Automatic material connection system and connection method

A material and material box technology, which is applied in the direction of motor vehicles, object destacking, object stacking, etc., can solve the problems of affecting the production efficiency of industrial production enterprises, affecting the normal production of industrial production enterprises, and insufficient positioning accuracy of AGV trolleys. Achieve the effect of improving material turnover efficiency, high use and promotion value, and simple and fast docking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention provides an automatic material connection system and connection method used in industrial production process, the details are as follows.

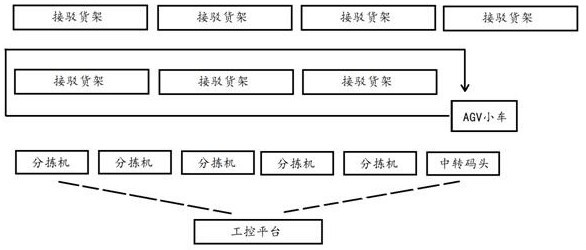

[0037] like figure 1 As shown, an automated material connection system covers the sorting area, transfer area and shelf area in an industrial production enterprise, including:

[0038] There are multiple sorting machines, which are set in the sorting area, and are used to sort the materials and put the materials one by one into the material boxes set on it;

[0039] The transfer terminal is set in the transfer area and is used to place empty material boxes for retrieval;

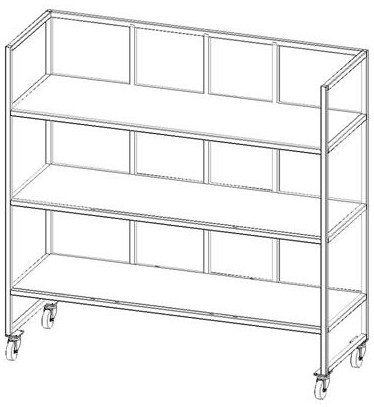

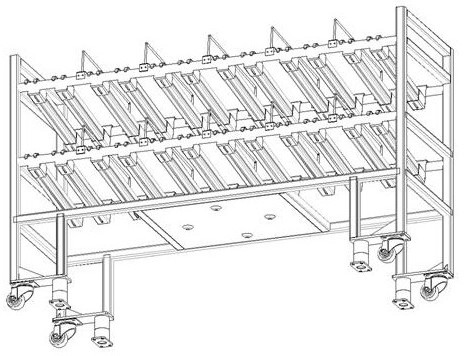

[0040] There are multiple connecting shelves, which are movably arranged in the shelf area, and are used to place material boxes full of materials;

[0041] AGV (Automated Guided Vehicle) trolleys, equipped with multiple sets, move freely between the sorting area, the transfer area and the shelf area, and are used to send the empty material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com