Trichosanthes kirilowii seed stir-frying equipment for processing trichosanthes

A technology for stir-frying of Trichosanthes seeds, which is applied in the field of Trichosanthes seeds stir-frying equipment for Trichosanthes processing, can solve the problems of increasing the cost of frying, achieve the effects of reducing the cost of frying, realizing recycling, and facilitating management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

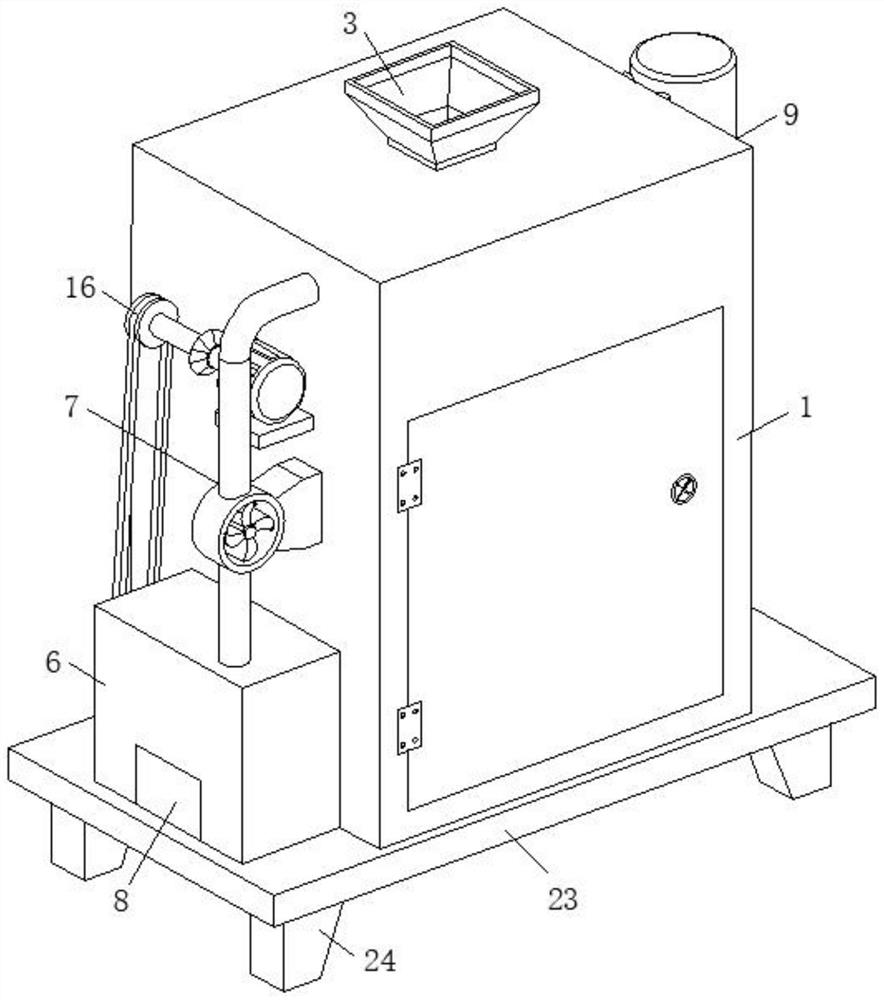

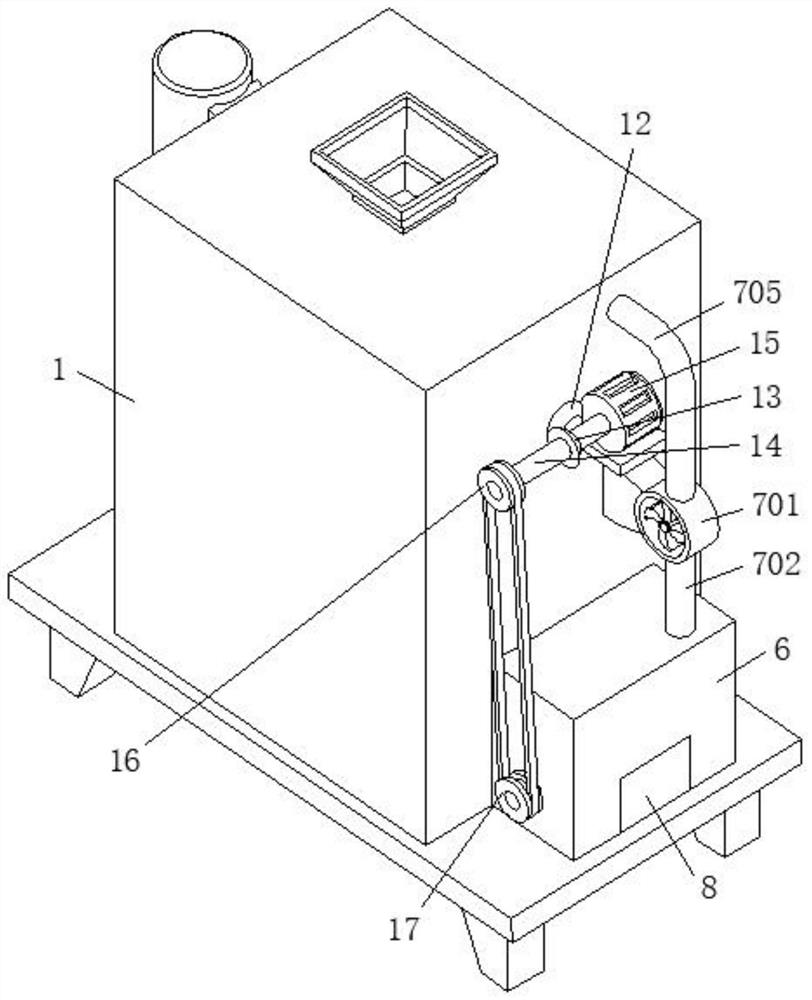

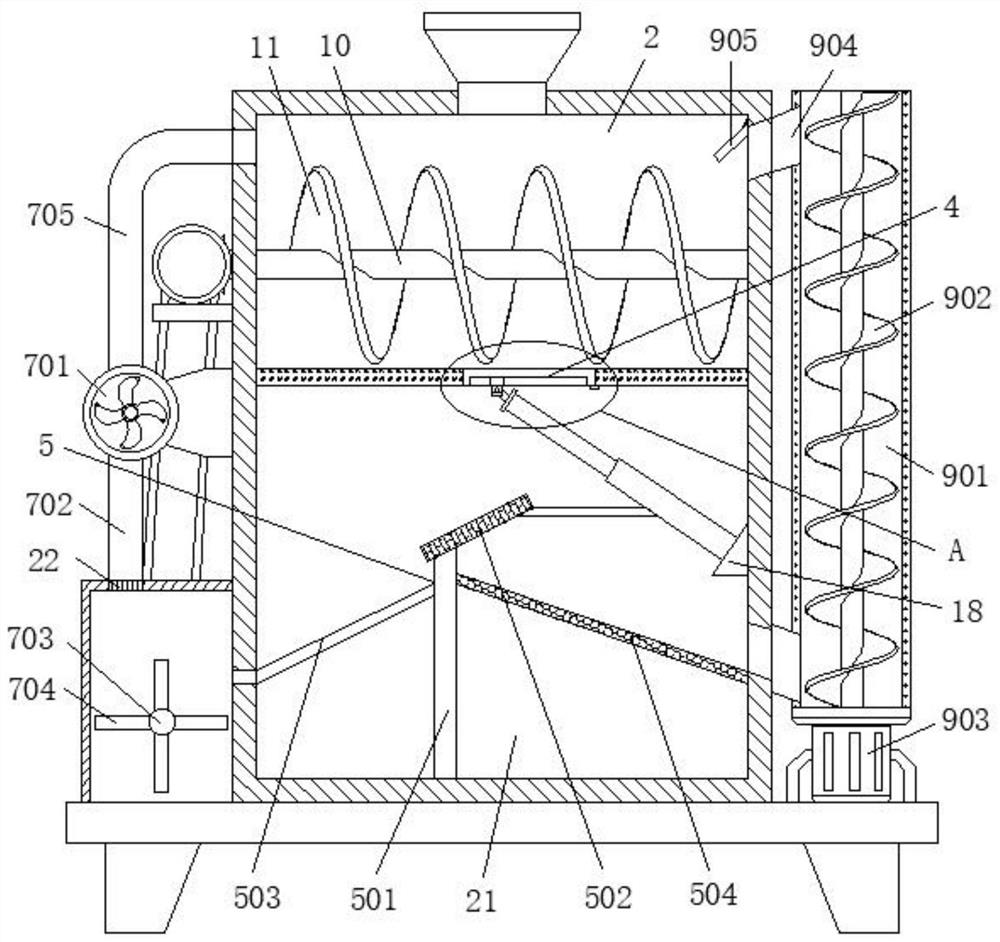

[0032] refer to Figure 1-5 , a melon seed stir-frying equipment for melon processing, comprising a box body 1, a box door is hinged on the front side plate of the box body 1 through hinges, which is convenient for the maintenance of the internal parts of the box body 1. A horizontally arranged stir-frying cylinder 2 is fixedly installed on the inner top wall, and a feeding hopper 3 that is communicated with the stirring-frying cylinder 2 is fixedly installed on the top of the box body 1, through which the melon seeds are poured into the stir-frying The inside of the drum 2 is stir-frying, and the right side wall of the strip hole at the bottom of the stir-fry drum 2 is hinged with a discharge plate 4 for discharging after the stir-frying is completed, and the lower part of the stir-fry drum 2 is provided with a useful For the screening mechanism 5 for separating the melon seeds and the gravel, the left side wall of the box body 1 is fixedly connected with a cooling box 6 for ...

Embodiment 2

