Displacement detection device, washing machine and control method of washing machine

A displacement detection and control method technology, applied in the control device of washing machine, washing device, textile and papermaking, etc., can solve the problems of abnormal displacement, the outer barrel hitting the box, and the mechanical barrel hitting switch failure, etc., to improve the use experience, The effect of reducing vibration noise and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

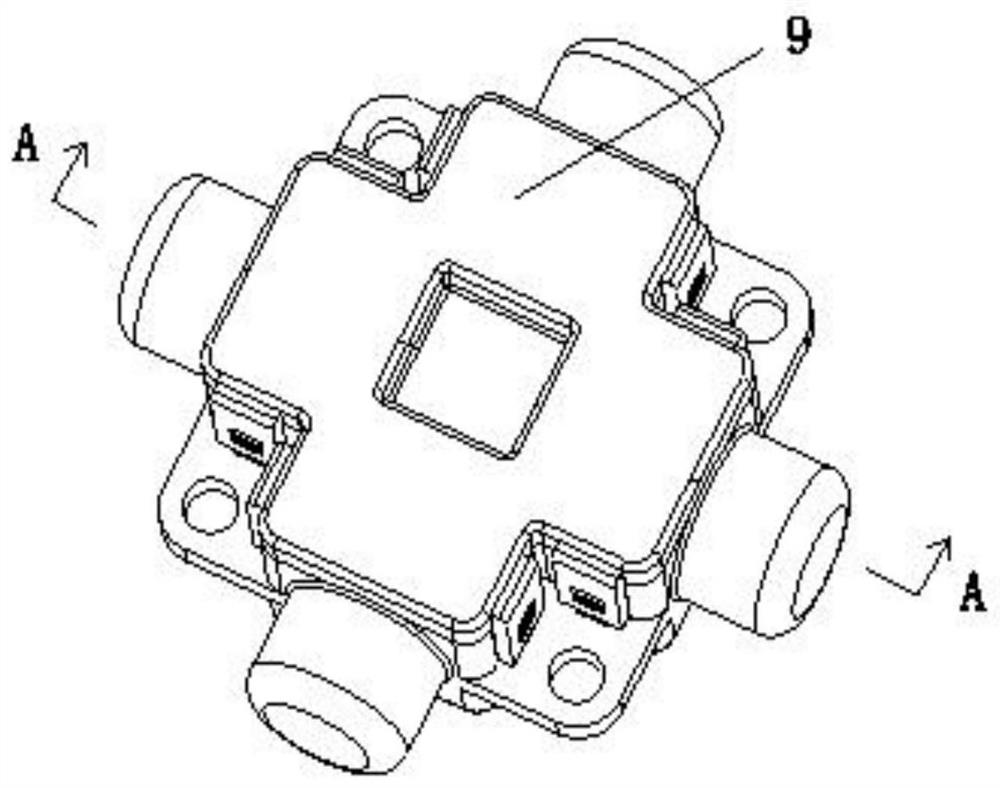

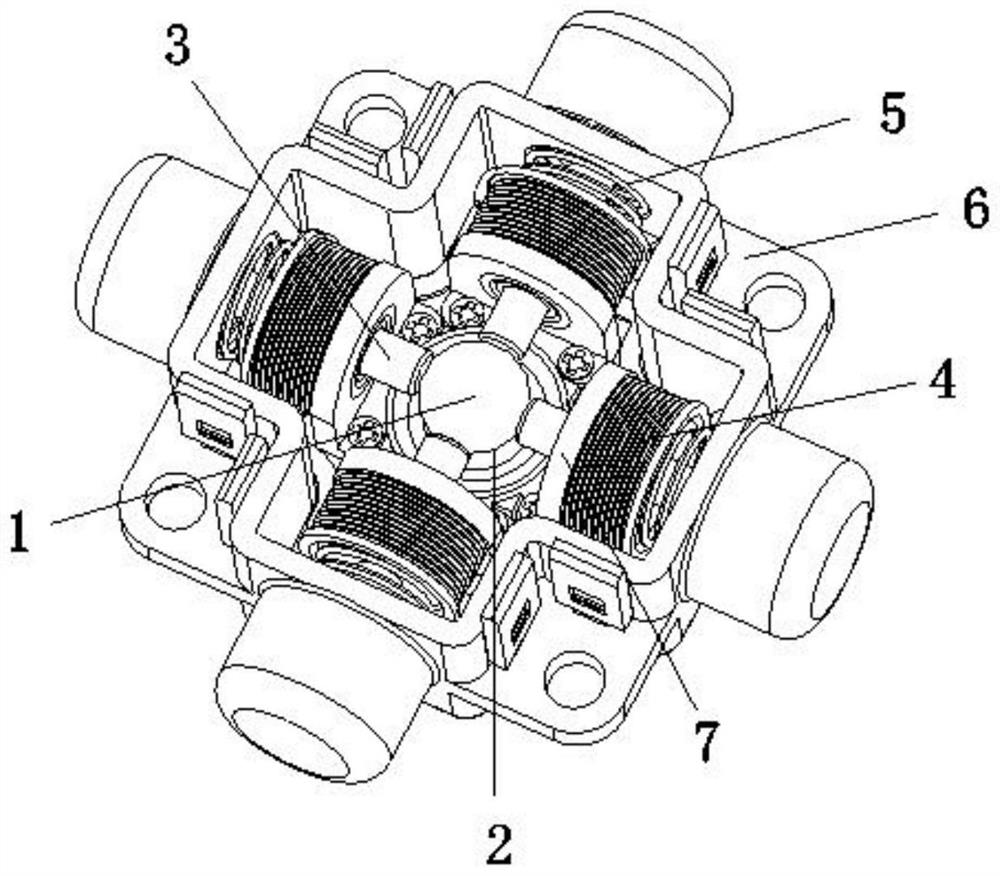

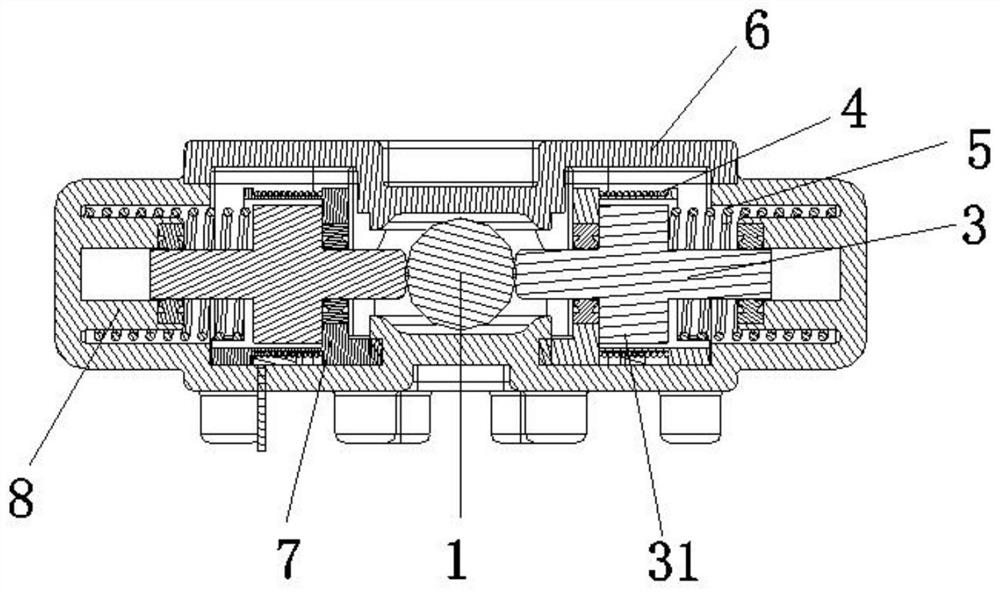

[0043] Such as Figure 1-Figure 4As shown, this embodiment discloses a displacement detection device 9, the displacement detection device 9 includes a vibration element 1 and a plurality of displacement detection units, one end of the plurality of displacement detection units encloses a housing space 2, and the vibration element 1 Arranged in the accommodating space 2, the vibrating element 1 can move in the accommodating space 2 to trigger a corresponding displacement detection unit to generate a detection signal.

[0044] Wherein, each of the displacement detection units includes a touch piece and a measuring piece connected to the touch piece, and the touch piece of a plurality of the displacement detection units encloses an accommodating space 2, and the vibrating element 1 is arranged in the accommodating space 2 Inside, and the vibrating element 1 can move between the touch pieces of each displacement detection unit to trigger the corresponding measurement piece to gener...

Embodiment 2

