Underground pipeline inner wall hot melting repair complete equipment and method

A complete set of equipment and underground pipeline technology, which is applied in the direction of mechanical equipment, pipe components, special pipes, etc., can solve the problems that the inner lining layer and the inner wall of the original pipeline are not tightly bonded, the inner lining layer is easy to detach and collapse, and the quality of pipeline repair is affected. , to achieve the effect of reducing unstable factors, reducing the amount of construction and excavation, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

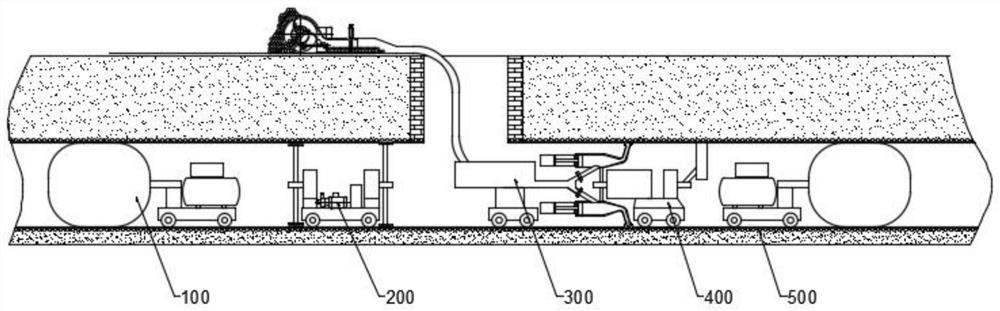

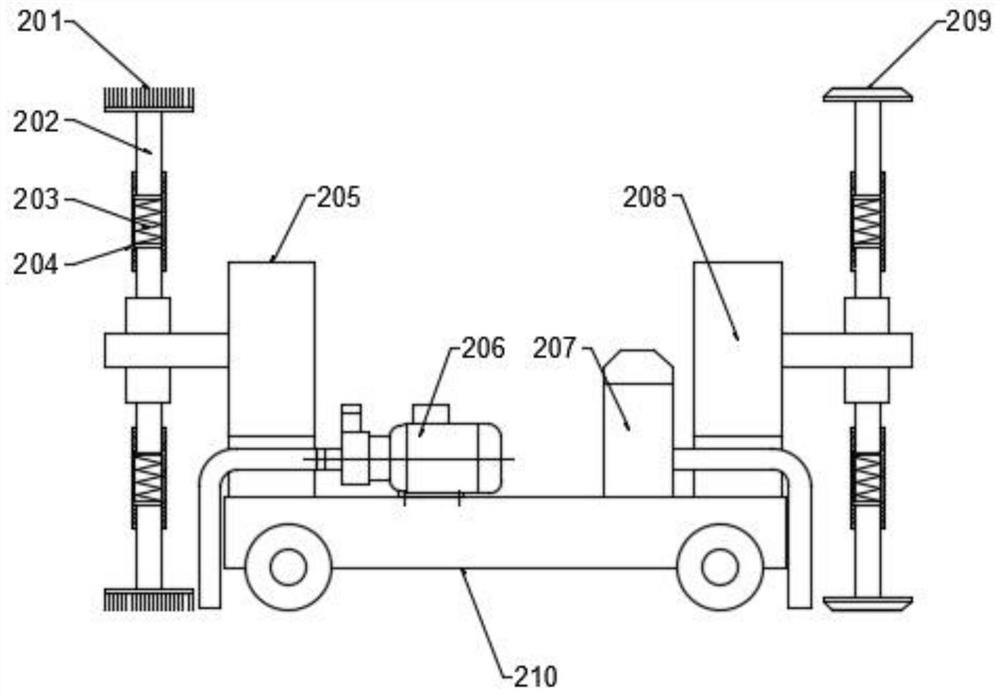

[0039] Such as Figure 1-7 As shown, this embodiment provides a complete set of equipment for hot-melt repair of the inner wall of an underground pipeline, including a sealing device 100 for sealing both ends of the pipeline repair section, and a cleaning device 200 for cleaning the pipeline repair section , a conveying device 300 for conveying plastic pellets and a melt extrusion molding device 400, the discharge end of the conveying device communicates with the feed end of the melt extrusion molding device.

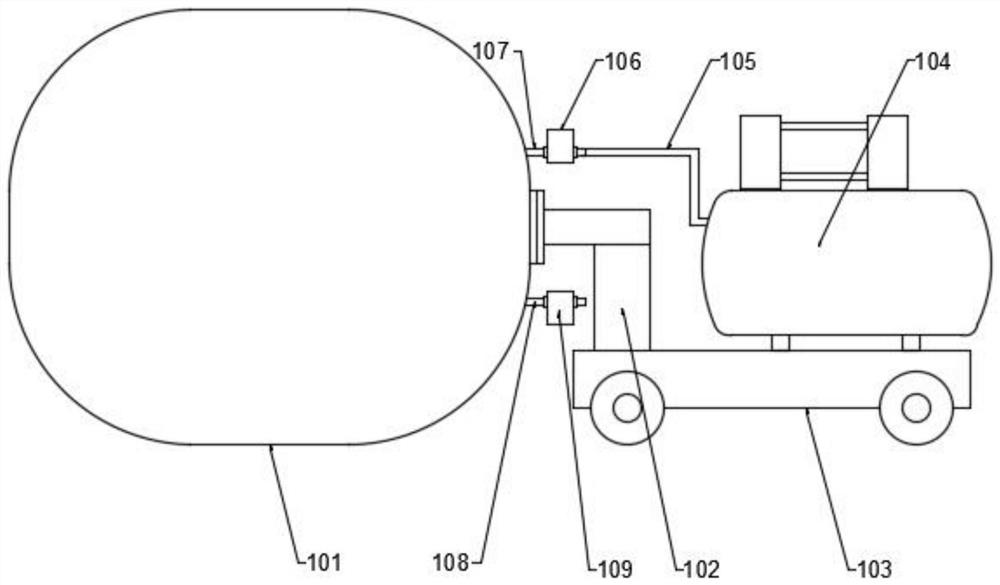

[0040] The blocking device comprises an airbag 101, an airbag bracket 102, an air pump 104 and a blocking trolley 103, the airbag is fixed on the blocking trolley through the airbag bracket, and an air inlet nozzle 107 and an exhaust nozzle 108 are arranged on the airbag. The intake nozzle and the exhaust nozzle are respectively provided with an intake valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com