A kind of negative ion fabric and preparation method thereof

A technology of negative ions and fabrics, which is applied in the direction of furnace types, dry solid materials, lighting and heating equipment, etc., can solve the problems of fabric loss, negative ion failure, weaving condition restrictions, etc., to achieve enhanced friction, enhanced stability, and improved resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

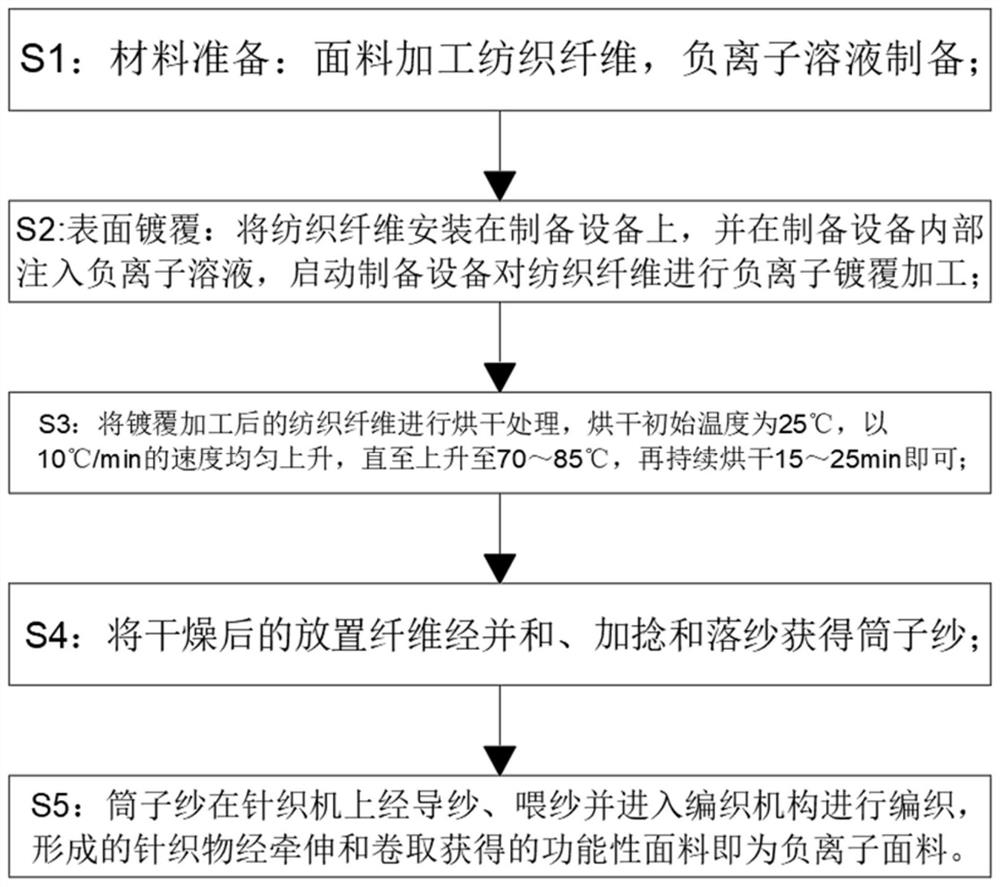

[0044] see figure 1 , the present invention provides a technical solution: a preparation method of negative ion fabric, comprising the following steps,

[0045] S1: Material preparation: fabric processing textile fibers, negative ion solution preparation;

[0046] S2: surface plating: the textile fibers are installed on the preparation equipment, and an anion solution is injected into the preparation equipment, and the preparation equipment is started to perform anion plating processing on the textile fibers;

[0047] S3: Dry the coated textile fibers. The initial drying temperature is 25°C, and it is evenly increased at a rate of 10°C / min until it rises to 70-85°C, and then continues to dry for 15-25 minutes. ;

[0048] S4: combining, twisting and doffing the dried placed fibers to obtain cheese;

[0049] S5: The package yarn is guided and fed on the knitting machine and enters the knitting mechanism for weaving. The formed knitted fabric is drawn and wound to obtain a fun...

