Fuel cell hydrogen supply and return system and fuel cell

A fuel cell and hydrogen system technology, applied in the direction of fuel cells, fuel cell additives, circuits, etc., can solve the problems of cumbersome fixing of pipelines and parts, unreasonable component layout, and high water content in hydrogen, so as to improve the use of hydrogen Economy and reliability, reduce the risk of flooding, achieve the effect of water vapor separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

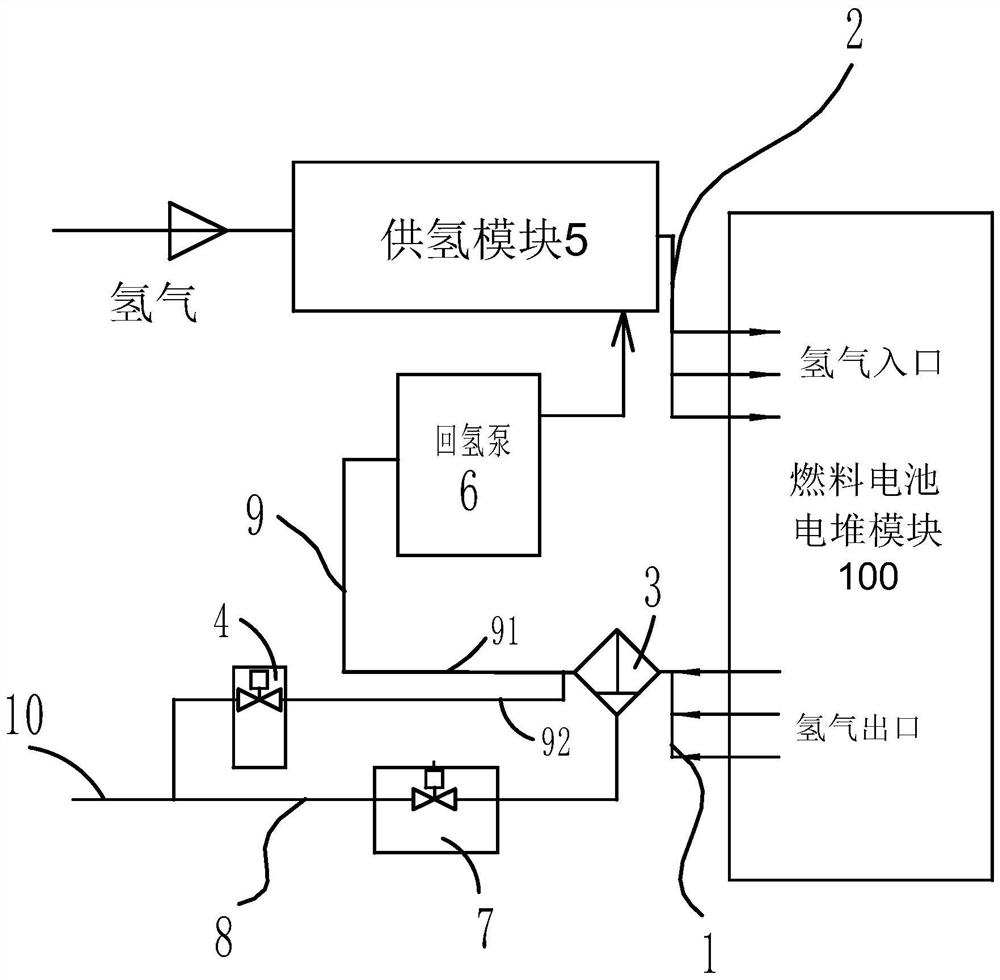

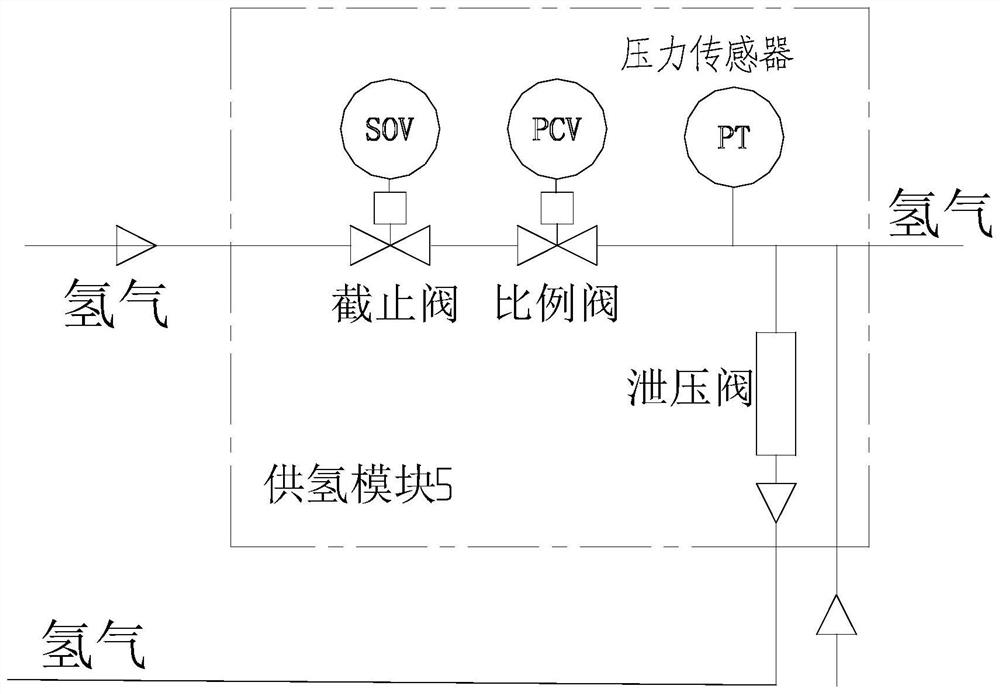

[0031] Such as Figure 1 to Figure 7 As shown, this embodiment provides a fuel cell hydrogen supply and hydrogen return system, including stack hydrogen outlet pipe 1, stack hydrogen inlet pipe 2, water vapor separator 3, and purge valve distributed around the stack module 100 4. The hydrogen supply module 5 and the hydrogen return pump 6 (also known as the hydrogen circulation pump), the high-pressure hydrogen enters the hydrogen inlet of the stack module 100 through the hydrogen supply module 5 and the stack hydrogen