CuCo-BDC ultrathin nanosheet, preparation method and application thereof

A nanosheet, ultra-thin technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex operation, poisonous and harmful, low yield, etc., and achieve simple operation and high conductivity , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of 10Cu / 90Co-BDC ultra-thin nanosheets specifically comprises the following steps:

[0029] First, dissolve 125.86mg of terephthalic acid in a mixed solution of 12ml N,N-dimethylformamide, 2ml of absolute ethanol, and 2ml of deionized water, then dissolve 10ml of N,N-dimethylformamide solution Add 12.91mg of copper chloride dihydrate and 162mg of cobalt chloride hexahydrate dissolved in 10ml of N,N-dimethylformamide solution to the above solution in sequence, and after ultrasonication, add dropwise at a rate of 48ml / h while stirring the above solution Triethylamine, after stirring for five minutes, stop the dropwise addition, ultrasonic for 8 hours, use ethanol at 2500r / min to centrifuge and wash 3 times, then dry in an oven at 80°C to obtain pink powder 10Cu / 90Co-BDC ultrathin nanosheets.

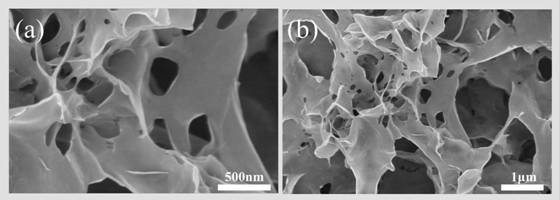

[0030] figure 1 Low-magnification (a) and high-magnification (b) FESEM images of the bimetallic organic framework 10Cu90Co-BDC prepared for this example, th...

Embodiment 2

[0032] The preparation method of 30Cu / 70Co-BDC ultra-thin nanosheets, the specific steps are similar to Example 1, the difference is that the mass of copper chloride dihydrate is 38.75 mg, and the mass of cobalt chloride hexahydrate is 126.17 mg.

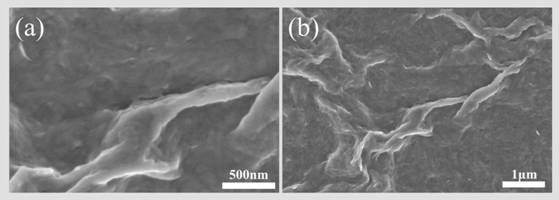

[0033] figure 2 The low-magnification (a) and high-magnification (b) FESEM photos of the bimetallic organic framework 30Cu70Co-BDC prepared for this example, compared with 10Cu90Co-BDC, the three-dimensional sense of space becomes worse, and the thickness also increases.

Embodiment 3

[0035] The preparation method of Cu-BDC ultra-thin nanosheets specifically comprises the following steps:

[0036] First, dissolve 125.86mg of terephthalic acid in a mixed solution of 12ml N,N-dimethylformamide, 2ml of absolute ethanol, and 2ml of deionized water, and then dissolve 20ml of N,N-dimethylformamide solution 129.15 mg of copper chloride dihydrate was added to the above solution, and after ultrasonication was uniform, triethylamine was added dropwise to the above mixed solution at a rate of 48ml / h, stirred for five minutes, ultrasonicated for 8 hours, and centrifuged with ethanol at a speed of 2500r / min for 3 After drying in an oven at 80°C, powdered Cu-BDC ultrathin nanosheets were obtained.

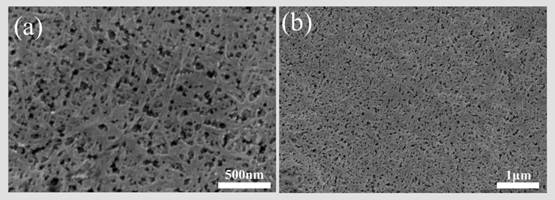

[0037] image 3 Low-magnification (a) and high-magnification (b) FESEM images of the metal-organic framework Cu-BDC prepared for this example, and its morphology is a uniform ribbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com