Large cooking range for cooking

A kind of technology for large cooking pots and stoves, applied in household stoves, household stoves/stoves, applications, etc., can solve the problems of poor heat reflection characteristics, high maintenance rate, and low utilization rate of waste heat, so as to reduce the external temperature, The effect of reducing manufacturing costs and improving cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

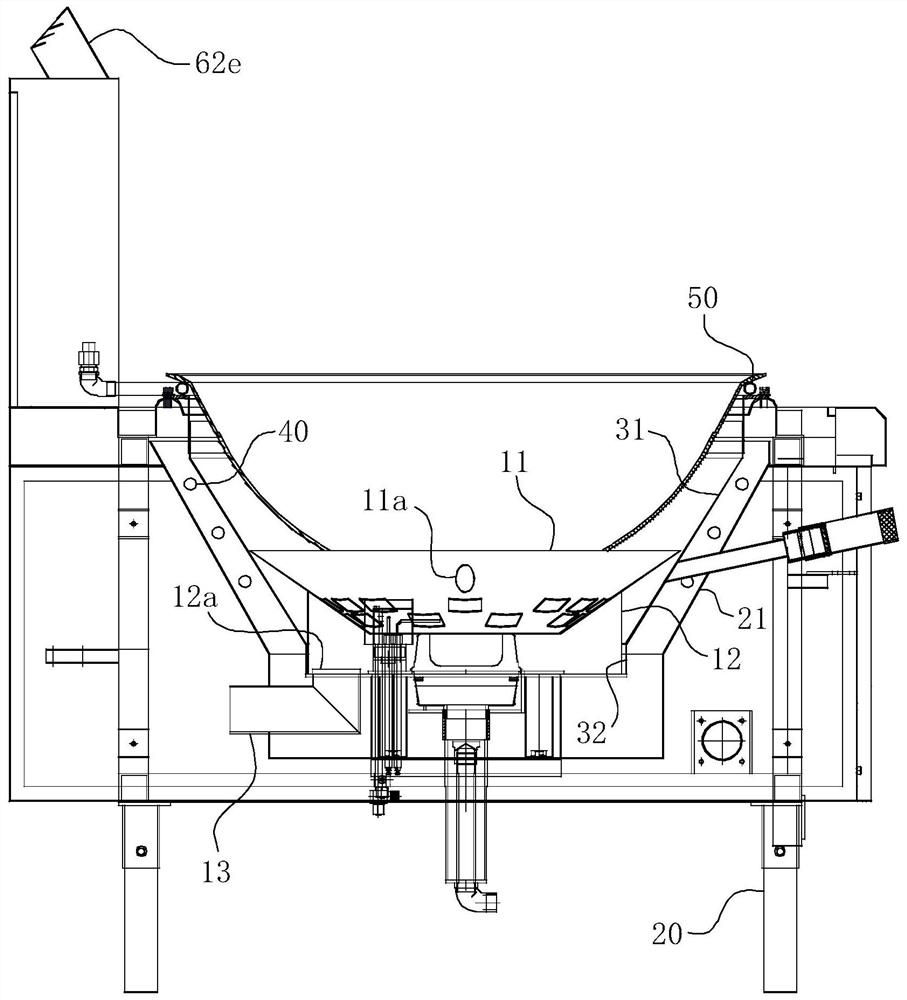

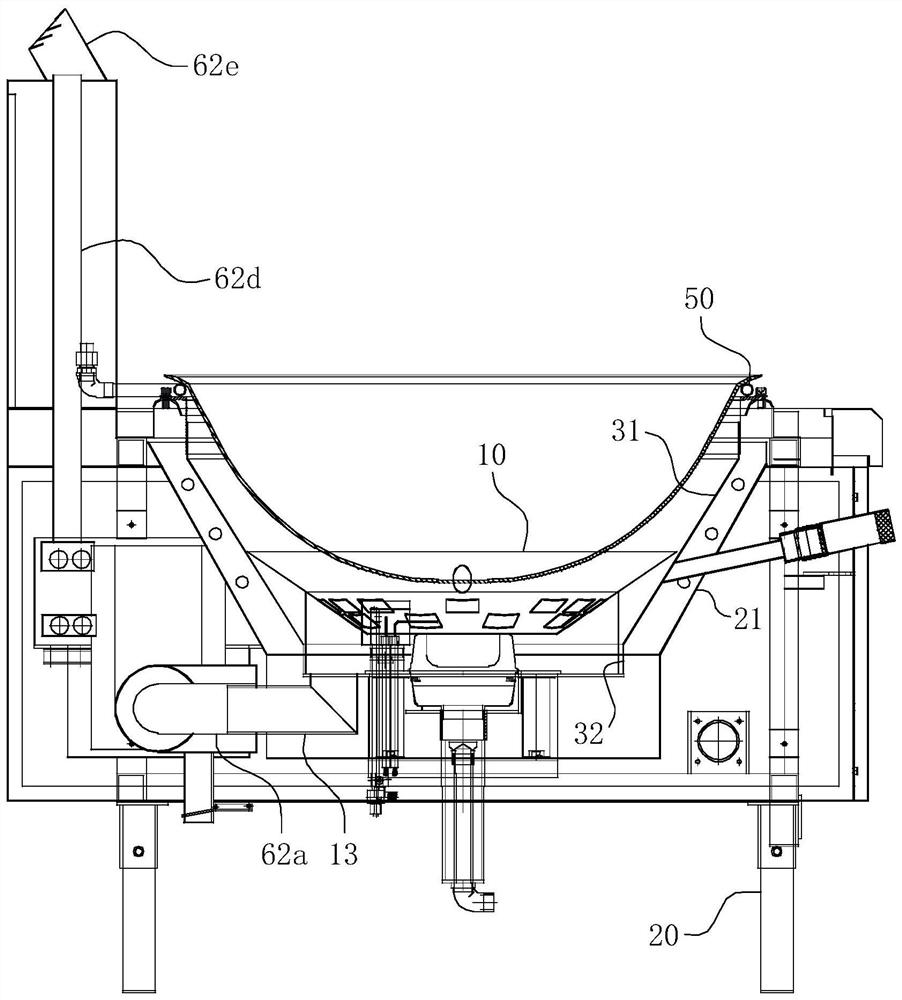

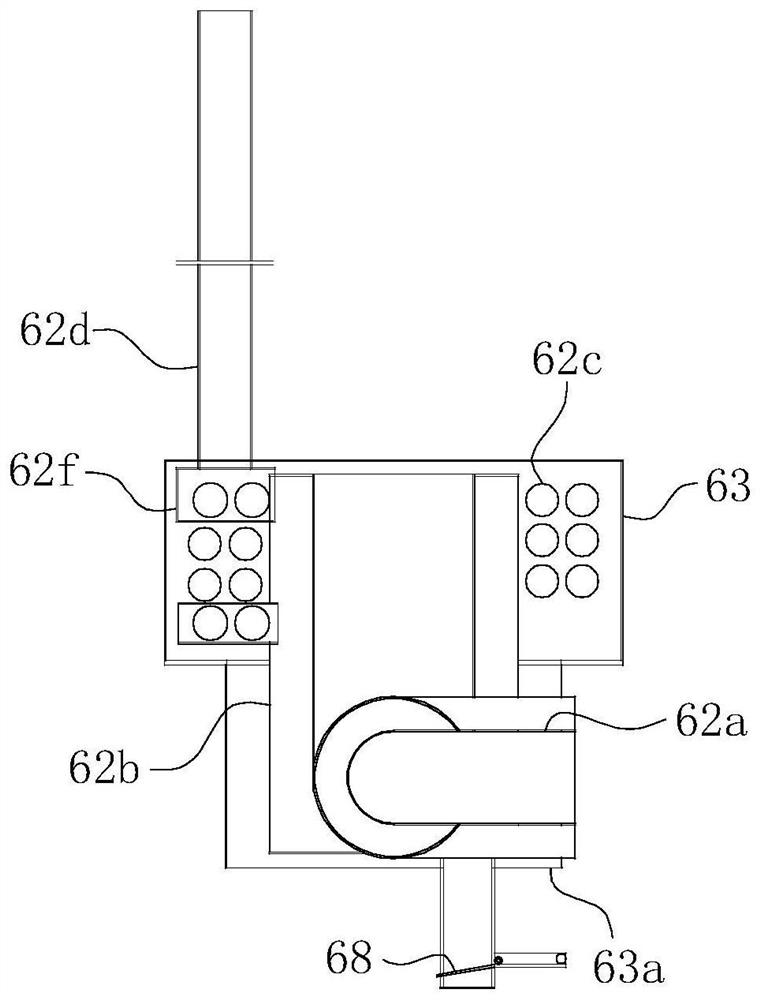

[0043] The following combination Figure 1-4 , Hot water type heat exchanger of the embodiment of the present invention will be described below:

[0044] Example Structure with reference to specific embodiments of the present invention Figure 5-6 As shown in which the main structure of the heat exchanger hob 50, the heat reflecting plate 10, the chamber, the outer housing 21, a heat exchanger coil 40 and the corresponding mating components constituting the waste heat utilization. The outer casing 21 and the furnace Figure 1-2 As shown by the refractory metal material, and showed an inverted conical; with the gap formed by the fit between the two, i.e., the fitting clearance space for heat insulation is formed windings 40 and insulation material filling. The furnace can be regarded as constituting the upper wall formed by a hearth furnace 31 and is connected to the furnace bottom 32 constituting a lower portion of the furnace. The upper furnace and the lower furnace refractory separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com