High-conductivity corrosion-resistant aluminum alloy monofilament for overhead conductor and preparation method of high-conductivity corrosion-resistant aluminum alloy monofilament

A technology of aluminum alloy monofilament and aluminum alloy, which is applied in the field of overhead conductors of transmission lines in the electric power industry, can solve the problems of large transmission loss, low conductivity, and weak corrosion resistance, and achieve low cost, high conductivity, and simplified preparation The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

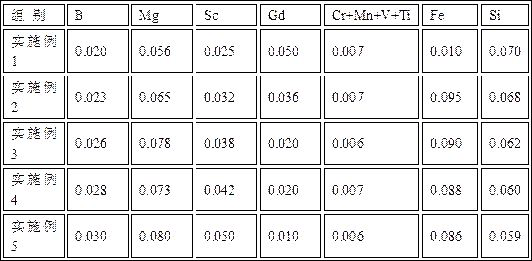

Embodiment 1

[0033] An aluminum alloy monofilament material, the components and their mass percentages are:

[0034] B 0.020%

[0035] Mg 0.056%

[0036] Sc 0.025%

[0037] Gd 0.050%

[0038] Cr+Mn+V+Ti 0.007%

[0039] Fe 0.010%

[0040] Si 0.070%

[0041] Al and unavoidable impurity balance.

[0042] Its preparation method is as follows:

[0043] Step 1. Add various alloying elements to industrial pure aluminum with a purity of 99.85% Al, so that their final content is as shown above. The alloying elements are based on Al-B, Al-Mg, Al-Sc, Al-Gd master alloys The form is added in a frequency induction furnace for smelting, and the melting temperature is kept at 730°C. After the aluminum ingot is completely melted, the Al-B intermediate alloy is added at 740°C for boronization treatment; ℃, add Al-Mg master alloy, Al-Sc master alloy and Al-Gd master alloy in turn. After the master alloy is completely melted, electromagnetically stir the aluminum alloy solution for 15 minutes each ti...

Embodiment 2

[0050] An aluminum alloy monofilament material, the components and their mass percentages are:

[0051] B 0.023%

[0052] Mg 0.065%

[0053] Sc 0.032%

[0054] Gd 0.036%

[0055] Cr+Mn+V+Ti 0.007%

[0056] Fe 0.095%

[0057] Si 0.068%

[0058] Al and unavoidable impurity balance.

[0059] Its preparation method is as follows:

[0060] Step 1. Add various alloying elements to industrial pure aluminum with a purity of 99.85% Al, so that their final content is as shown above. The alloying elements are based on Al-B, Al-Mg, Al-Sc, Al-Gd master alloys The form is added in a frequency induction furnace for melting, and the melting temperature is kept at 740°C. After the aluminum ingot is completely melted, the Al-B intermediate alloy is added at 745°C for boronization treatment; ℃, add Al-Mg master alloy, Al-Sc master alloy and Al-Gd master alloy in turn. After the master alloy is completely melted, electromagnetically stir the aluminum alloy solution for 20 minutes each tim...

Embodiment 3

[0067] An aluminum alloy monofilament material, the components and their mass percentages are:

[0068] B 0.026%

[0069] Mg 0.078%

[0070] Sc 0.038%

[0071] Gd 0.020%

[0072] Cr+Mn+V+Ti 0.006%

[0073] Fe 0.009%

[0074] Si 0.062%

[0075] Al and unavoidable impurity balance.

[0076] Its preparation method is as follows:

[0077] Step 1. Add various alloying elements to industrial pure aluminum with a purity of 99.85% Al, so that their final content is as shown above. The alloying elements are based on Al-B, Al-Mg, Al-Sc, Al-Gd master alloys The form is added in a frequency induction furnace for melting, and the melting temperature is kept at 740°C. After the aluminum ingot is completely melted, the Al-B intermediate alloy is added at 750°C for boronization treatment; ℃, add Al-Mg master alloy, Al-Sc master alloy and Al-Gd master alloy in turn. After the master alloy is completely melted, electromagnetically stir the aluminum alloy solution for 20 minutes each tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com