Nutrient substance grinding equipment and use method

A nutrient substance and equipment technology, applied in the field of nutrient substance grinding equipment, can solve problems such as shaft jamming, sticking inner wall, brown sugar raw material is not easy to break, etc., so as to achieve the effect of not easy to clean, improve product quality, and reduce impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

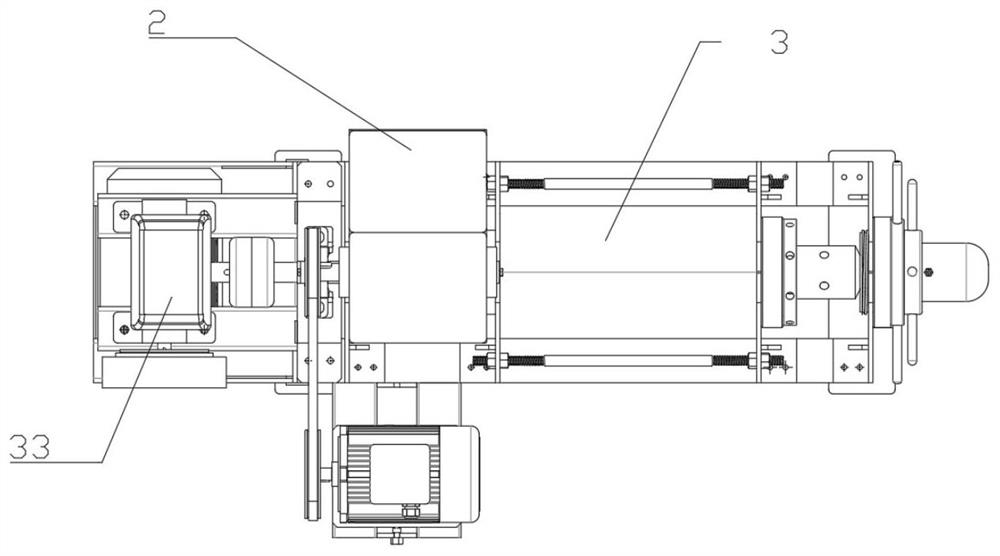

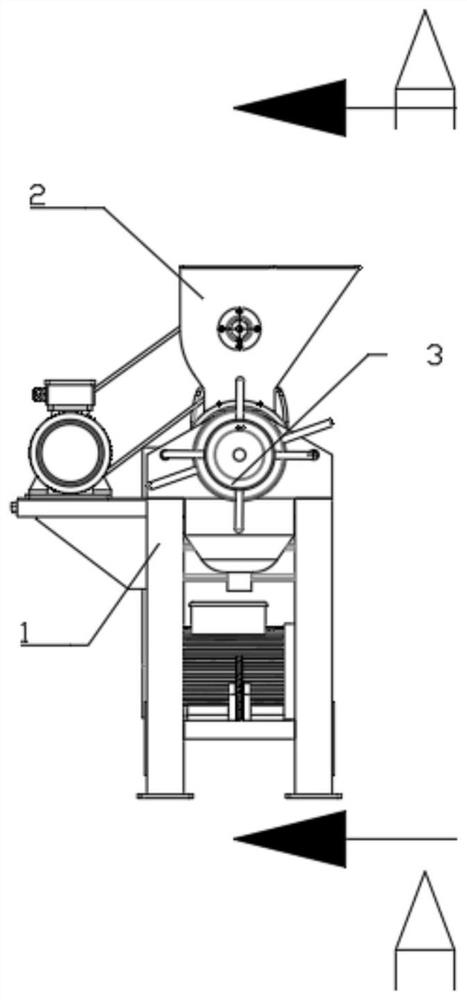

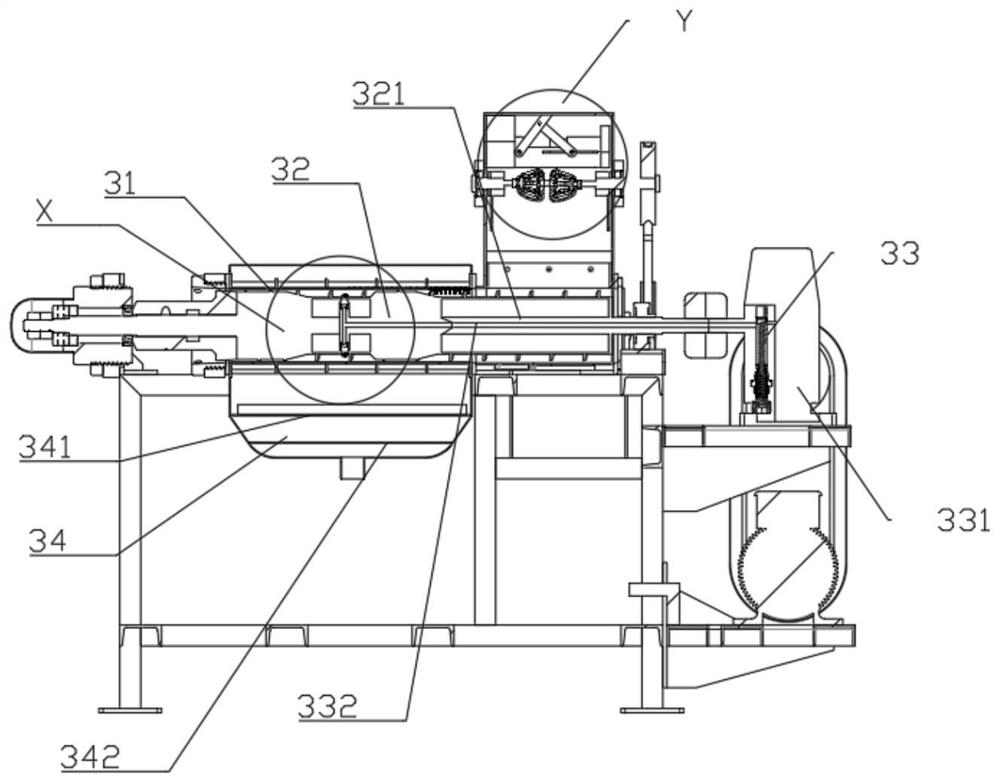

[0061] like Figure 1-7 As shown, a nutrient grinding equipment includes a chassis 1, a crushing mechanism 2, an extruding mechanism 4 and an adsorption mechanism 5. The crushing mechanism 2 is installed on the upper part of the chassis 1, and the extruding mechanism 4 is installed on the upper part of the crushing mechanism 2. The adsorption mechanism 5 is installed in the lower part of the crushing mechanism 2, and the crushing mechanism 2 is stabilized by the bottom frame 1, and then the nutrient material raw materials are poured into the crushing mechanism 2, and the extrusion mechanism 4 located above the crushing mechanism 2 first crushes the nutrient material raw materials. Squeeze to squeeze out the moisture in the nutrient raw materials, then crush the nutrient raw materials through the crushing mechanism, and when the crushed nutrient raw materials fall, they will pass through the adsorption mechanism 5 to remove iron impurities in the nutrient raw materials, etc. Th...

Embodiment 2

