Method for preparing high-humidity extruded protein meat from soybean protein concentrate and carboxymethyl cellulose

A technology of soybean protein concentrate and carboxymethyl cellulose, which is applied in protein food processing, vegetable protein processing, protein food ingredients, etc., can solve problems such as insufficient taste of high-humidity extruded protein meat, and achieve high similarity and comprehensive nutrition. , taste firming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

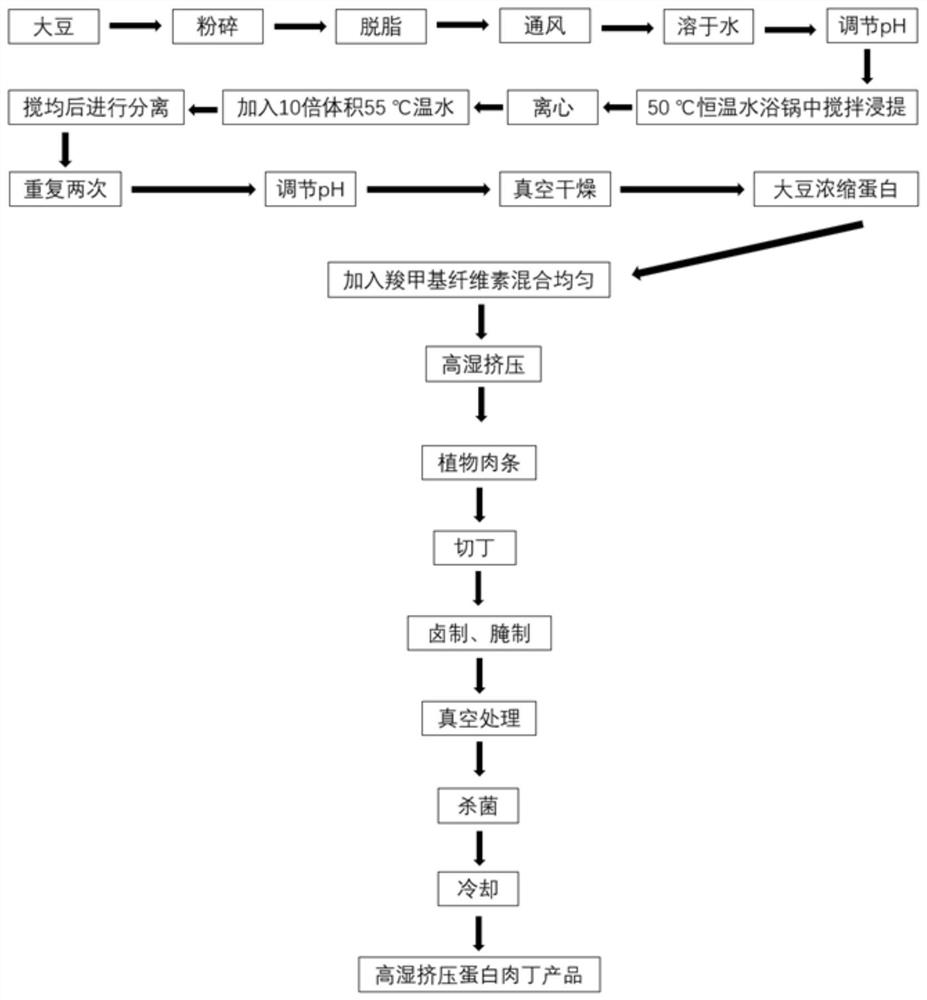

Image

Examples

specific Embodiment approach 1

[0021] Step 1. Grinding soybeans, degreasing the crushed soybean powder with n-hexane at a ratio of 1:3 (w / v) three times, and removing n-hexane in a fume hood. Mix the defatted soy flour from which n-hexane has been removed with water at a ratio of 1:10 (w / w), adjust the pH value to about 4.5, stir and extract in a constant temperature water bath at 50°C for 60 minutes, and centrifuge at 4 000 r / min for 10 minutes. Add 10 times the volume of warm water at 55°C to the mixture, stir evenly and separate, repeat twice to increase the yield of soybean protein. Dissolving the curd and adjusting the pH value to 6.5, drying in a vacuum environment to obtain powdered soy protein concentrate;

[0022] Step 2: Add carboxymethyl cellulose to soybean protein concentrate for preparation and mix evenly, wherein the preferred mass ratio of soybean protein concentrate and carboxymethyl cellulose is: 1:0.03.

[0023] Step 3: Perform high-humidity extrusion on the uniformly mixed materials to ...

specific Embodiment approach 2

[0024] Step 1. Grinding soybeans, degreasing the crushed soybean powder with n-hexane at a ratio of 1:3 (w / v) three times, and removing n-hexane in a fume hood. Mix the defatted soy flour from which n-hexane has been removed with water at a ratio of 1:10 (w / w), adjust the pH value to about 4.5, stir and extract in a constant temperature water bath at 50°C for 60 minutes, and centrifuge at 4 000 r / min for 10 minutes. Add 10 times the volume of warm water at 55°C to the mixture, stir evenly and separate, repeat twice to increase the yield of soybean protein. Dissolving the curd and adjusting the pH value to 6.5, drying in a vacuum environment to obtain powdered soy protein concentrate;

[0025] Step 2: Add carboxymethyl cellulose to soybean protein concentrate for preparation and mix evenly, wherein the preferred mass ratio of soybean protein concentrate and carboxymethyl cellulose is 1:0.06.

[0026] Step 3: Perform high-humidity extrusion on the uniformly mixed materials to o...

specific Embodiment approach 3

[0027] Step 1. Grinding soybeans, degreasing the crushed soybean powder with n-hexane at a ratio of 1:3 (w / v) three times, and removing n-hexane in a fume hood. Mix the defatted soy flour from which n-hexane has been removed with water at a ratio of 1:10 (w / w), adjust the pH value to about 4.5, stir and extract in a constant temperature water bath at 50°C for 60 minutes, and centrifuge at 4 000 r / min for 10 minutes. Add 10 times the volume of warm water at 55°C to the mixture, stir evenly and separate, repeat twice to increase the yield of soybean protein. Dissolving the curd and adjusting the pH value to 6.5, drying in a vacuum environment to obtain powdered soy protein concentrate;

[0028] Step 2: Add carboxymethyl cellulose to soybean protein concentrate for preparation and mix evenly, wherein the preferred mass ratio of soybean protein concentrate and carboxymethyl cellulose is: 1:0.09.

[0029] Step 3: Perform high-humidity extrusion on the uniformly mixed materials to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com