Vehicle battery fast charging heat management system based on L-shaped pulsating heat pipe and temperature control method

A pulsating heat pipe and management system technology, applied in the field of new energy vehicle battery thermal management system, can solve the problems that the battery fast charging technology cannot be fully developed and the battery charging problem cannot be properly solved, so as to reduce the fast charging time and enhance the fast charging The effect of capacity, voltage and current increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

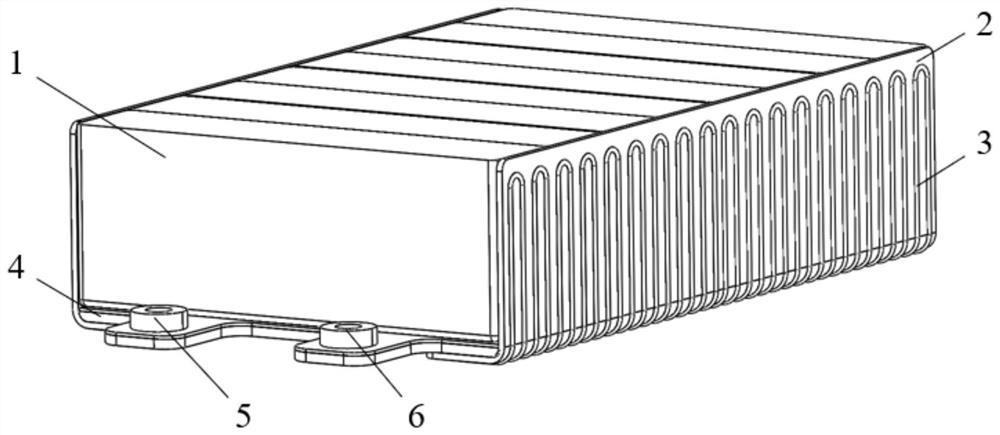

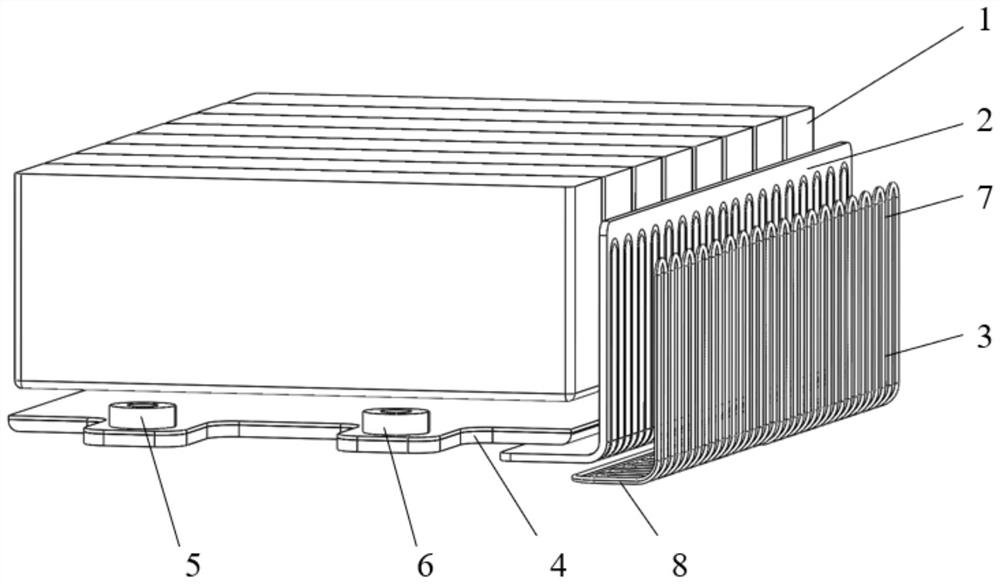

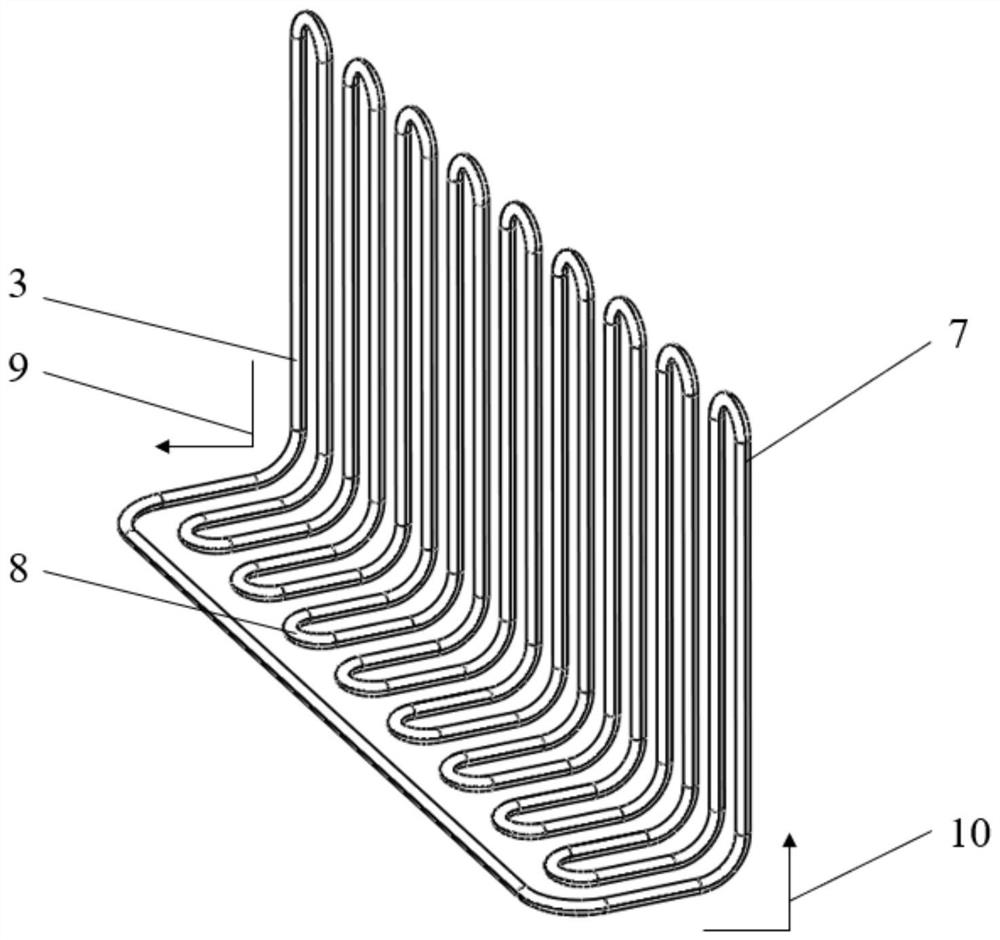

[0035] The embodiment of the present invention discloses a thermal management system mainly applied to fast charging of vehicle batteries, which combines a pulsating heat pipe and a liquid cooling system. It mainly corresponds to the large amount of heat brought by the rapid charging of the current vehicle battery, which causes the battery temperature to rise sharply, and the liquid-cooled battery thermal management system cannot perfectly solve this problem. safety and other issues. The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0036] The present invention utilizes the cooperation of the L-shaped pulsating heat pipe with the battery module and the liquid cooling system. The vertical end of the L-shaped pulsating heat pipe is in contact with the side of the battery module through the contact key, and the horizontal end is in contact with the water-cooled plate to fully utiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com