Groove for longitudinal and circular seams of large-diameter vessel and welding method

A large-diameter and groove technology is applied in the groove and welding fields for longitudinal and circumferential seams of large-diameter containers. It can solve the problems of penetrating cracks, affecting product production, shell cracks, etc. The effect of reducing stress corrosion cracking and reducing weld deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

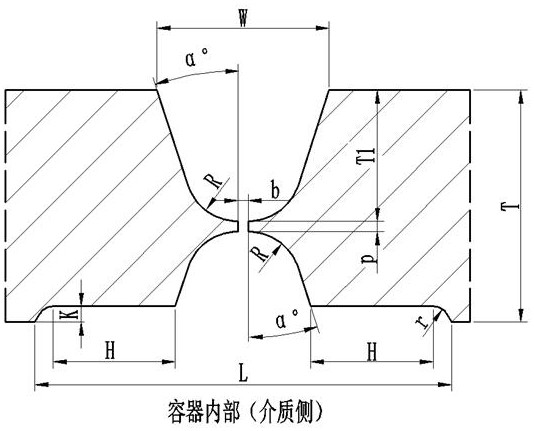

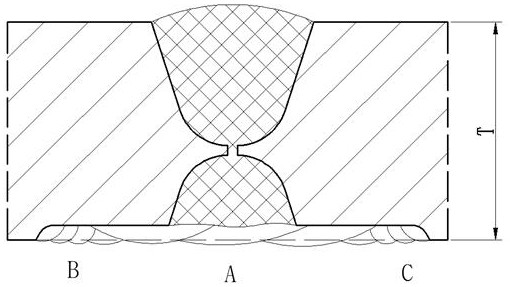

[0025] A groove used for the longitudinal and circular seams of large-diameter containers. The groove is a double-sided U-shaped groove, which is welded on the inner and outer sides of the container. There is a groove gap between the U-shaped grooves on both sides. Processing grooves inside the container cylinder and surfacing welding in the grooves;

[0026] The U-shaped groove has unequal thickness structures on both sides, and the depth of one side of the deep U-shaped groove is 0.6-0.7 times the wall thickness of the container.

Embodiment 2

[0028] According to the bevel used for the longitudinal and annular seams of large-diameter containers described in Embodiment 1, the depth of the groove is 3-3.5mm.

Embodiment 3

[0030] According to the bevel used for the longitudinal and annular seams of large-diameter containers described in embodiment 1 or 2, there is a bevel gap of 4-5 mm between the U-shaped bevels on both sides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com