Multi-mode hybrid drive system

A technology of hybrid power and drive system, which is applied to the layout of multiple prime movers of power plants, pneumatic power plants, and general-purpose power plants. It can solve problems such as poor layout, unstable battery life, and long charging time. Achieve good power performance and driving performance, improve energy recovery efficiency, and improve fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

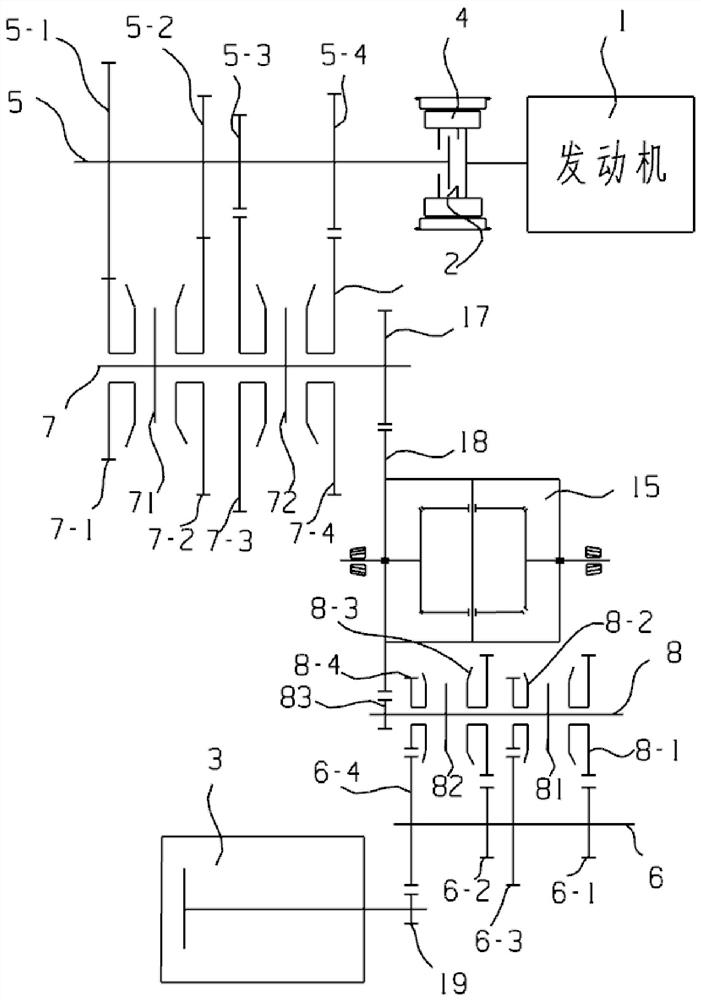

[0026] Such as figure 1 , the first transmission assembly mostly includes a first driving gear 5-1, a second driving gear 5-2, a third driving gear 5-3, a fourth driving gear 5-4, a first driven gear 7-1, a second driving gear Driven gear 7-2, the 3rd driven gear 7-3, the 4th driven gear 7-4, the first synchronizer 71, the second synchronizer 72, the first transmission gear 17, wherein, the first driving gear 5 -1, the second driving gear 5-2, the third driving gear 5-3, the fourth driving gear 5-4 are respectively fixed with the input shaft 5, the first driven gear 7-1, the second driven gear 7-2 , the third driven gear 7-3, and the fourth driven gear 7-4 are respectively vacantly sleeved on the intermediate shaft 7.

[0027] The first driving gear 5-1 meshes with the first driven gear 7-1 to form the first gear pair, and the second driving gear 5-2 meshes with the second driven gear 7-2 to form the second gear pair. The third driving gear 5-3 meshes with the third driven g...

