Waste heat removal system and method and nuclear power system

A technology of waste heat discharge system and coolant system, applied in the field of nuclear power system, can solve the problems of complex device and poor reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

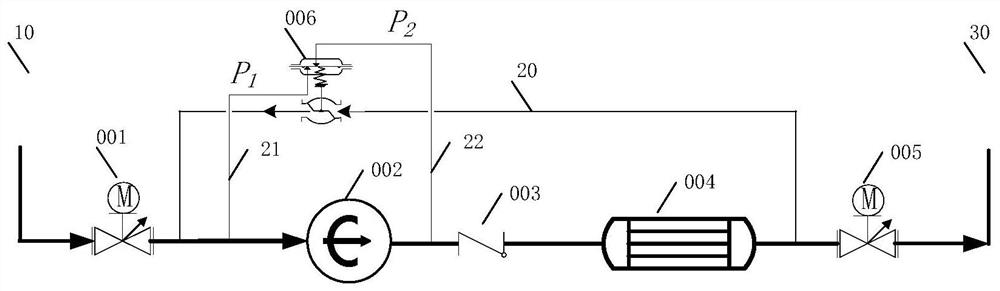

[0051] Such as figure 1 As shown, this embodiment provides a waste heat removal system, including: a main pipe, a small flow pipe 20, a pressure taking pipe 21 before the pump, and a pressure taking pipe 22 after the pump,

[0052] The main pipe is connected between the hot section 10 and the cold section 30 of the reactor coolant system loop, and along the coolant flow direction from the hot section 10 to the cold section 30, the main pipe is provided with a first isolation valve 001, a circulation pump 002, a heat exchange device 004 and second isolation valve 005,

