Hydraulic full-time floating control system and control method of boom type aerial work platform

An aerial work platform and hydraulic system technology, applied in the field of construction machinery, can solve the problems of increasing engine power loss, hydraulic system power loss, heat generation, power loss, energy consumption loss, etc., and solve valve stem offset wear and low control accuracy. , improve the control accuracy and system reliability, improve the effect of operating comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

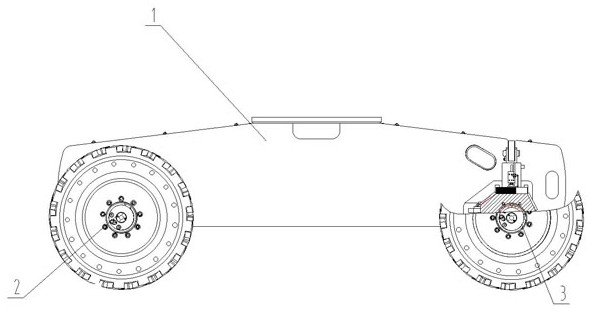

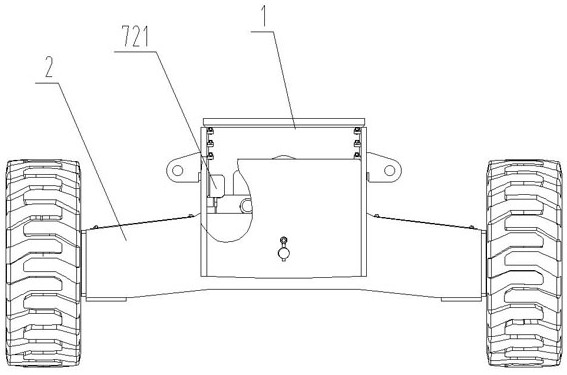

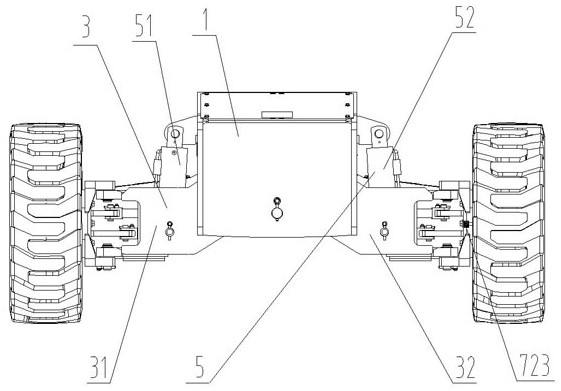

[0051] Such as figure 1 , 2 , 3, 4 and 5, a hydraulic full-time floating control system for boom-type aerial work platforms, including chassis 1, integral swing bridge assembly 2, split floating bridge assembly 3 and complete machine hydraulic system 4 , the integral swing bridge assembly 2 and the split floating bridge assembly 3 are respectively hinged with the chassis 1, the integral swing bridge assembly 2 can swing left and right relative to the central symmetry plane of the chassis 1, and the split floating bridge assembly The component 3 includes a left floating end 31 and a right floating end 32, the left floating end 31 and the right floating end 32 can swing around the hinge shaft respectively; the complete machine hydraulic system 4 includes a hydraulic pump assembly 41 , the main control valve 42 and the hydraulic actuator 43, the hydraulic pump assembly 41 supplies oil to the hydraulic actuator 43 through the main control valve 42; it is characterized in that:

...

Embodiment 2

[0074] Such as figure 1 , 2 , 3, 6 and 7, a hydraulic full-time floating control system for boom-type aerial work platforms, including chassis 1, integral swing bridge assembly 2, split floating bridge assembly 3 and complete machine hydraulic system 4 , the integral swing bridge assembly 2 and the split floating bridge assembly 3 are respectively hinged with the chassis 1, the integral swing bridge assembly 2 can swing left and right relative to the central symmetry plane of the chassis 1, and the split floating bridge assembly The component 3 includes a left floating end 31 and a right floating end 32, the left floating end 31 and the right floating end 32 can swing around the hinge shaft respectively; the complete machine hydraulic system 4 includes a hydraulic pump assembly 41 , the main control valve 42 and the hydraulic actuator 43, the hydraulic pump assembly 41 supplies oil to the hydraulic actuator 43 through the main control valve 42; it is characterized in that:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com