Integrated control method and system for wet desulphurization absorption tower system

A desulfurization system and wet desulfurization technology, applied in chemical instruments and methods, separation methods, non-electric variable control, etc., can solve the problems of limestone waste, small pH value amplitude, and large pH value change amplitude, etc., to reduce The effect of controlling difficulty and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

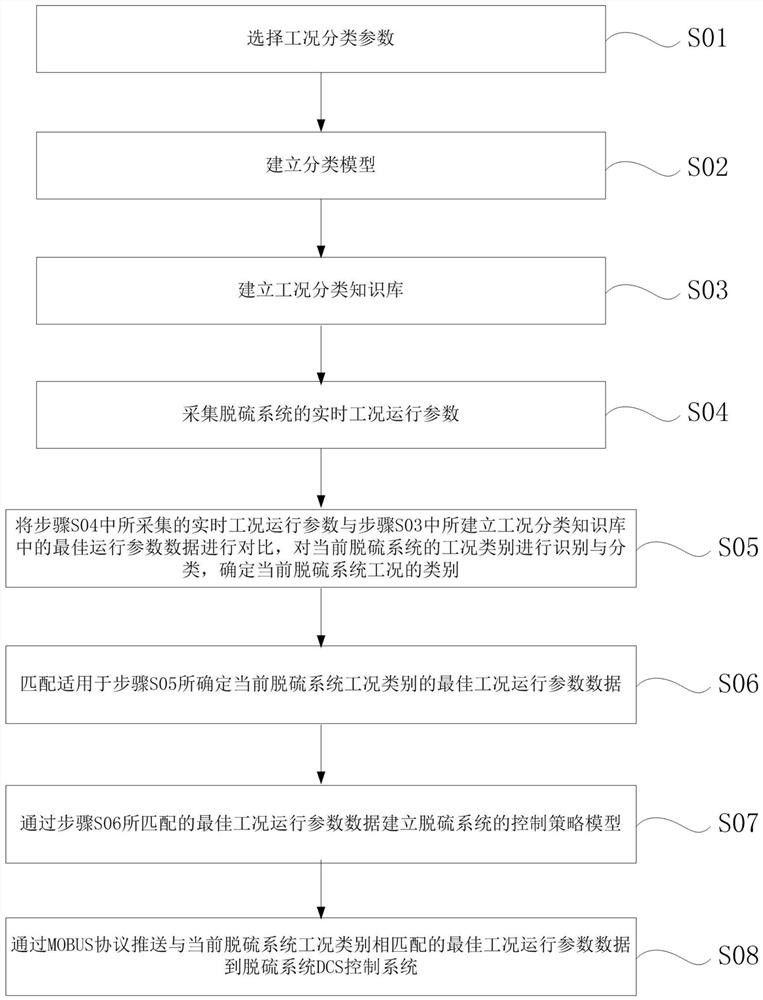

[0031] Embodiment 1 of the present invention: an integrated control method for a wet desulfurization absorption tower system, including the following steps: Step S01: Select working condition classification parameters: determined by mechanism method, Pearson linear correlation algorithm, and PCA principal component analysis method Unit load, main steam flow, total coal supply, total air volume, raw flue gas sulfur concentration, raw flue gas temperature, net flue gas sulfur concentration, absorption tower PH value, slurry circulation A pump current, slurry circulation B pump current , slurry circulation C pump current, slurry circulation D pump current, slurry circulation E pump current, absorption tower system resistance, absorption tower liquid level, net flue gas oxygen content and slurry replenishment flow, these 17 variables are used as the characteristic variables of the model; step S02 : Establish a classification model: classify the working conditions through the K-mean...