Embodiment 2

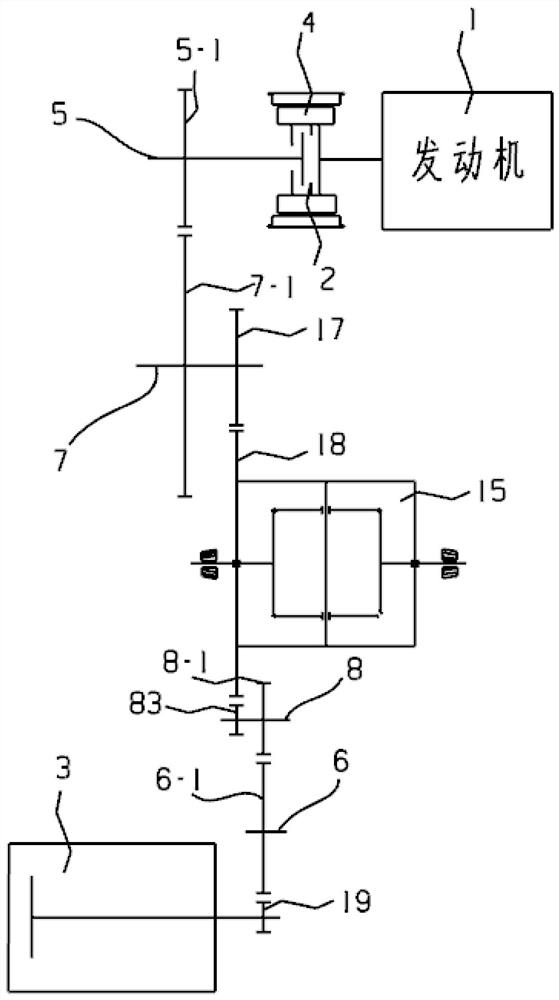

[0033] Such as figure 2 , the first transmission assembly mostly includes a first driving gear 5-1, a first driven gear 7-1, and a first transmission gear 17, wherein the first driving gear 5-1 is fixed to the input shaft 5, and the first driven gear 7-1 empty set on the intermediate shaft 7. The first driving gear 5-1 meshes with the first driven gear 7-1 to form the first gear pair, the first transmission gear 17 is fixed to the intermediate shaft 7, and the differential speed between the first transmission gear 17 and the differential 15 The gear input gear 18 meshes.

[0034] The second transmission assembly comprises input gear 19, first input gear 6-1, first intermediate gear 8-1, second transmission gear 83 more, input gear 19 is fixed with the output shaft of first motor 3, input gear 19 and the first One input gear 6-1 meshes, the first input gear 6-1 is fixed on the first transmission shaft 6, the first intermediate gear 8-1 is sleeved on the second transmission s...

Embodiment 3

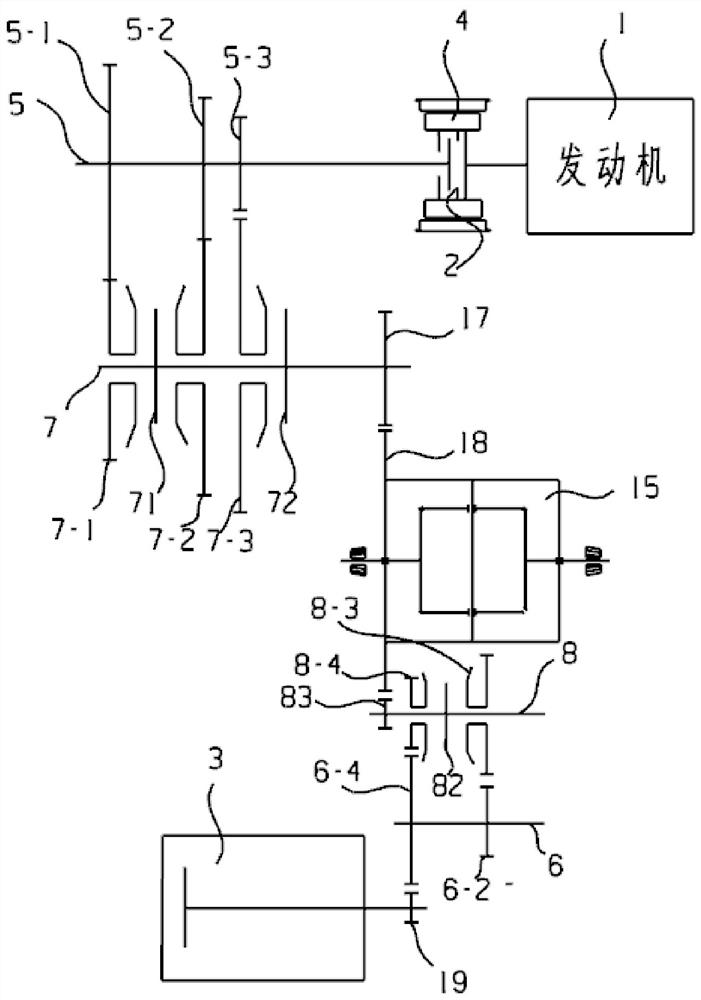

[0036] Such as image 3 , the first transmission assembly mostly includes a first driving gear 5-1, a second driving gear 5-2, a third driving gear 5-3, a first driven gear 7-1, a second driven gear 7-2, a Three driven gears 7-3, the first synchronizer 71, the second synchronizer 72, the first transmission gear 17, wherein, the first driving gear 5-1, the second driving gear 5-2, the third driving gear 5- 3 are respectively fixed with the input shaft 5, and the first driven gear 7-1, the second driven gear 7-2, and the third driven gear 7-3 are respectively vacantly sleeved on the intermediate shaft 7.

[0037] The first driving gear 5-1 meshes with the first driven gear 7-1 to form the first gear pair, and the second driving gear 5-2 meshes with the second driven gear 7-2 to form the second gear pair. The third driving gear 5-3 meshes with the third driven gear 7-3 to form a third gear pair.

[0038] The first synchronizer 71 is fixed on the intermediate shaft 7 and is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com