Low-resistance ship

A low-resistance, ship-based technology, applied in the field of ships, can solve the problems of multi-energy, energy waste, consumption, etc., and achieve the effects of reducing pollution, reducing wave-making resistance, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Detailed description will be described in connection with the schematic illustration below. The advantages and features of the present invention will be more apparent from the following description. It is to be noted that the figures are in a very simplified form and are used in the use of non-precision ratios, which is for convenience only, and clarify the object of the embodiment of the present invention.

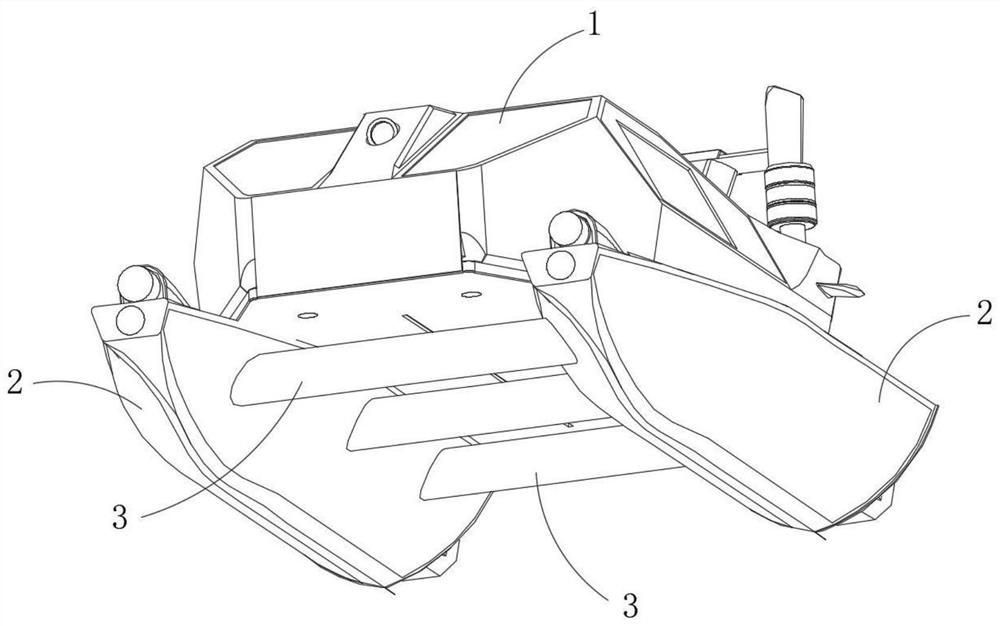

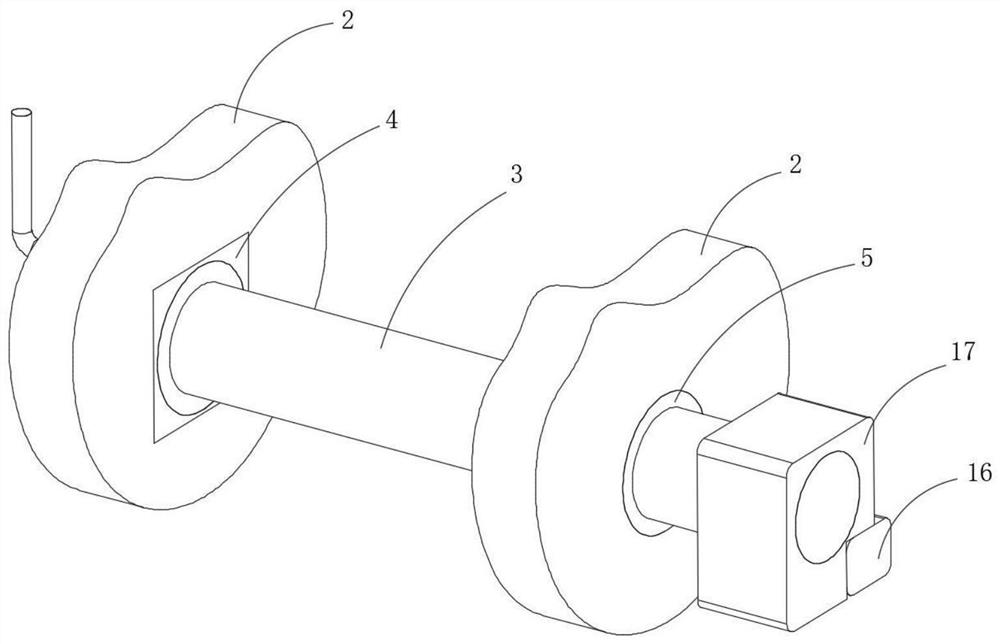

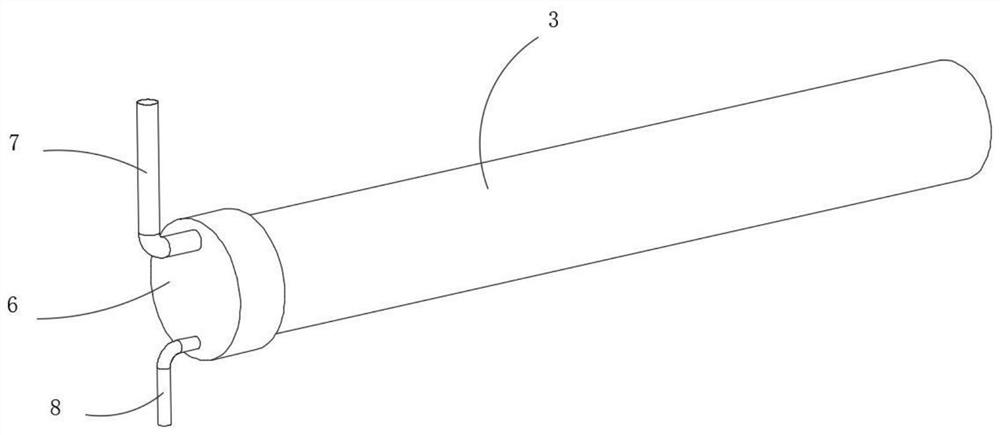

[0026] like Figure 1 - Figure 6 As shown, a low resistance vessel provided in this embodiment, including a hull 1, and a hull 1 is provided with two separate single hull 2, and a lift mechanism is also provided between the two single hull 2. The lift mechanism includes a plurality of lift assemblies arranged axially along the hull 1, and the lift assembly includes a cylindrical lift body 3 and a drive device for driving the lift body 3. The lift body 3 is rotatably mounted on two single hull 2, and the drive device is mounted in a single hull 2.

[0027] When the lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com