Technical method for preventing adhesion of cushion pad

A cushioning pad and anti-adhesion technology, which is applied to the unpacking of objects, the removal of binding materials, and packaging. It can solve the problems of inability to guarantee the complete separation of the extraction and separation points, the sticking of the copper clad laminate, and the impact on the yield, so as to reduce the adhesion. The probability of walking, the improvement of yield rate, and the effect of good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

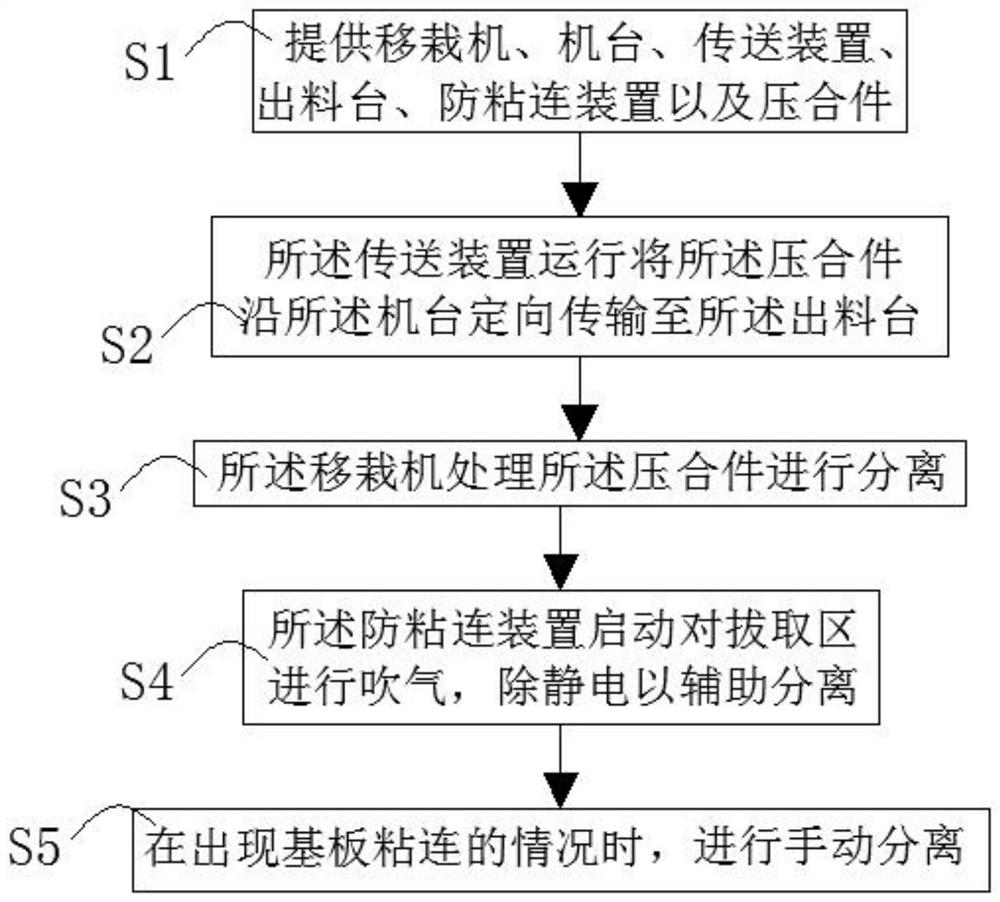

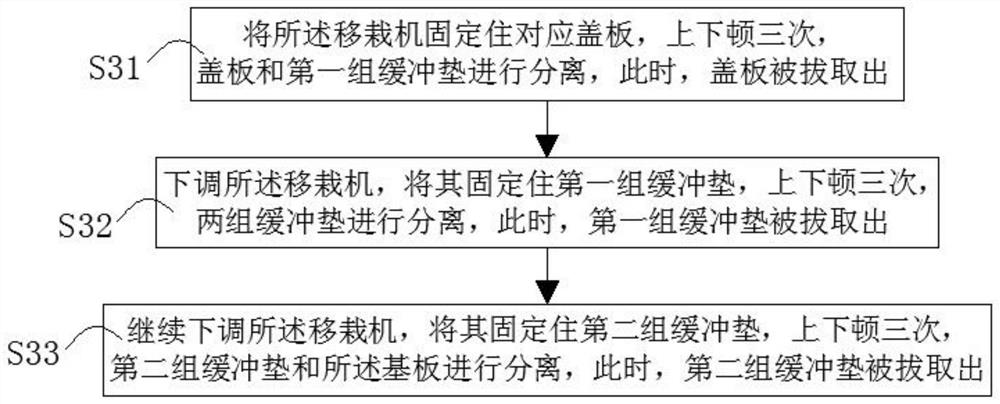

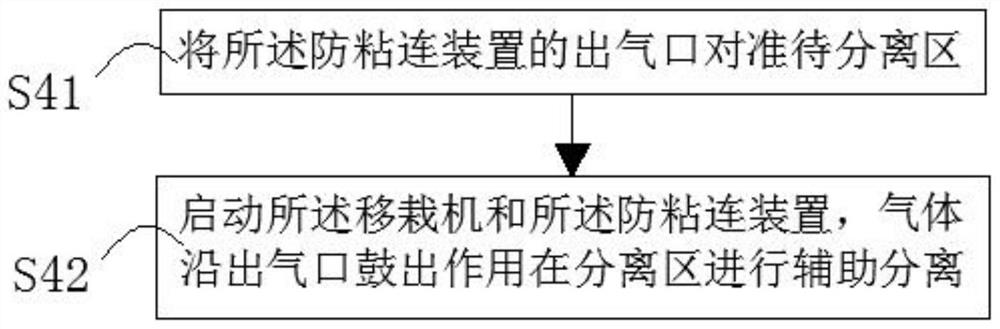

[0044] see figure 1 , this embodiment provides a technical method for preventing the adhesion of the buffer pad, which is used to provide anti-adhesion protection when the copper clad laminate is processed. The method comprises the steps of:

[0045] S1 provides transplanting machines, machine tables, conveying devices, discharge tables, anti-adhesion devices and pressing parts.

[0046] The number of the anti-adhesion devices is four groups, and the four groups of the anti-adhesion devices are evenly distributed around the discharge table.

[0047] The pressing part is obtained by pressing the base plate, buffer pad and cover plate. Wherein, the cover plate is located above the base plate, and twenty sets of base plates and four sets of buffer pads are neatly stacked vertically. Two sets of buffer pads are located between the machine table and the base plate, and the remaining two sets of buffer pads are located between the base plate and the cover plate.

[0048] S2 plac...

Embodiment 2

[0065] see Figure 4 , this embodiment provides an anti-adhesion device, which is applied in the technical method for preventing the adhesion of the cushion pad as described in Embodiment 1. The anti-adhesion device includes an air blowing structure 1 , a positioning assembly 2 arranged on the air blowing structure 1 , a fixing assembly 3 and an air source (not shown in the figure).

[0066] The gas source is used to provide clean gas. The blowing structure 1 is used for blowing the extraction area. The air blowing structure 1 includes an air pipe 11 and an air nozzle 12 fixedly installed at one end of the air pipe 11 . One end of the air pipe 11 facing away from the air nozzle 12 is fixedly connected with the air source. The positioning assembly 2 includes a guide post 21 fixedly sleeved on the outer surface of the trachea 11 , and a bushing 22 compatible with the guide post 21 . The guide post 21 is screwed inside the bushing 22 . The fixing component 3 is used to insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com