Kapok felt and carbon cloth composite non-woven felt, and needling reinforcing method and application thereof

A non-woven and kapok felt technology, which is applied in the field of non-woven fabric preparation, can solve problems such as interface deposition, decrease in overall strength, and affect evaporation effects, and achieve stable heat production, stable heat maintenance, and high-efficiency heat absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a needle-punched reinforcement method for kapok felt and carbon cloth composite non-woven felt, which mainly includes the following steps:

[0034] 1. Material preparation: choose a gram weight of 100g / m 2 kapok felt, choose 250g / m 2 carbon cloth;

[0035] 2. Laying the net: use the above-mentioned kapok felt with a certain thickness as the base cloth, and spread the corresponding carbon cloth on the kapok felt;

[0036] 3. Reinforcement: Acupuncture the composite laminated kapok felt and carbon cloth; the needles pass through the carbon cloth and the kapok felt in turn from the side of the carbon cloth. The needling depth is 6 mm, and the needling density is 200 pricks cm -2 .

Embodiment 2

[0038] This embodiment also provides a needle-punched reinforcement method for kapok felt and carbon cloth composite non-woven felt, which mainly includes the following steps:

[0039] 1. Material preparation: choose a gram weight of 100g / cm 2 kapok felt, choose 250g / cm 2 carbon cloth;

[0040] 2. Gluing: Epoxy resin adhesive is applied on the contact surface side of kapok felt and carbon cloth, and the amount of glue applied is 10g / m 2 ;

[0041] 3. Pressure application: paste a layer of kapok felt and carbon cloth together, press the kapok felt and carbon cloth under the condition of unit pressure 1.2MPa, the pressing time is 2h, and release the pressure directly after pressing.

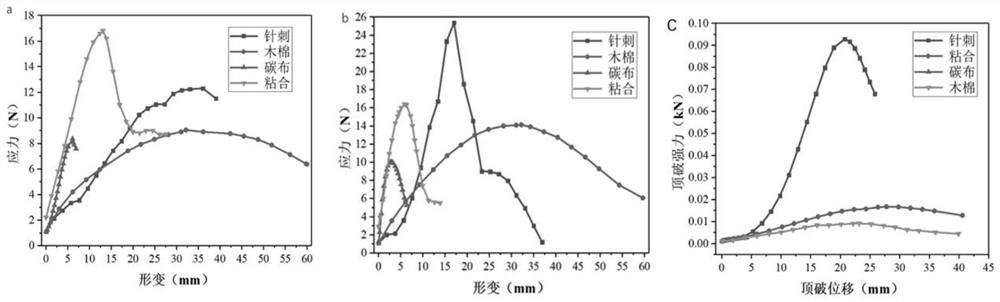

[0042] Obtain the tensile (horizontal, longitudinal) of finished product in embodiment 1, embodiment 2 and burst mechanics test data such as figure 2 Shown, the water evaporation rate (light intensity is 1kW.m -2 ) under the conditions of the test results are shown in Table 1:

[0043] Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com