An auxiliary product used in spandex spinning oil to isolate and adjust friction

A technology of spinning oil and friction, which is applied in the field of functional silicone materials, can solve the problems of wasting spandex yarn, messy yarn, and low fiber friction, and achieve storage stability, long-term compatibility, and increased cohesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

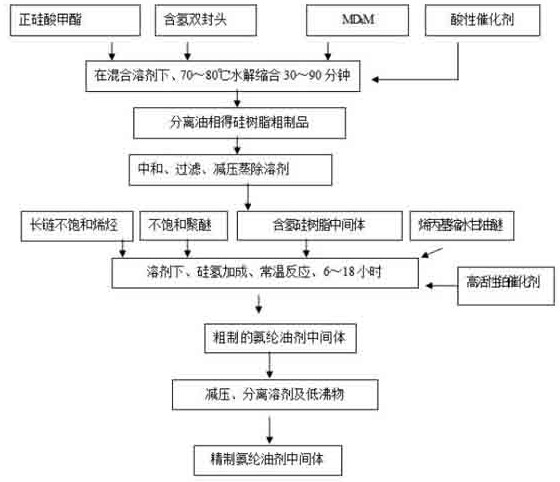

Method used

Image

Examples

Embodiment 1

[0027] Weigh 35mg methyl orthosilicate, 10mg water, 9mg ethanol, 8mg toluene, 8.5mg dimethylsiloxane tetramer, 4mg tetramethyldihydrodisiloxane and 220mg hydrochloric acid with a mass fraction of 1%. ;

[0028] Mix and dissolve water, ethanol and toluene to prepare a mixed solvent, then dissolve silicate ester, dimethylsiloxane tetramer and hydrogen-containing double head in the mixed solvent, and then dropwise add hydrochloric acid as a catalyst at 70 ℃ hydrolysis and condensation for 50min to synthesize silicone resin base material;

[0029] Filter the oil phase in the mixed solution containing the silicone resin base material obtained in step 1 to obtain a crude silicone resin product, and the crude product is sequentially added dropwise with a sodium hydroxide solution with a mass fraction of 1% to neutralize to neutrality, and then filtered again, The obtained solid was washed three times with distilled water, 5ml each time, and then the solid was placed in an oven, the ...

Embodiment 2

[0033] Weigh 42 mg of methyl orthosilicate, 13 mg of water, 11 mg of propanol, 10 mg of ethylbenzene, 9.2 mg of dimethylsiloxane tetramer, 7 mg of tetramethyldihydrodisiloxane and 280 mg of 1% Hydrochloric acid for use;

[0034] Mix and dissolve water, propanol and ethylbenzene to prepare a mixed solvent, then dissolve silicate, dimethylsiloxane tetramer and hydrogen-containing double-head in the mixed solvent, and then add hydrochloric acid dropwise as a catalyst in the mixed solvent. 80℃ hydrolysis and condensation for 90min to synthesize silicone resin base material;

[0035] The oil phase in the mixed solution containing the silicone resin base material obtained in the first step is filtered to obtain a crude silicone resin product, and the crude product is sequentially neutralized to neutrality through a sodium hydroxide solution with a mass fraction of 1%, and then filtered again, and the The obtained solid was washed three times with distilled water, 5ml each time, and...

Embodiment 3

[0039] Weigh 37mg methyl orthosilicate, 11mg water, 10mg ethanol, 9mg p-xylene, 8.6mg dimethylsiloxane tetramer, 4.5mg tetramethyldihydrodisiloxane and 230mg mass fraction of 1% of hydrochloric acid for use;

[0040] Mix and dissolve water, ethanol and p-xylene to prepare a mixed solvent, then dissolve the silicate ester, dimethylsiloxane tetramer and hydrogen-containing double head in the mixed solvent, and then add hydrochloric acid dropwise as a catalyst Synthesize silicone resin base material by hydrolysis and condensation at 72℃ for 45min;

[0041]The oil phase in the mixed solution containing the silicone resin base material obtained in the first step is filtered to obtain a crude silicone resin product. The obtained solid was washed three times with distilled water, 5ml each time, then the solid was placed in an oven, the pressure was adjusted to 1.5Mpa, and the temperature was adjusted to 150°C for pressure distillation, and the silicone resin base material was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com