inlet pipe 2, and the hydrogen gas outlet of the stack module 100 It is connected with the hydrogen gas outlet pipe 1 of the stack, and the hydrogen gas outlet of the stack module 100 flows the mixed gas containing hydrogen through the hydrogen gas outlet pipe 1 of the stack into the water vapor separator 3 for primary water vapor separation, and the water separated by the water vapor separator 3 passes through The pipeline 8 with the drain valve 7 is discharged...

Embodiment 2

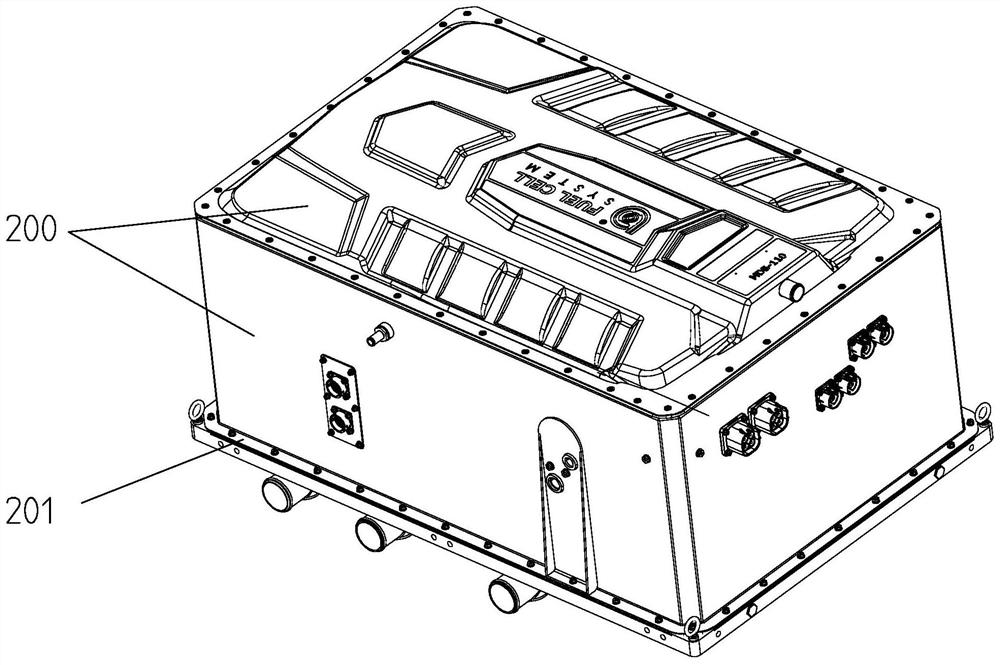

[0044] Such as Figure 8 As shown, a fuel cell includes a stack module 100, a hydrogen supply and return system, a cooling system, and an air supply system, wherein the hydrogen supply and return system adopts the fuel cell hydrogen supply and return system described in Embodiment 1 . It has a compact structure and small volume, which can effectively separate water and vapor, reduce the risk of flooding of the system stack, discharge waste water and waste gas separately, and improve the hydrogen economy and reliability of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com