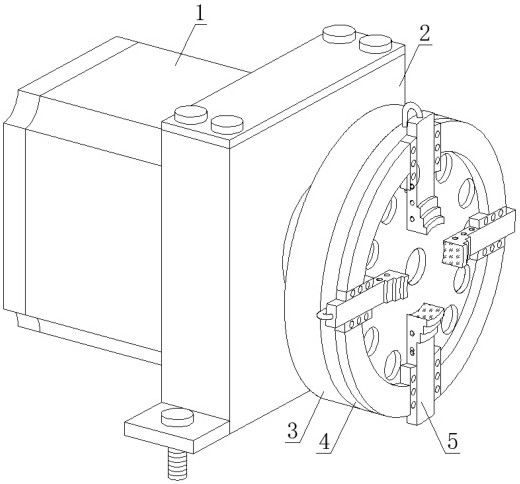

A CNC machine tool holder with a sealed degreasing mechanism and its implementation method

A technology of CNC machine tools and tool holders, which is applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc. It can solve the problems of oil mist, trouble removal, internal blockage, etc., and achieve easy clamping and locking, air flow speed, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

[0040] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a CNC machine tool holder with a sealed degreasing mechanism, comprising the following steps:

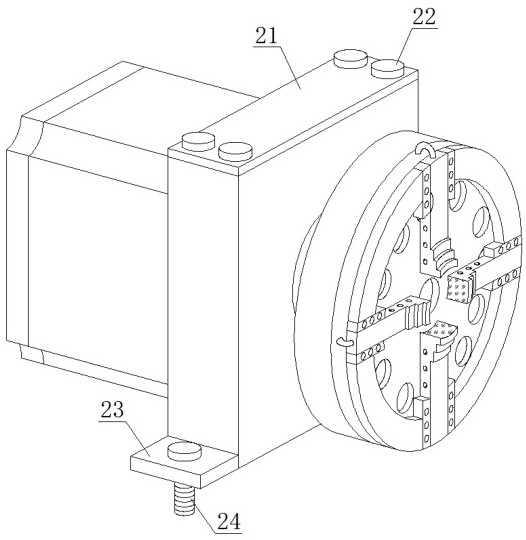

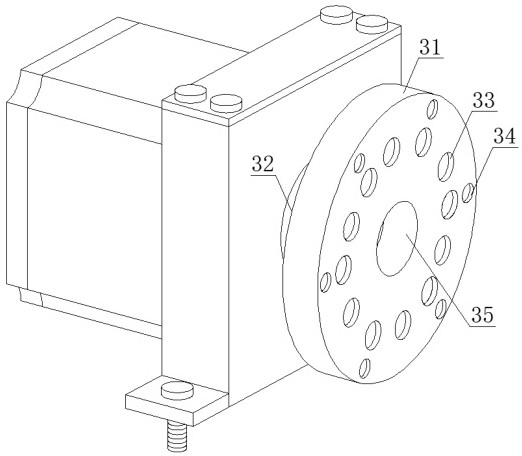

[0041] Step 1: Match the positioning column 43 fixedly installed at the rear end of the connection plate 41 with the positioning hole 34 to complete the positioning installation of the connection plate 41 and the cutter head body 31, and then use the bolt B24 to fix the device on the machine tool ;

[0042] Step 2: The shaft coupling 553 is connected to the motor, so that the shaft coupling 553 and the sleeve 552 rotate, which facilitates the rotation of the gear 551. During the rotation of the gear 551, the rack B58 can be driven to move left and right, that is, the vertical horizontal frame 57 can move left and right , the side of the vertical horizontal frame 57 close to the clamping block 53 is provided with an oblique rack 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com