[0037] like image 3 and Figure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a triangular block 18 is fixedly installed on the inner side wall of the box body 1, and an electric telescopic rod 19 is fixedly installed on the triangular block 18, and the end of the electric telescopic rod 19 passes through A sliding block 20 is hinged on the hinge support, and the sliding block 20 is matched with the sliding rail at the bottom of the stripper plate 4 .

[0038] In this embodiment, the electric telescopic rod 19 drives the sliding block 20 to slide in the slide rail at the bottom of the discharge plate 4 and drives the discharge plate 4 to rotate during the retraction process of the electric telescopic rod 19, so as to realize the discharge of the melon seeds inside the stir-frying cylinder 2, and vice versa. , when the electric telescopic rod 19 is extended, it drives the discharge plate 4 to rotate in the reverse direction until the stir-fryi...

Embodiment 3

[0040] like image 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the screening mechanism 5 includes a support plate 501 that is fixedly installed on the inner bottom wall of the box body 1. The top of the support plate 501 is fixedly installed with an inclined screen plate. 502, and the left and right side walls of the support plate 501 are respectively fixed with inclined guide plates 503 and two sieve plates 504, the sieve holes of the second sieve plate 504 are smaller than those of the first sieve plate 502, and the second sieve plate Below 504 is provided a dust collection chamber 21 for collecting dust.

[0041] In this embodiment, when the fried melon seeds are dropped from the stir-frying cylinder 2 to the sieve plate one 502, the melon seeds and the sand can be separated, and the separated sand can be dropped to the second sieve plate 504. On the screen, the dust in the sand and gravel is screened out by the sieve plate 2 504 to reduc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap