Polycarbonate/polyester alloy composition resistant to long-term thermo-oxidative aging and preparation method thereof

A polycarbonate and polyester alloy technology, applied in the field of engineering plastics, can solve the problems of surface cracking, molecular chain reduction, material mechanical properties decline, etc., to improve long-term thermal and oxygen aging resistance, easy to mass production, preparation simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 17

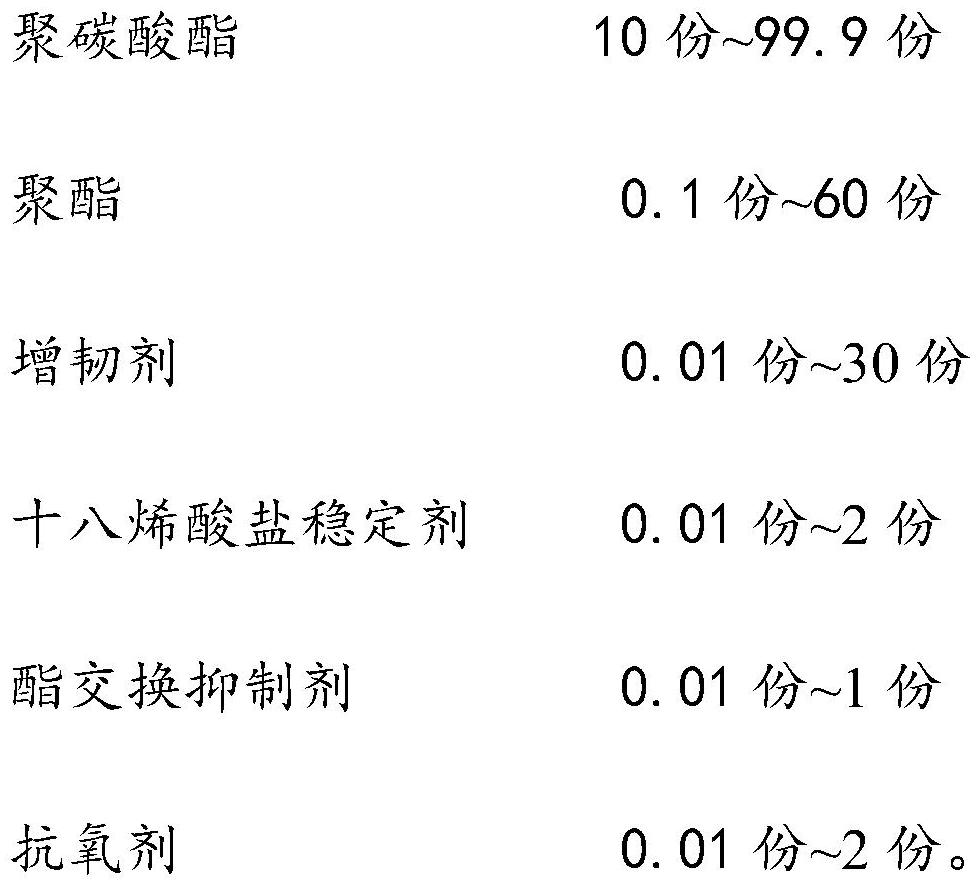

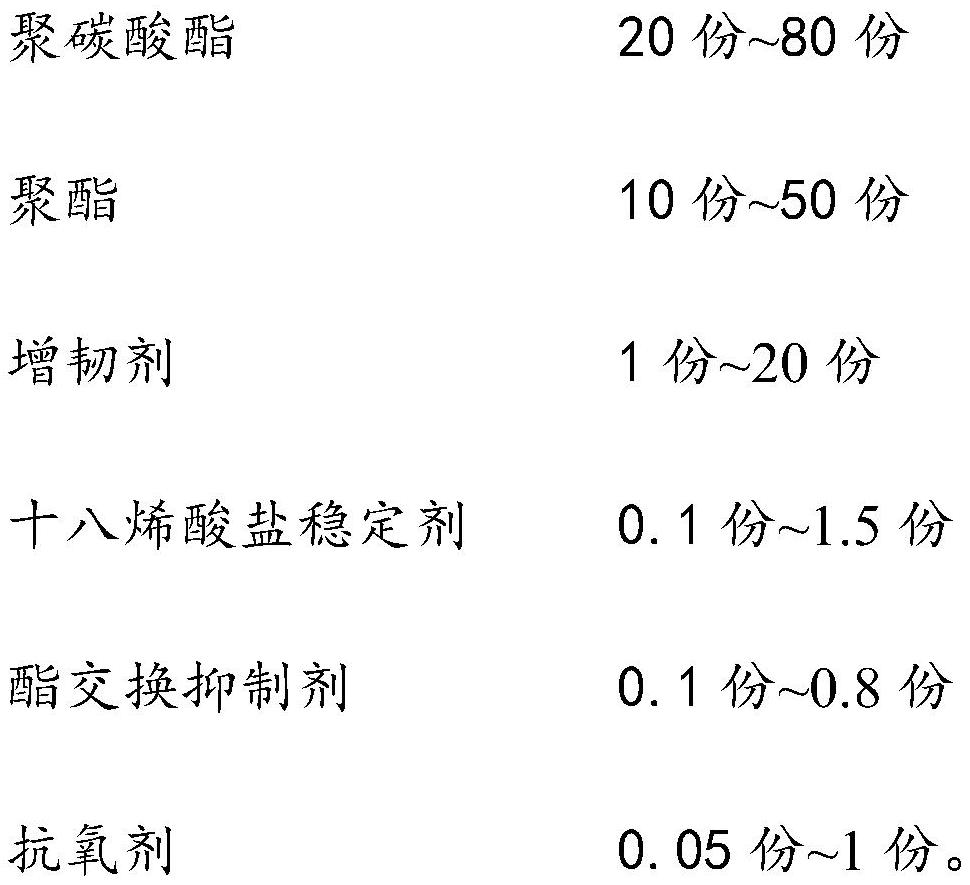

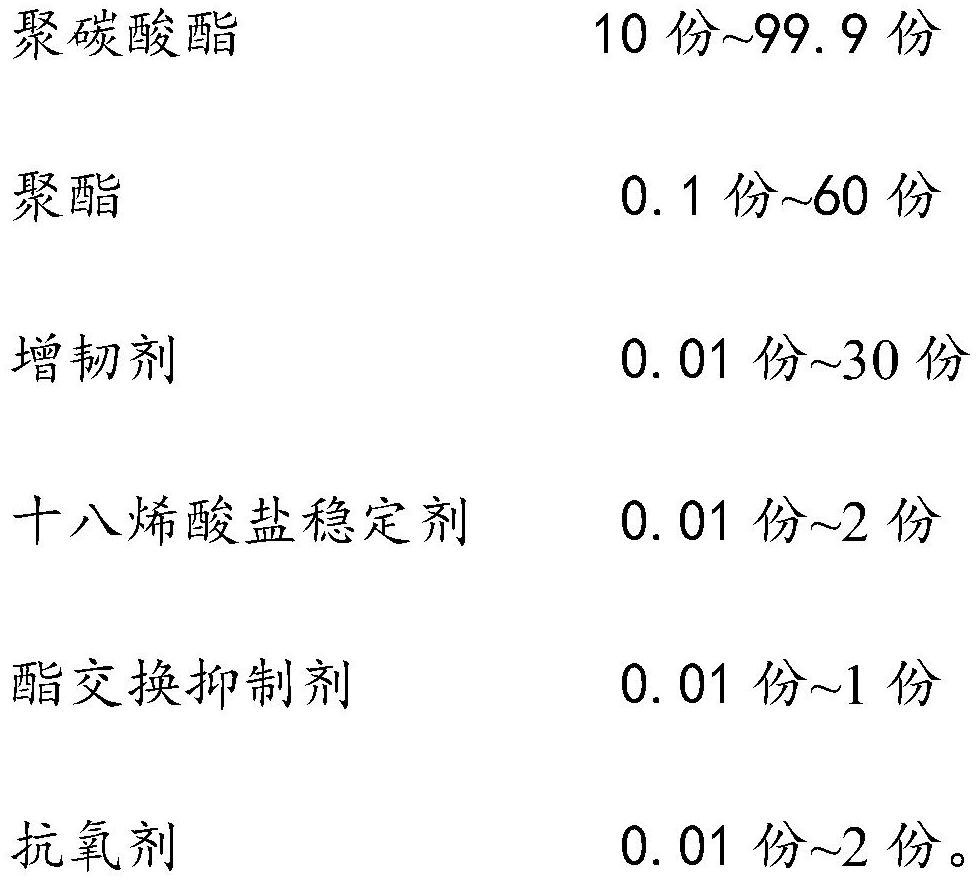

[0059] The polycarbonate / polyester alloy compositions resistant to long-term thermal and oxidative aging of each embodiment were prepared by the following raw material formulations (see Table 1) and methods.

[0060] According to the raw material formula in Table 1, polycarbonate, polyester, acrylic-silicone rubber toughener, octadecylenate stabilizer, transesterification inhibitor, antioxidant and lubricant were stirred in a mixer Mix to obtain a premix; put the above premix into a twin-screw extruder, melt and mix in the twin-screw extruder, extrude and granulate, and obtain a polycarbonate / polyester alloy combination resistant to long-term thermal oxygen aging things. Among them, the screw aspect ratio of the twin-screw extruder is 40-45:1, the temperature of the screw barrel is 210-250° C., and the screw speed is 500-600 rpm.

[0061] Table 1 Embodiment 1~7 each component distribution ratio (by weight) and performance test result thereof

[0062]

[0063]

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com