[0064] This embodiment is a further improvement of the previous embodiment, such as Figure 1-7 As shown, a nutrient grinding equipment includes a chassis 1, a crushing mechanism 2, an extruding mechanism 4 and an adsorption mechanism 5. The crushing mechanism 2 is installed on the upper part of the chassis 1, and the extruding mechanism 4 is installed on the upper part of the crushing mechanism 2. The adsorption mechanism 5 is installed in the lower part of the crushing mechanism 2, and the crushing mechanism 2 is stabilized by the bottom frame 1, and then the nutrient material raw materials are poured into the crushing mechanism 2, and the extrusion mechanism 4 located above the crushing mechanism 2 first crushes the nutrient material raw materials. Squeeze to squeeze out the moisture in the nutrient raw materials, then crush the nutrient raw materials through the crushing mechanism, and when the crushed nutrient raw materials fall, they will pass through the adsorption mecha...

Embodiment 3

[0070] This embodiment is a further improvement of the previous embodiment, such as Figure 1-7 As shown, a nutrient grinding equipment includes a chassis 1, a crushing mechanism 2, an extruding mechanism 4 and an adsorption mechanism 5. The crushing mechanism 2 is installed on the upper part of the chassis 1, and the extruding mechanism 4 is installed on the upper part of the crushing mechanism 2. The adsorption mechanism 5 is installed in the lower part of the crushing mechanism 2, and the crushing mechanism 2 is stabilized by the bottom frame 1, and then the nutrient material raw materials are poured into the crushing mechanism 2, and the extrusion mechanism 4 located above the crushing mechanism 2 first crushes the nutrient material raw materials. Squeeze to squeeze out the moisture in the nutrient raw materials, then crush the nutrient raw materials through the crushing mechanism, and when the crushed nutrient raw materials fall, they will pass through the adsorption mecha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap