Constant-pressure and constant-temperature heat exchange system

A technology of heat exchange system and heat exchanger, applied in the direction of heat exchanger types, indirect heat exchangers, heat storage equipment, etc., can solve the problems of unsteady outlet water temperature, output hot water being vaporized, difficulty in procurement, etc., and achieve structural Simple, long-lasting, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The following description is only for demonstration and explanation, and does not limit the present invention in any form.

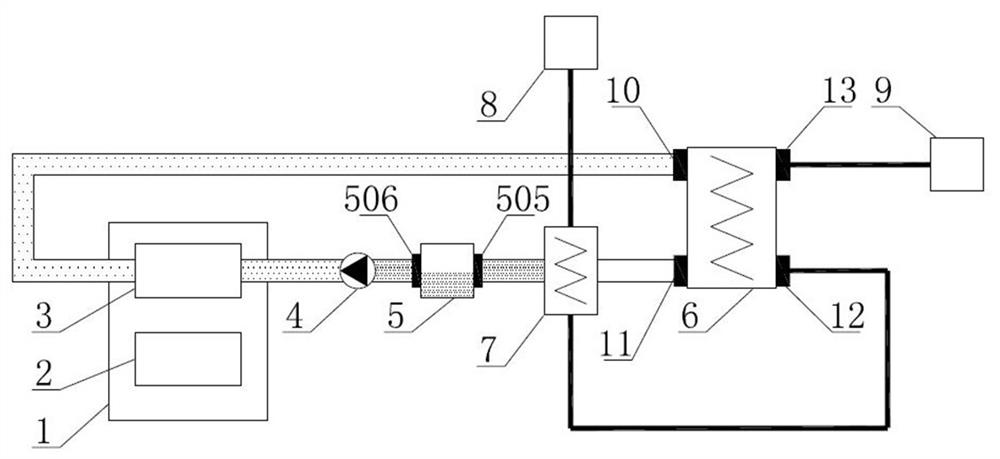

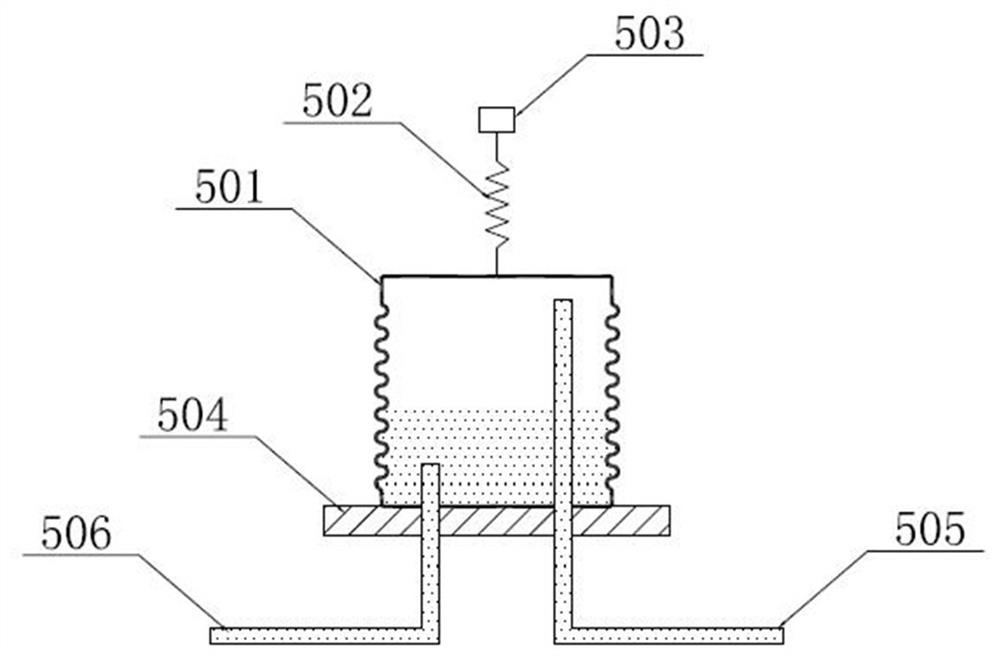

[0014] Such as figure 1 As shown, 1 in the figure is a solid heat storage unit, 2 is an electric heating unit, 3 is a heat source heat exchange unit, and 4 is a booster water pump; the electric heating unit 2 and heat source heat exchange unit 3 are arranged in a Inside the solid heat storage unit 1 of the body, the heat outlet end of the heat source heat exchange unit is connected to the heat exchange inlet 10 of the user heat exchanger unit 6 through a hot water pipe, and the hot water after heat exchange by the user heat exchanger unit 6 The pipe is connected with the inlet end of the heat source heat exchange unit 3 as the return pipe 11, and the constant pressure control unit 5 and the booster water pump 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com