Flexographic printing plate developing solution composition, developing solution, and method of manufacturing original printing plate

A technology for printing original plates and flexographic printing, which is used in printing, photosensitive materials for opto-mechanical equipment, photography, etc. It can solve the problem of reducing developability, developing solution for photosensitive flexographic printing original plates, and poor layout quality. problems, to achieve the effect of improving productivity, shortening plate-making time, and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

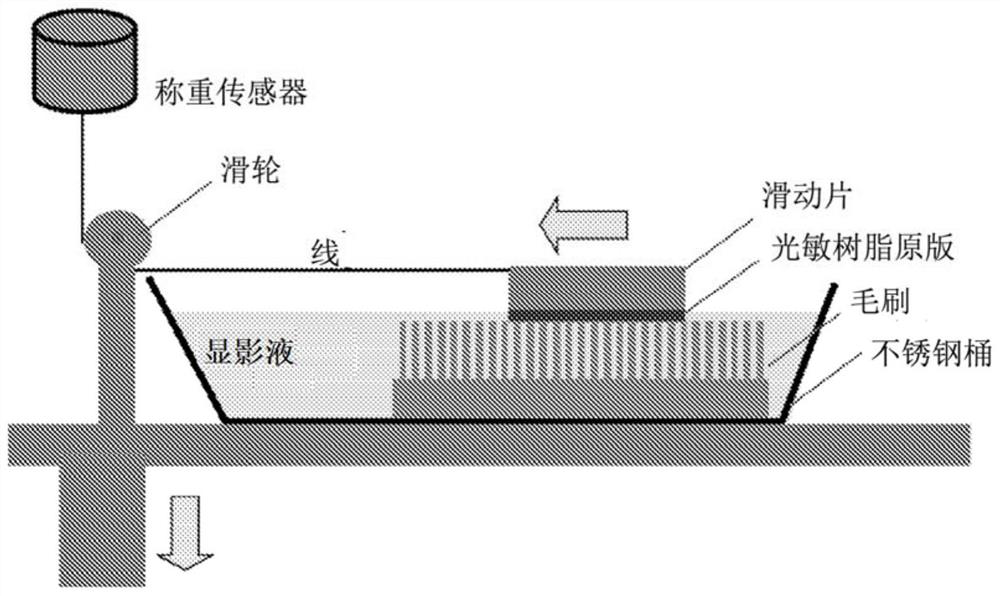

Method used

Image

Examples

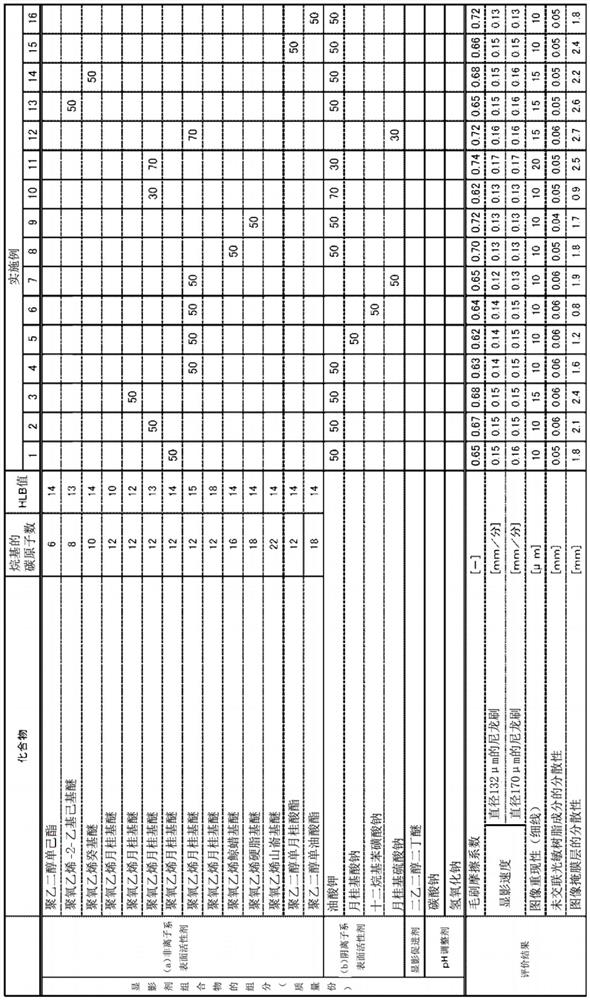

Embodiment 1~16、 comparative example 1~10

[0084]

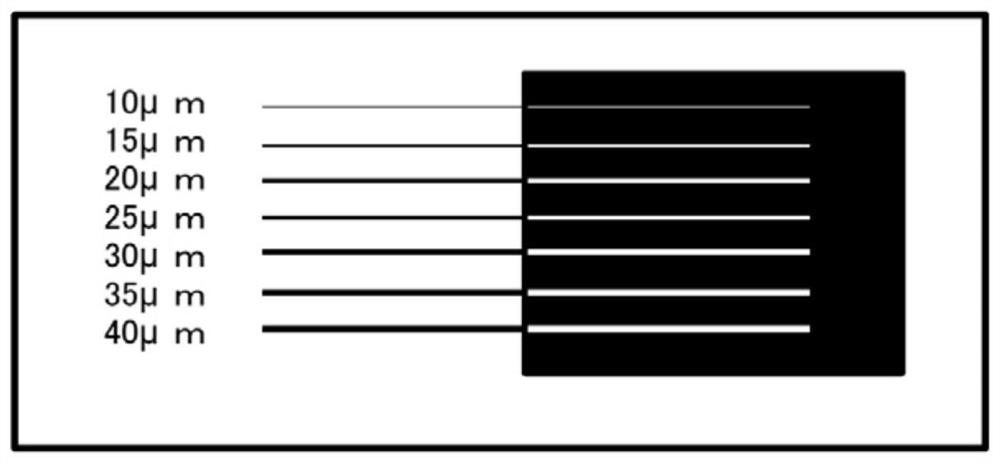

[0085] The developer compositions of the components shown in Table 1 were weighed so that the total amount thereof was 1% by mass of the developer, and each developer composition was dissolved in tap water to prepare examples 1-16 and comparative examples 1-10. Aqueous developer. Specifically, the developer composition was mixed and dissolved while being gradually added in small amounts to tap water in a container while stirring.

[0086] The details of each compound shown in Table 1 are as follows.

[0087] (a) Non-ionic surfactants

[0088] Polyethylene glycol monohexyl ester (BLAUNON PEG200 (manufactured by Aoki Yu Yu Co., Ltd.) 50g and hexanoyl chloride (manufactured by Tokyo Chemical Industry Co., Ltd.) 33.5g were subjected to an esterification reaction in 1L of THF for 1 hour, and THF was evaporated using liquid. In addition, polyethylene glycol (n = 5) monohexyl (6 carbon atoms) ester)

[0089] Polyoxyethylene-2-ethylhexyl ether (BLAUNON EH-6 (manufactur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com