Phase change gel for sunlight photo-thermal conversion, and preparation method thereof

A light-to-heat conversion and solar light technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as difficulty in utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

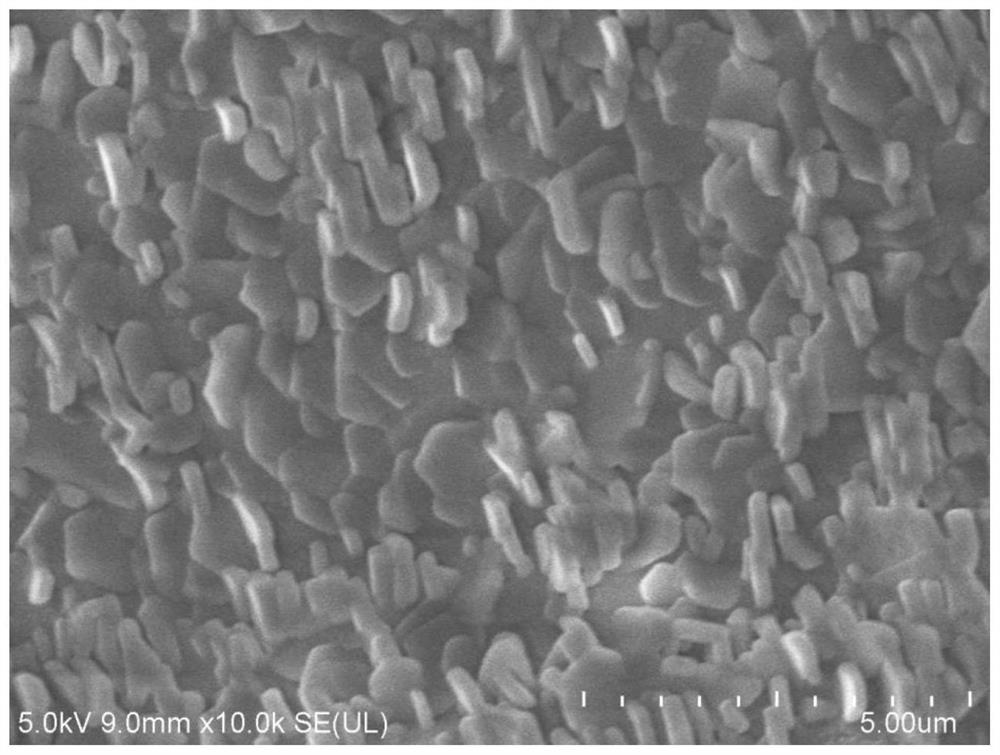

[0046] (1) Carry out chemical surface modification to MWCNT, first carry out acidification treatment to MWCNT, introduce hydroxyl and carboxyl functional group on MWCNT, modification method is as follows:

[0047] 10g MWCNT was placed in 40mL of mixed acid of concentrated nitric acid and concentrated sulfuric acid, the volume ratio of concentrated nitric acid and concentrated sulfuric acid was 1:3, and ultrasonicated at 50°C for 6h to obtain 10.11g MCNT-COOH.

[0048] (2) Take 87g of 1-stearyl alcohol, add it into 50mL of tetrahydrofuran, stir until it is completely dissolved, then add 13g of block copolymer-SEBS to it to completely dissolve in the solution, and obtain a phase change solution.

[0049] (3) After adding 10.11 g of surface-modified MWCNTs into the above-mentioned phase change solution, ultrasonic vibration was performed for 5 min, so that the MWCNTs could be more uniformly dispersed in the solution.

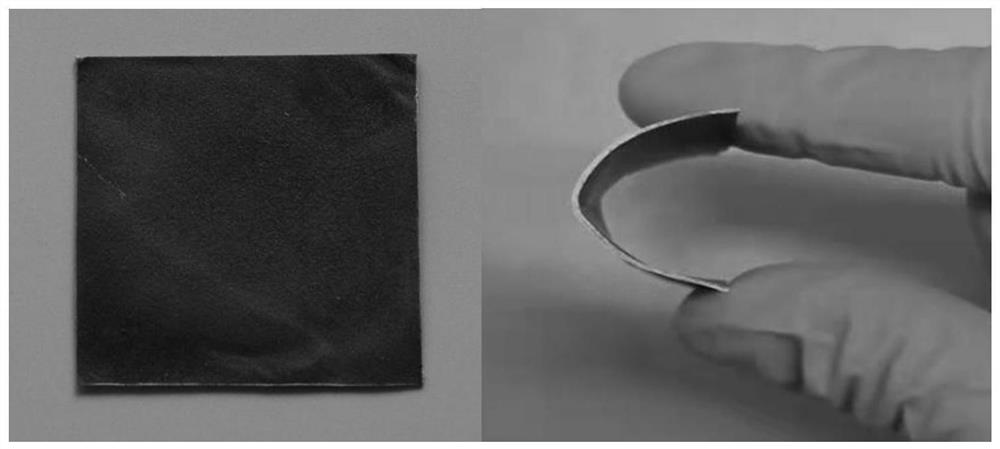

[0050] (4) Get the above solution and transfer it to an open ...

Embodiment 2

[0057] (1) Carry out chemical surface modification to MWCNT, first carry out acidification treatment to MWCNT, introduce hydroxyl and carboxyl functional group on MWCNT, modification method is as follows:

[0058] 5g MWCNT was placed in 40mL of mixed acid of concentrated nitric acid and concentrated sulfuric acid, the volume ratio of concentrated nitric acid and concentrated sulfuric acid was 1:3, and ultrasonicated at 50°C for 6h to obtain 5.3g MCNT-COOH.

[0059] (2) Weigh 87g of n-eicosane, add it into 50mL of tetrahydrofuran, stir until it is completely dissolved, then add 13g of block copolymer-SEBS to it and completely dissolve in the solution to obtain a phase change solution.

[0060] (3) After adding 5.3 g of surface-modified MWCNTs into the above-mentioned phase change solution, oscillate ultrasonically for 5 min, so that the graphene oxide can be more uniformly dispersed in the solution.

[0061] (4) Get the above solution and transfer it to an open beaker. In a fum...

Embodiment 3

[0068] (1) Carry out chemical surface modification to MWCNT, first carry out acidification treatment to MWCNT, introduce hydroxyl and carboxyl functional group on MWCNT, modification method is as follows:

[0069] 1g MWCNT was placed in 40mL of mixed acid of concentrated nitric acid and concentrated sulfuric acid, the volume ratio of concentrated nitric acid and concentrated sulfuric acid was 1:3, and ultrasonicated at 50°C for 6h to obtain 1.1g MCNT-COOH.

[0070] (2) Take 80 g of 1-tetradecyl alcohol, add it into 50 mL of tetrahydrofuran, stir until it is completely dissolved, and then add 20 g of block copolymer-SEBS to it to completely dissolve in the solution to obtain a phase change solution.

[0071] (3) After adding 1.1 g of surface-modified MWCNTs into the above-mentioned phase change solution, oscillate ultrasonically for 5 min, so that the MWCNTs can be more uniformly dispersed in the solution.

[0072] (4) Get the above solution and transfer it to an open beaker. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com