Embodiment 2

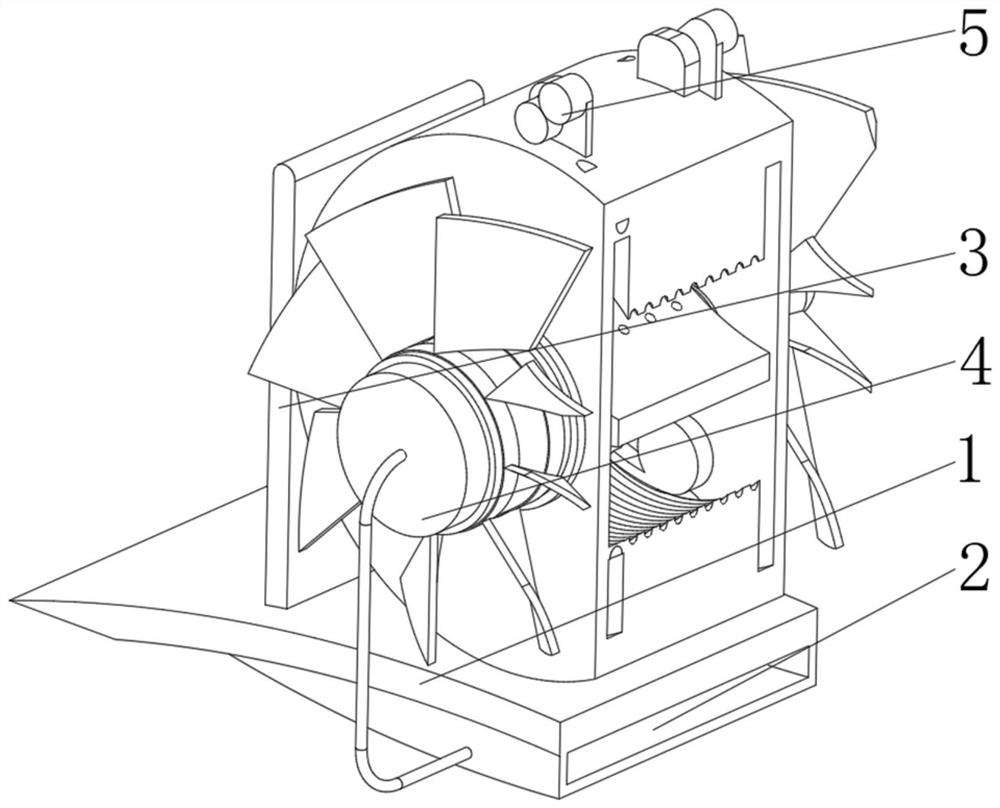

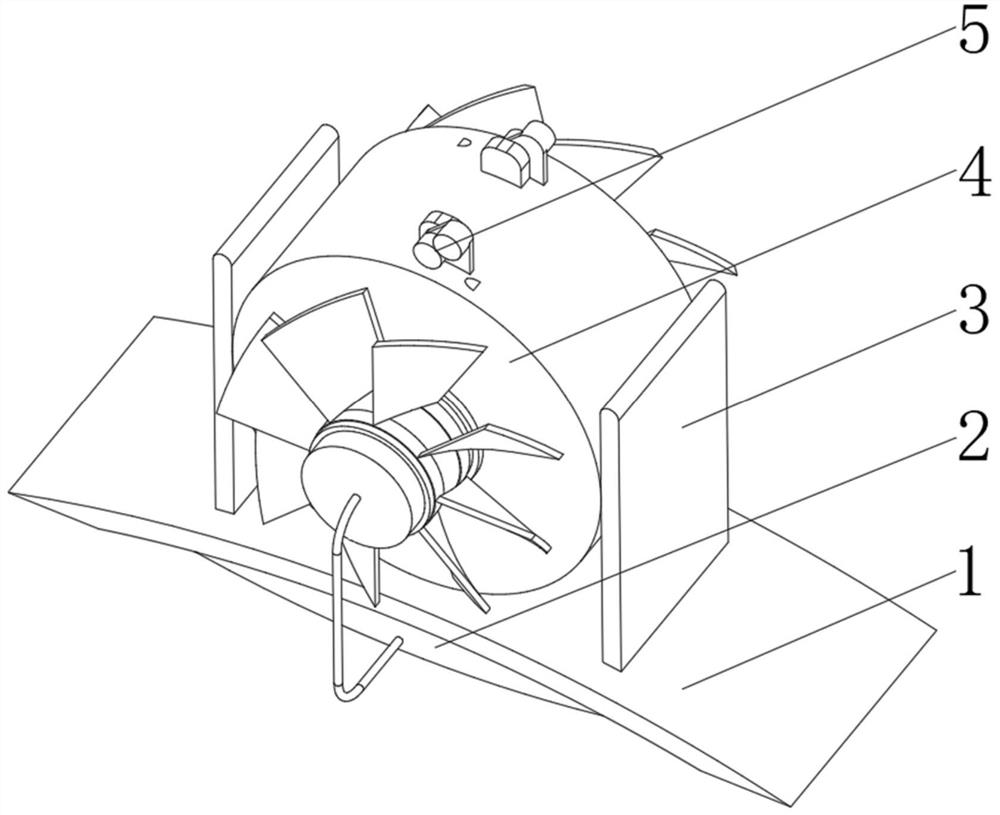

[0051] see Figure 2-7 , the present invention provides a technical solution: a preparation equipment for negative ion fabrics, specifically comprising:

[0052] Seat plate 1, the seat plate 1 has an arc-shaped plate body, and a liquid tank 2 installed at the bottom of the arc-shaped plate body, and shelf plates 3 installed on both sides of the top of the arc-shaped plate body, and the shelf plates 3 are installed close to each other The plating device 4 in the middle position on one side, and the wire guide 5 installed on the top of the outer surface of the plating device 4 in the middle position between the front and the back, and the arc-shaped seat plate 1 is set to disperse the impact force generated when the equipment itself is running , to avoid wear of the seat plate 1 due to the impact force, and at the same time, its own arc-shaped setting disperses the impact force to the contact surface with the ground, strengthens the friction force of the equipment, and enhances ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com