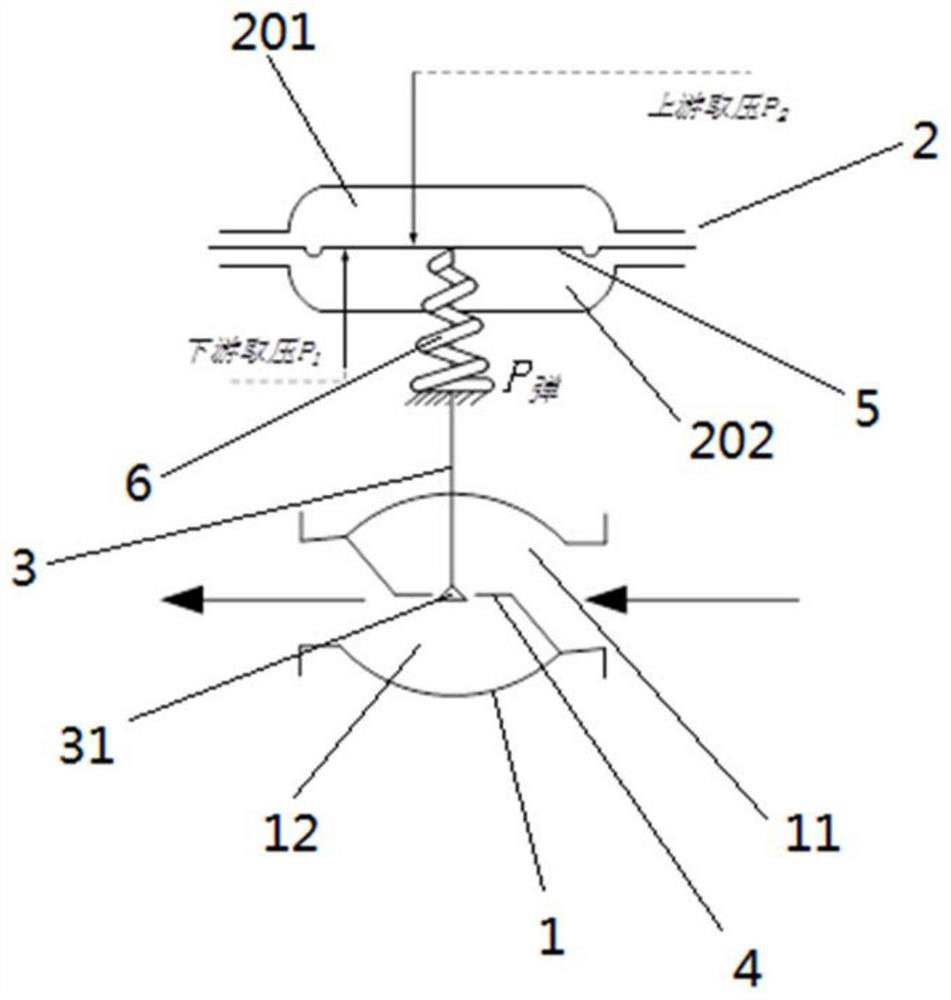

[0053] The small flow pipe 20 is connected between the first communication port of the main pipe and the second communication port. The first communication port is between the first isolation valve 001 and the circulation pump 002. The position between the two isolation valves 005, the small flow pipe 20 is provided with a self-operated differential pressure regulating valve 006,

[0054] The circulating pump ...

Embodiment 2

[0080] This embodiment provides a method for utilizing the system of Embodiment 1 to discharge waste heat in the reactor coolant system, comprising the following steps:

[0081] Open the first isolation valve 001, close the second isolation valve 005, so that the main pipe communicates with the small flow pipe 20, start the circulation pump 002, and use the power of the circulation pump 002 to transfer the coolant in the circulation formed by the small flow pipe 20 and the main pipe. heating to the set value,

[0082] Open the second isolation valve 005 to disconnect the main pipe from the small flow pipe 20, and form a circulation with the reactor coolant system, and pump the coolant in the hot section 10 of the loop of the reactor coolant system through the power of the circulation pump 002 After being cooled in the heat exchanger 004, it is sent to the hot section 10 of the reactor coolant system loop.

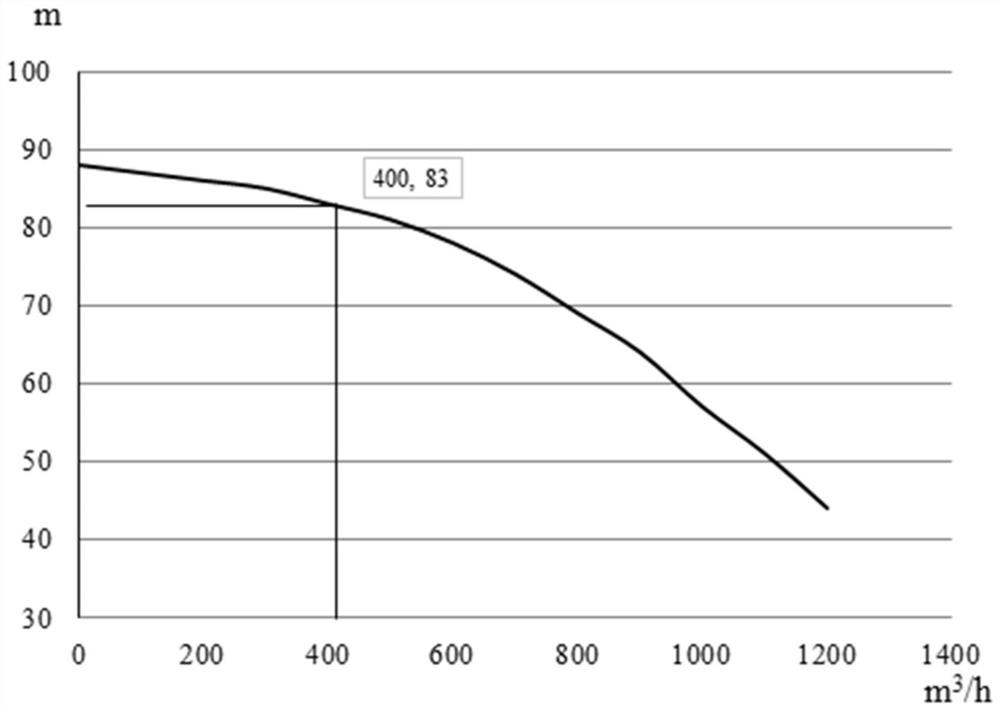

[0083] Taking the waste heat discharge system adopted in a certain po...

Embodiment 3

[0085] This embodiment provides a nuclear power system, including a reactor coolant system and the waste heat removal system of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com