High-capacity positive lead paste and preparation method thereof

A positive electrode paste, high-capacity technology, applied in the direction of electrode manufacturing, battery electrodes, lead-acid batteries, etc., can solve the problems of low specific energy by weight, the weight of the positive plate of lead-acid batteries cannot be reduced, and the utilization rate of positive active materials is low. , to prolong the cycle life, increase the electrochemical reaction area, and facilitate the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

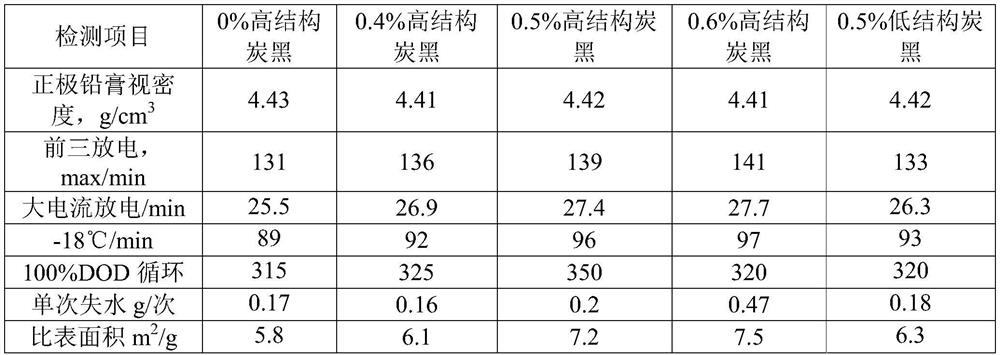

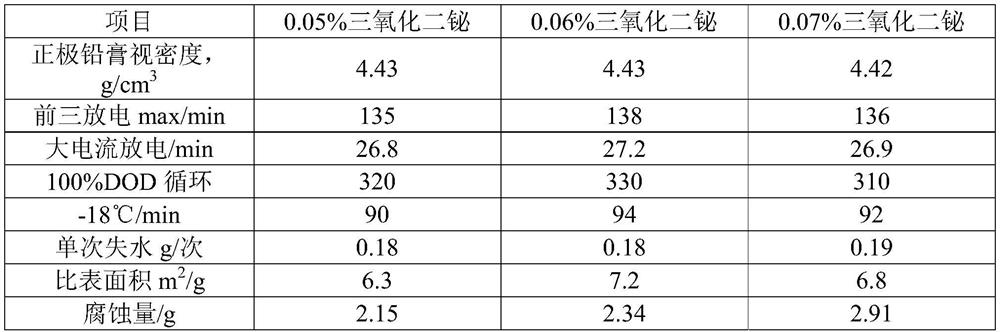

[0017] A high-capacity positive electrode paste prepared from the following raw materials: 100Kg lead powder, 8.5Kg sulfuric acid, 14Kg deionized water, 0.15Kg antimony trioxide, 0.05Kg bismuth trioxide, 0.02Kg zinc oxide , 0.08Kg polyester staple fiber, 0.4Kg high structure carbon black, 0.1Kg red lead.

[0018] The preparation process is as follows: pre-mix antimony trioxide, bismuth trioxide, zinc oxide, polyester staple fiber, and red lead with a high-speed mixer for 12-15 minutes; then add half of the lead powder to the paste mixer, and Sprinkle the premixed material and high-structure carbon black evenly on the surface of the lead powder, stir for 5-8 minutes, add the other half of the lead powder, and continue stirring for 15-20 minutes; then quickly add deionized water, and continue stirring for 10-15 minutes; finally add Sulfuric acid, control the acid addition time to be 16-20min, and continue to stir for 13-15min after the acid addition, to obtain the positive elect...

Embodiment 2

[0021] A high-capacity positive electrode paste prepared from the following raw materials: 100Kg lead powder, 8.5Kg sulfuric acid, 14Kg deionized water, 0.25Kg antimony trioxide, 0.07Kg bismuth trioxide, 0.03Kg zinc oxide , 0.1Kg polyester staple fiber, 0.6Kg high structure carbon black, 0.3Kg red lead.

[0022] The preparation process is as follows: pre-mix antimony trioxide, bismuth trioxide, zinc oxide, polyester staple fiber, and red lead with a high-speed mixer for 12-15 minutes; then add half of the lead powder to the paste mixer, and Sprinkle the premixed material and high-structure carbon black evenly on the surface of the lead powder, stir for 5-8 minutes, add the other half of the lead powder, and continue stirring for 15-20 minutes; then quickly add deionized water, and continue stirring for 10-15 minutes; finally add Sulfuric acid, control the acid addition time to be 16-20min, and continue to stir for 13-15min after the acid addition, to obtain the positive electr...

Embodiment 3

[0025] A high-capacity positive electrode paste prepared from the following raw materials: 100Kg lead powder, 8.5Kg sulfuric acid, 14Kg deionized water, 0.2Kg antimony trioxide, 0.06Kg bismuth trioxide, 0.025Kg zinc oxide , 0.09Kg polyester staple fiber, 0.5Kg high structure carbon black, 0.2Kg red lead.

[0026] The preparation process is as follows: pre-mix antimony trioxide, bismuth trioxide, zinc oxide, polyester staple fiber, and red lead with a high-speed mixer for 12-15 minutes; then add half of the lead powder to the paste mixer, and Sprinkle the premixed material and high-structure carbon black evenly on the surface of the lead powder, stir for 5-8 minutes, add the other half of the lead powder, and continue stirring for 15-20 minutes; then quickly add deionized water, and continue stirring for 10-15 minutes; finally add Sulfuric acid, the acid addition time is controlled to be 16-20min, and the stirring is continued for 13-15min after the acid addition is completed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com