Zinc chloride solution multi-effect evaporation and concentration production process

A technology of zinc chloride solution and production process, applied in the direction of multi-effect evaporation, zinc halide, etc., can solve the problems that the steam cannot be used again, the steam is easy to diffuse, and the consumption is large, so as to achieve short start-up time, short residence time, The effect of short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Example 1: A kind of zinc chloride solution multi-effect evaporation concentration treatment process

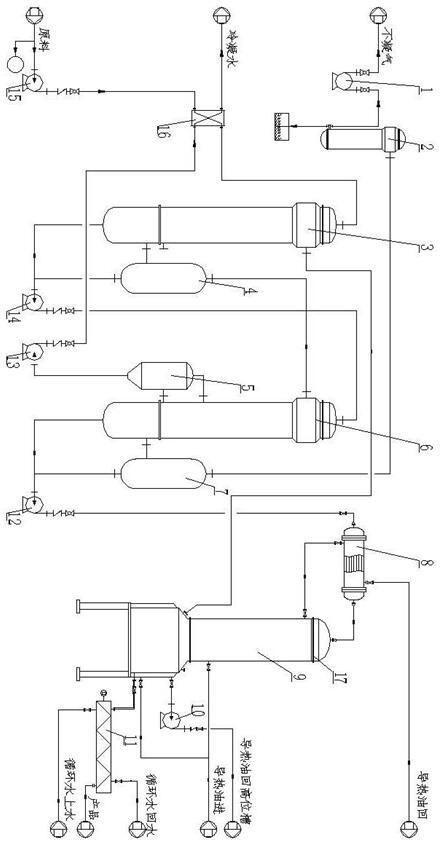

[0031] Such as figure 1 Shown, zinc chloride solution multi-effect evaporation concentration treatment process comprises the following steps:

[0032] (1) During normal operation, the feed liquid with an initial mass concentration of 40% enters the plate heat exchanger 16 through the feed pump 15 for preheating, then is fed from the upper end of the first-effect falling film heating chamber 3, and is evenly distributed to each In the heat exchange tube, it flows down in a uniform film along the inner wall of the heat exchange tube. The liquid film is heated by shell-side steam during the flow process in the tube side of the heating chamber, and the generated steam and part of the liquid phase enter the first-effect separation chamber 4 to complete the vapor-liquid separation, and the secondary steam enters the second-effect falling film heating chamber 6 as a heating ...

Embodiment 2

[0037] Example 2: A zinc chloride solution multi-effect evaporation concentration treatment process

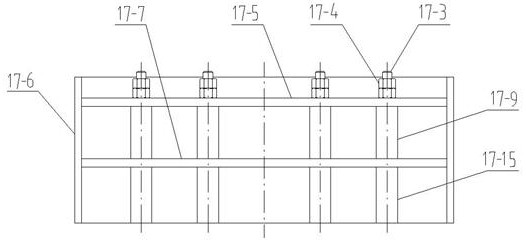

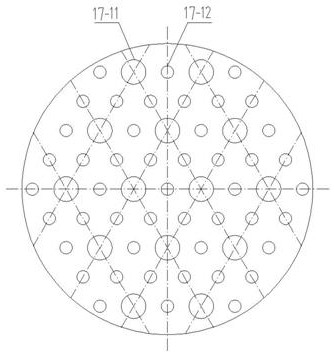

[0038] On the basis of Example 1, such as Figure 2-5 As shown, the upper part of the high-temperature concentration chamber 9 is provided with a material distributor 17, and the distributor 17 includes an upper distribution plate 17-5, a lower distribution plate 17-7, a distance pipe A 17-9, a distance pipe B 17-15, a poly The liquid cylinder 17-6 and the tube sheet 17-8, the upper distribution plate 17-5 is arranged on the top of the liquid collecting cylinder 17-6, the lower distribution plate 17-7 is arranged inside the liquid collecting cylinder 17-6, and the upper layer distributes The disk 17-5 is parallel to the lower distribution disk 17-7, and the distance pipe A 17-9 is arranged between the upper distribution disk 17-5 and the lower distribution disk 17-7, and the lower distribution disk 17-7 and the tube plate 17-8 There is a fixed distance tube B 17-15 between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com