Method for detecting focus in femtosecond laser processing by using image sensor and application thereof

A femtosecond laser processing and image sensor technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of indistinguishable electrical signal changes, large detection errors, etc., to achieve strong repeatability, good robustness, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Focus detection on the sapphire horizontal surface is performed with an image sensor.

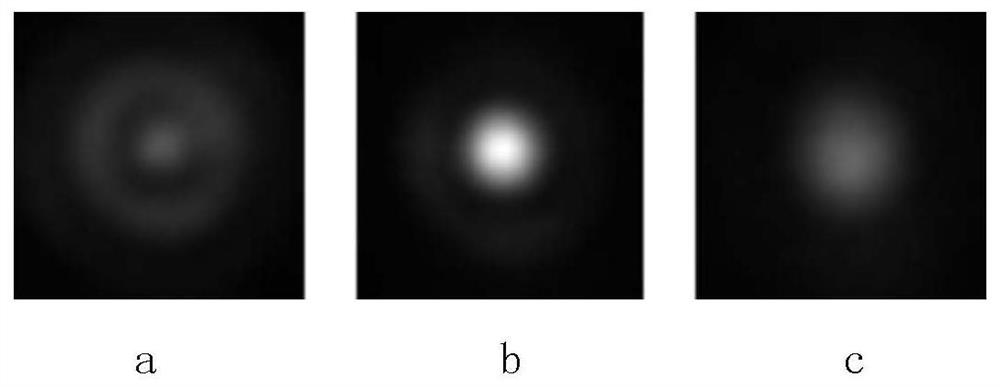

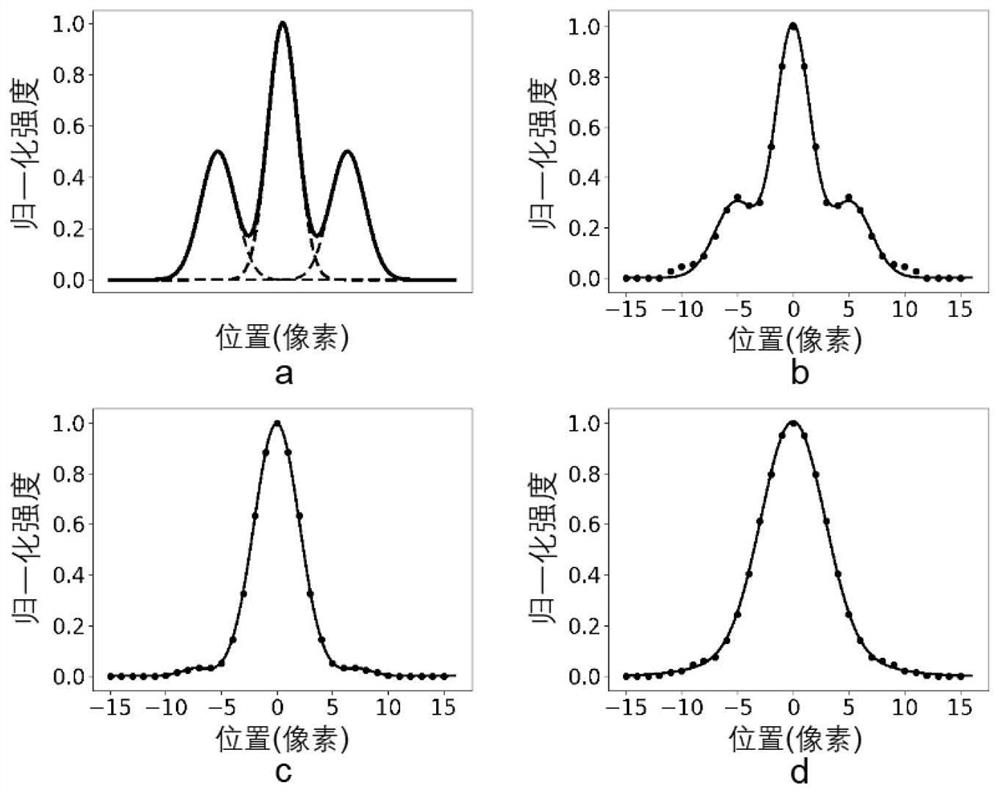

[0035] By using a computer program to analyze the reflected light focus image obtained by the image sensor, the out-of-focus position and direction at this time are obtained. Then by moving the z-axis translation stage to move the laser focusing point to the sapphire surface accurately, the defocus problem in laser processing can be effectively solved.