[0053] The present invention also discloses a washing machine, including the displacement detection device 9 described in Embodiment 1, the displacement detection device 9 is electrically connected to the controller of the washing machine, preferably, the washing machine includes a box body and The outer barrel arranged in the box, the outer barrel is provided with a displacement detection device 9 as described in Embodiment 1, and the displacement detection device 9 is installed on the outer barrel, which can be installed on the bottom of the outer barrel, the side wall and the outer barrel The upper part is preferably installed on the bottom of the outer tub, and of course it can also be installed on the washing machine cabinet, which is not specifically limited here.

[0054] When the washing machine is working, if the washing machine does not vibrate, the vibrating element 1 can only stop quietly in the accommodation space 2 without shaking in any direction. However, in mos...

Embodiment 3

[0058] Such as Figure 1-5 As shown, the present invention also discloses a control method using the washing machine as described above. The control method includes that during the dehydration process of the washing machine, the displacement detection device 9 generates inductance values in multiple directions through the shaking of the outer tub. The controller controls the dehydration process of the washing machine according to the changes in inductance in multiple directions generated by the displacement detection device 9 .

[0059] Further, when the changes in the inductance of the displacement detection device 9 in multiple directions acquired by the controller are all within the range of the preset inductance, the washing machine is controlled to continue the dehydration process;

[0060] Preferably, controlling the washing machine to continue to perform the dehydration process includes: controlling the motor of the washing machine to adjust the current speed a to a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com