Embodiment 2

[0032] Embodiment 2 of the present invention: an integrated control method for wet desulfurization absorption tower system, including the following steps: Step S01: Select working condition classification parameters: determined by mechanism method, Pearson linear correlation algorithm, and PCA principal component analysis method Unit load, main steam flow, total coal supply, total air volume, raw flue gas sulfur concentration, raw flue gas temperature, net flue gas sulfur concentration, absorption tower PH value, slurry circulation A pump current, slurry circulation B pump current , slurry circulation C pump current, slurry circulation D pump current, slurry circulation E pump current, absorption tower system resistance, absorption tower liquid level, net flue gas oxygen content and slurry replenishment flow, these 17 variables are used as the characteristic variables of the model; step S02 : Establish a classification model: classify the working conditions through the K-means ...

Embodiment 3

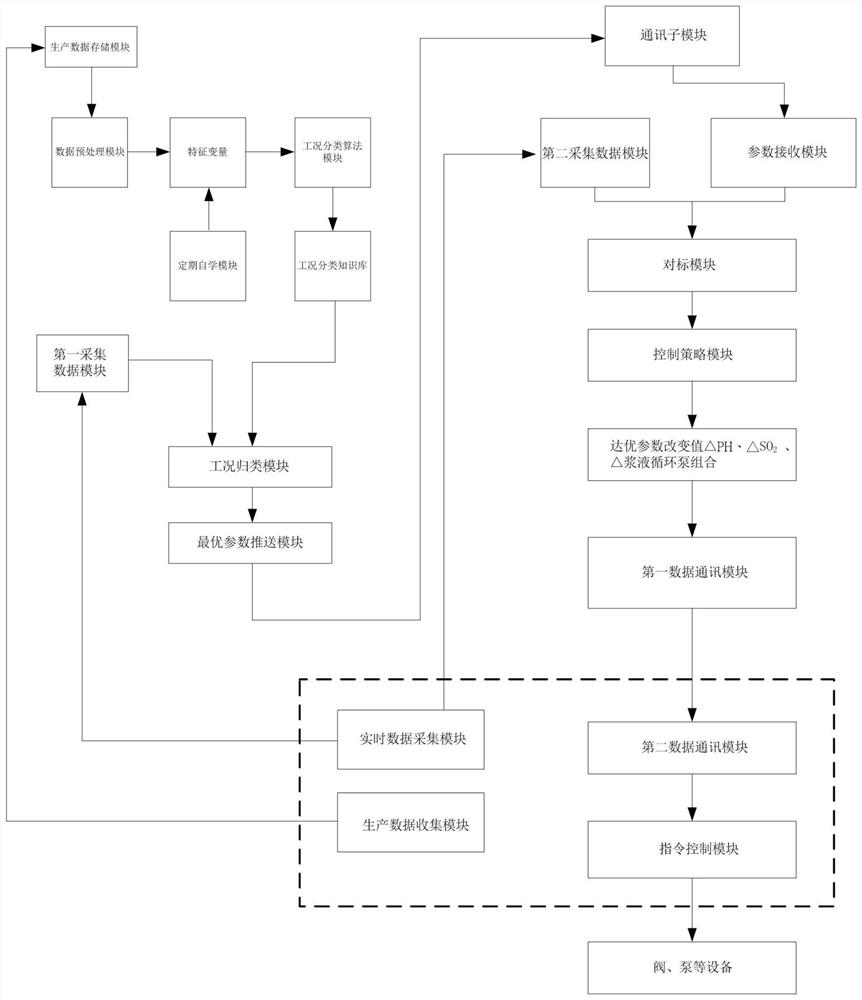

[0034] Embodiment 3 of the present invention: an integrated control system for the wet desulfurization absorption tower system, including a production data storage module, which is connected to the data preprocessing module, and the production data storage module is used to store the data collected by the production data collection module Historical production data of the desulfurization system;

[0035] The data preprocessing module is used to select the characteristic variables, and the data preprocessing module uses the mechanism method, the Pearson linear correlation algorithm, and the PCA principal component analysis method to determine the characteristic variables, such as unit load, inlet sulfur content, flue gas temperature outlet sulfur content , PH value, slurry circulation pump current, etc.;

[0036] The operating condition classification algorithm module is used to classify the operating conditions of the desulfurization system through the classification algorithm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com