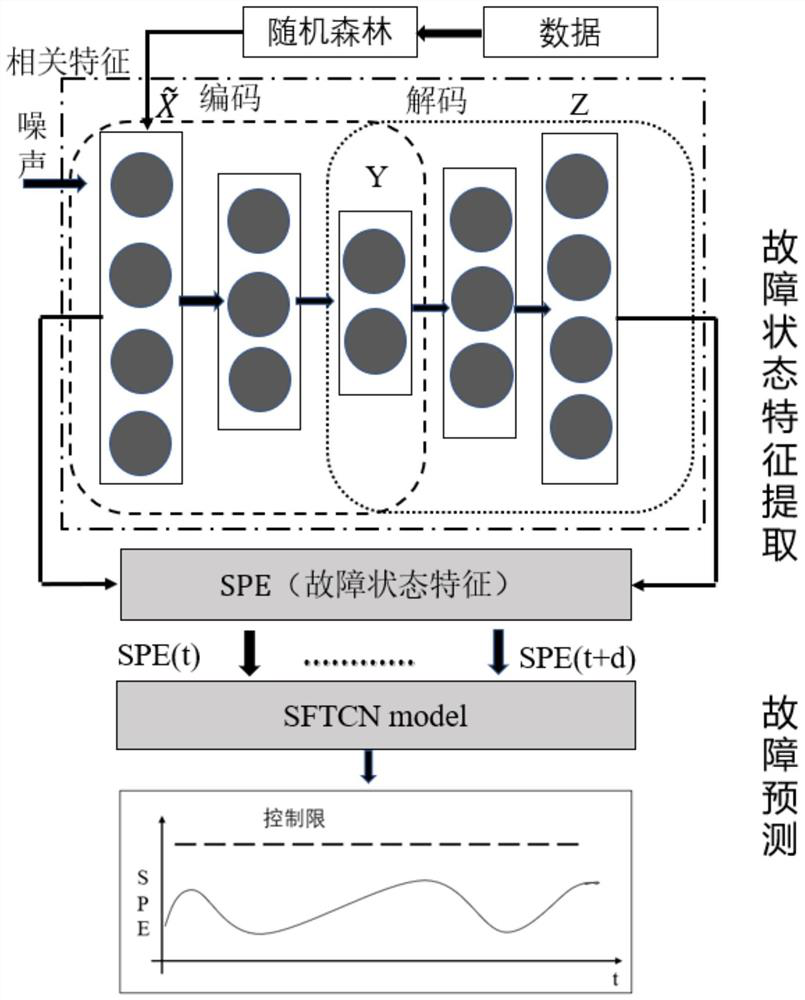

Complex industrial process fault prediction method based on RF noise reduction self-encoding information reconstruction and time convolution network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] According to the actual chemical reaction process, American Eastman Chemical Company has developed an open and challenging chemical model simulation platform - Tennessee Eastman (TE) simulation platform. The TE chemical process is a prototype of an actual process flow. The whole process includes 5 main operating units, namely reactor, condenser, cycle compressor, gas-liquid separator and product desorption tower. The data generated by it have time-varying and strong coupling and nonlinear features, widely used for testing control and fault diagnosis models of complex industrial processes.

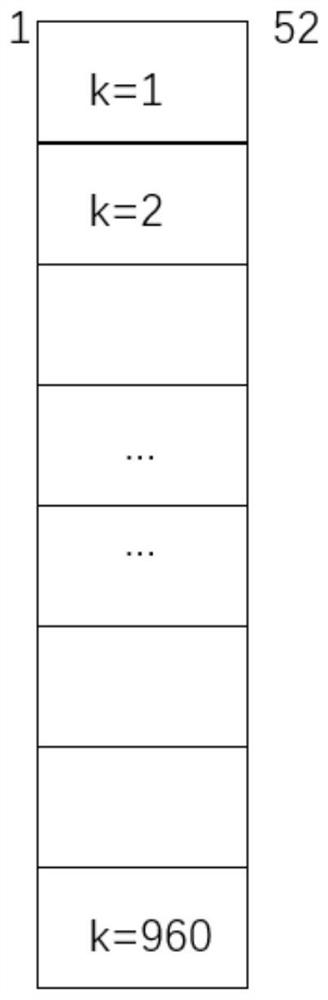

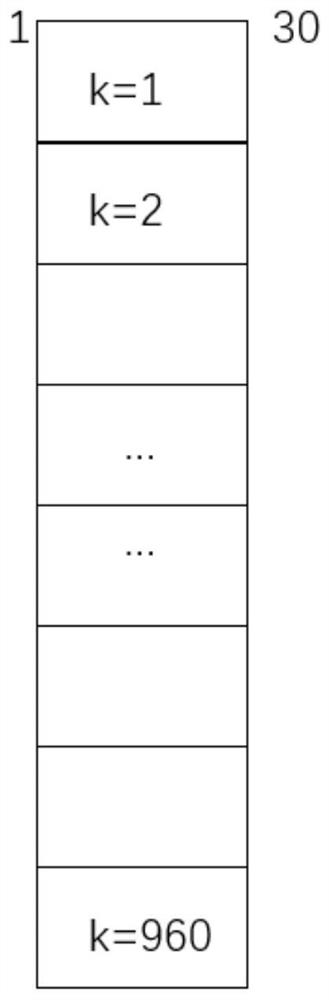

[0078] There are 41 measured variables and 12 manipulated variables in the TE process, and 21 fault types are set. The 12th manipulated variable XMV(12) remains unchanged throughout the process and is not used as input data. Select 52 variables [XMEAS(1), ..., XMEAS(41), XMV(1), ..., XMV(11)] as the original observation signal vector at a specific moment. In the simulation experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com