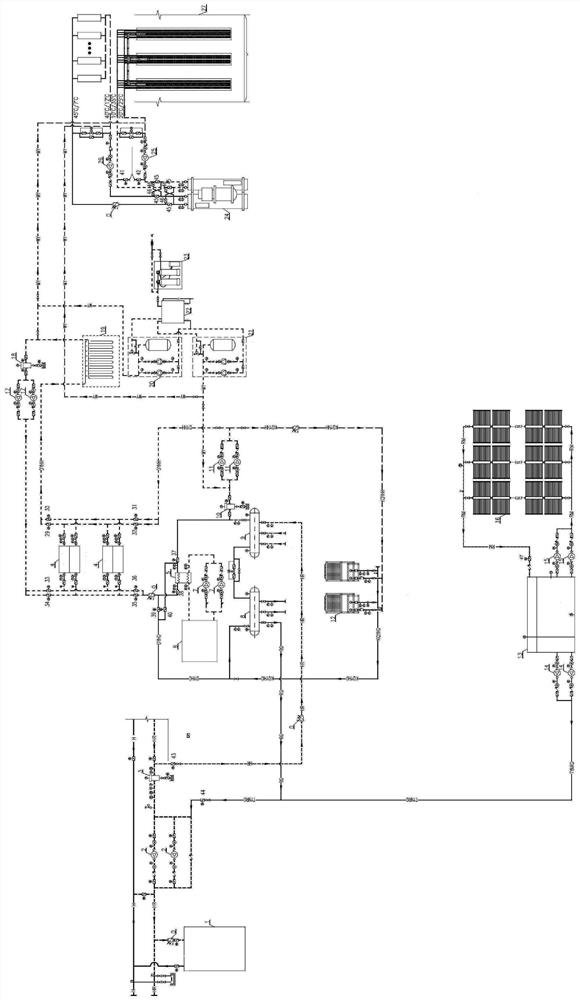

[0047] Such as Figure 1-2 As shown, the present invention discloses a heating system for a gas-fired boiler room. The system is a heating system that realizes "multi-energy complementarity" for a gas-fired boiler room. The connection of water tank and water collector; the connection of air source heat pump system, ground source heat pump system and cross-season energy storage water ring system are connected in parallel.

[0048] The boiler hot water system includes a boiler, the water outlet of the boiler is connected to the water supply pipeline; the water inlet of the boiler is connected to the return water pipeline. A heating system circulating water pump 2 and a heating system decontamination device 3 are arranged on the return water pipeline. The return water pipeline is respectively connected with the solar hot water supply pipe and the heating return water pipe. The design temperature of the gas boiler 1 hot water system is 40 / 110°C, and the quantity-quality adjustme...

Embodiment 2

[0061] In the second aspect, the present disclosure also relates to an energy utilization method, based on a heating system of a gas boiler room 1 of the present disclosure, specifically as follows:

[0062] During central heating in winter, when the outlet temperature of the solar collector 16 reaches the set temperature of 60°C, the seventeenth electric valve 47 is opened and the solar hot water heat storage circulating water pump 15 is chained to start the high temperature water pressure in the solar collector 16. into the solar hot water storage tank 13; when the outlet temperature of the solar collector 16 reaches the set temperature of 45°C, the solar hot water heat storage circulating water pump 15 is closed, and the seventeenth electric valve 47 is closed; the above process is repeated, The water level in the solar hot water storage tank 13 gradually rises, and when the water level in the hot water storage tank reaches 100%, the seventeenth electric valve 47 and the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com