Manufacturing method of low-gap high-vanadium-titanium alloy for sports equipment

A high-vanadium titanium alloy and sports equipment technology, applied in the direction of temperature control, etc., can solve the problems that the quality of high-β-type titanium alloy cannot reach the level of developed countries, the composition is difficult to control, and the performance gap is large, so as to achieve good heat treatment strengthening performance, good Cold and hot processing performance, satisfying the effect of high strength and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

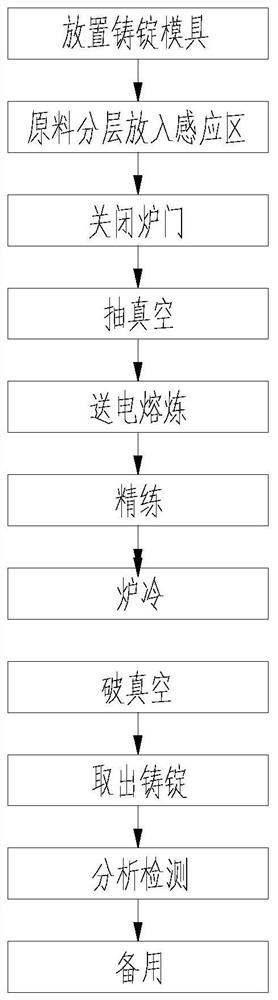

[0036] Please refer to the attached figure 1 , the titanium alloy master alloy is smelted by ingot casting in the following order:

[0037] Step 1. Put the self-made vanadium furnace master alloy produced by the thermite method, super-0-grade sponge titanium, self-made titanium-tin alloy, and pure zirconium into the induction zone of the water-cooled copper crucible vacuum induction furnace, and then close the furnace door ;

[0038] Step 2, extracting the air in the water-cooled copper crucible vacuum induction furnace;

[0039] Step 3, start the power supply of the water-cooled copper crucible vacuum induction furnace, refine after melting in the water-cooled copper crucible vacuum induction furnace;

[0040] Step 4. Input the raw materials refined in Step 3 into the ingot mold to complete the ingot casting;

[0041] Step 5. After the belt furnace is cooled, break the vacuum;

[0042] Step 6: Take out the produced titanium alloy master alloy ingot, and store it for futur...

Embodiment 2

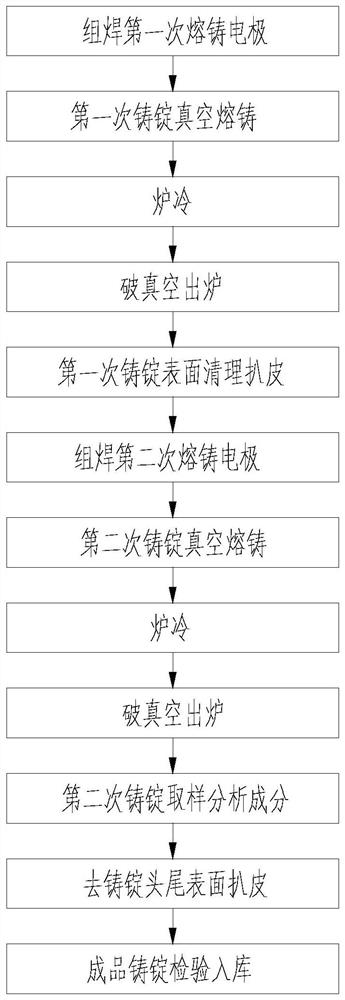

[0045] Please refer to the attached figure 2 , attached image 3 , the low-gap high-vanadium titanium alloy is produced by the steps in the following order:

[0046] Step 1. In a self-made vacuum welding box, the titanium alloy master alloy ingot and the TA0 bar of ultra-low interstitial elements are uniformly distributed in the axial and radial directions;

[0047] Step 2, using the plasma welding method to assemble and weld the vacuum consumable electrode of the primary ingot;

[0048] Step 3: Fix the welded self-consumable electrode on the vacuum consumable furnace, and carry out the first vacuum consumable ingot melting and casting according to the established melting process;

[0049] Step 4. After the first smelting ingot is completed, put the first smelting ingot into the vacuum welding box to assemble and weld the vacuum consumable electrode for the second smelting;

[0050] Step 5. Perform secondary vacuum self-consumption melting and casting on the welded seconda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com