High-temperature-resistant self-powered wide bandgap power device driving control circuit

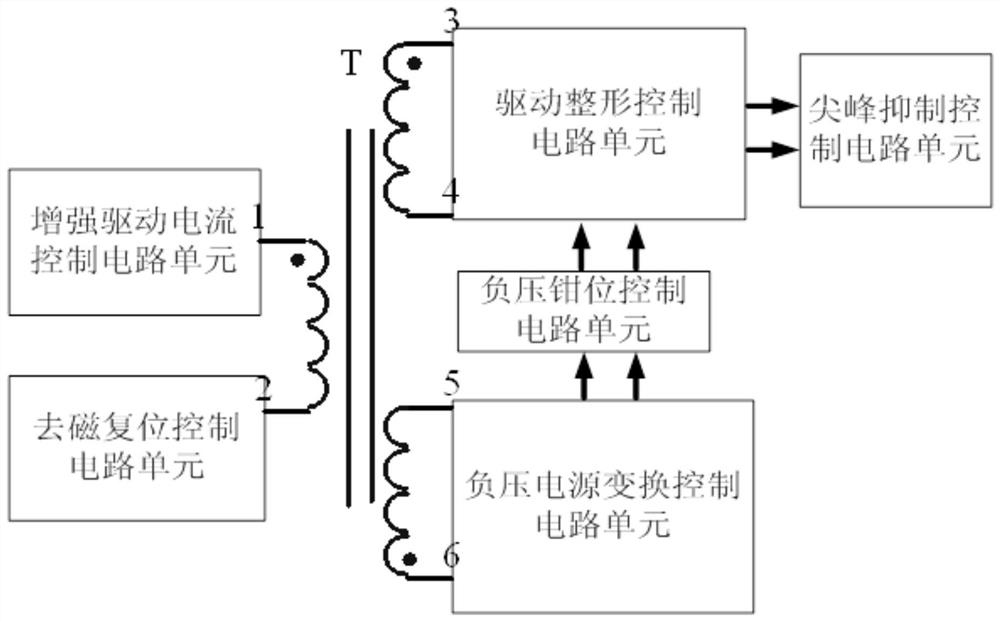

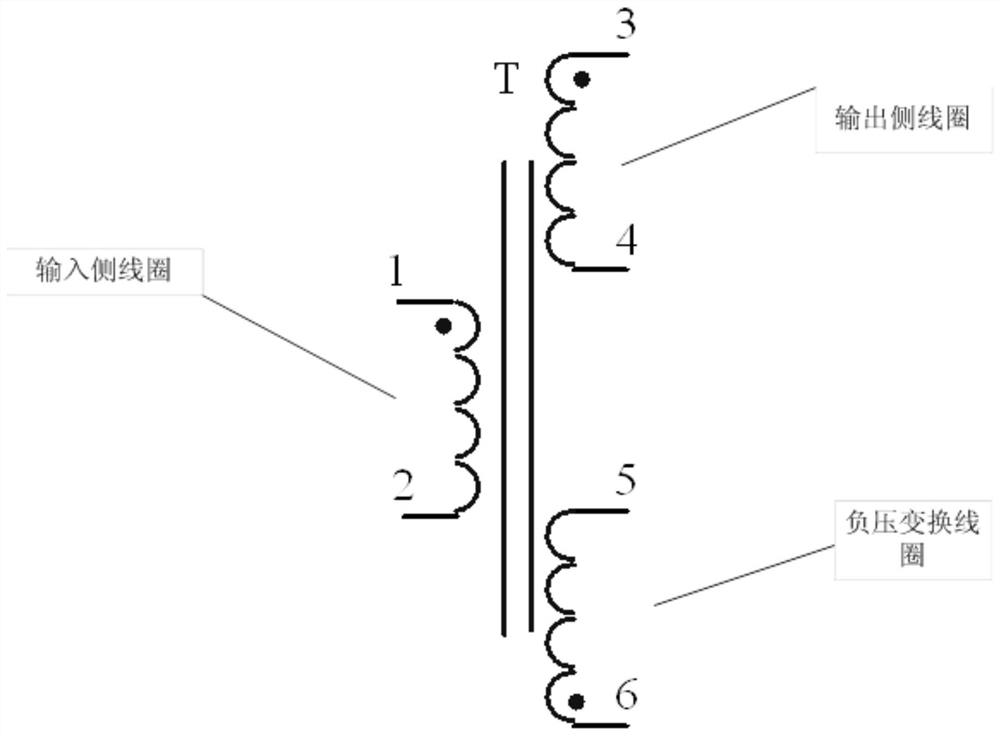

A technology for driving control circuits and control circuits, applied to circuits, electrical components, control/regulation systems, etc., to achieve high-frequency, high-reliability shutdown control, small volume, and reduced number of coil turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

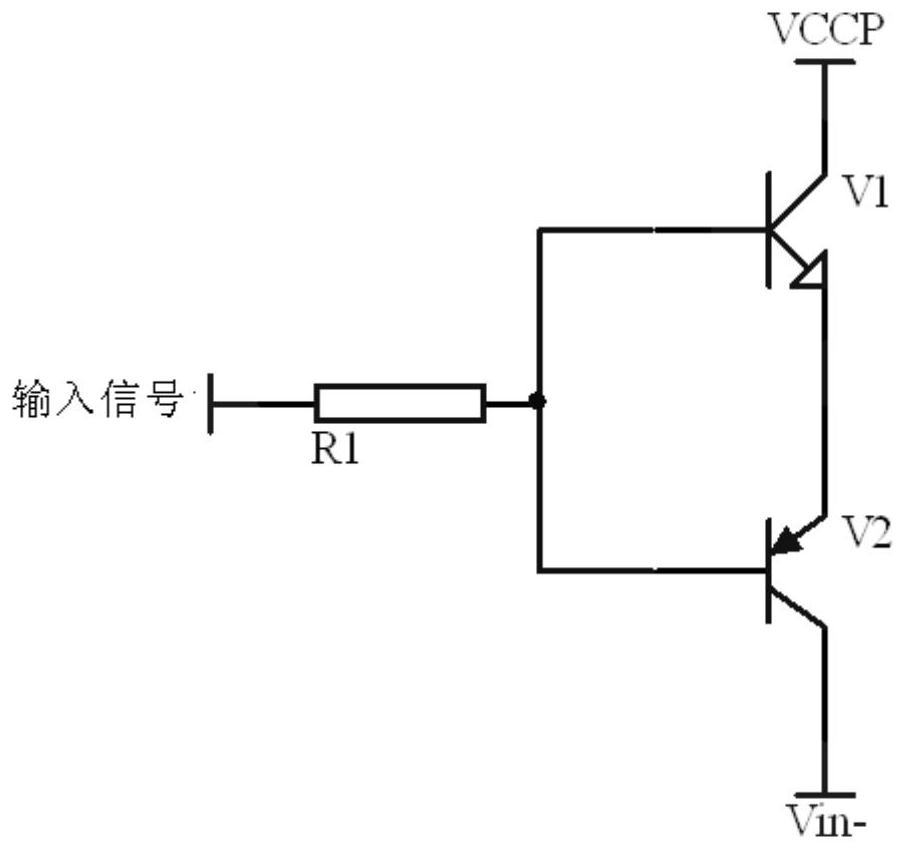

[0043] Such as image 3 As shown, the enhanced driving current control circuit unit includes a resistor R1, an NPN transistor V1, and a PNP transistor V2;

[0044] The input signal to control the wide bandgap power device is connected to one end of the resistor R1, the other end of the resistor R1 is connected to the base of the transistor V1 and the base of the transistor V2, the collector of the transistor V1 is connected to the self-powered VCCP, the emitter of the transistor V1 is connected to the emitter of the transistor V2, and the transistor The collector of V2 is connected to the input side ground signal -Vin, and the emitter of the triode V1 is connected to pin 1 of the input side coil of the integrated drive conversion transformer with the same name.

[0045] Such as Figure 4 As shown, the demagnetization reset control circuit unit includes a resistor R2, a resistor R3, a resistor R4, a resistor R5, a MOS transistor Q1, and a MOS transistor Q2;

[0046] The reset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com