[0036] A method for detecting focus in femtosecond laser processing using an image sensor, the specific steps are as follows:

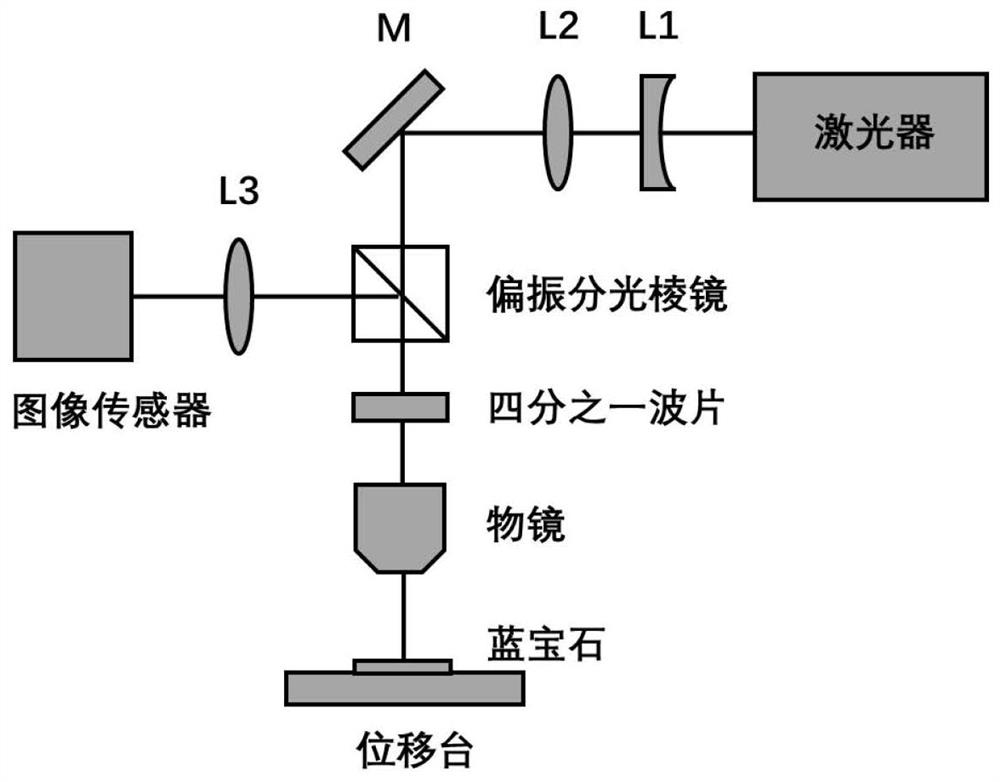

[0037] (1) Reflection spot image acquisition: Using the properties of the polarization beam splitter prism, combined with a quarter-wave plate, the reflected light on the sapphire surface is separated for detection. The wavelength of the femtosecond laser used is 1030nm. The laser beam emitted by the femtosecond laser is expanded by the first concave lens L1 and the second convex lens L2, and the spot is ex...

Embodiment 2

[0052] The application of the focus detection method to the uniform processing of large-scale micro-nanostructures on inclined sapphire surfaces.

[0053] Select four positions on the inclined sapphire surface for focus detection by the focus detection method, and the z-axis coordinates of the four points on the sapphire surface that are square in the xy plane can be obtained, and the morphology of the inclined sapphire surface can be drawn through these coordinates. By improving the processing procedure, the focus during processing can be kept on the sapphire, and finally a large-sized uniform micro-nano structure can be obtained.

[0054] The focus detection method is applied to the uniform processing of large-scale micro-nano structures on the inclined sapphire surface. The specific steps are as follows:

[0055] Steps (1), (2) are the same as in Example 1.

[0056] (3) Draw the morphology of the sapphire slope:

[0057] Place the sapphire to be tested on the sample stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com