Constant control shell and tube heat exchanger

A shell-and-tube heat exchanger and heat exchanger technology, which is applied in the improvement field of hotel waste heat recovery system, can solve the problems of high pressure, uneven heat transfer, high local temperature, etc., achieve optimal relationship optimization, increase vibration range, The effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

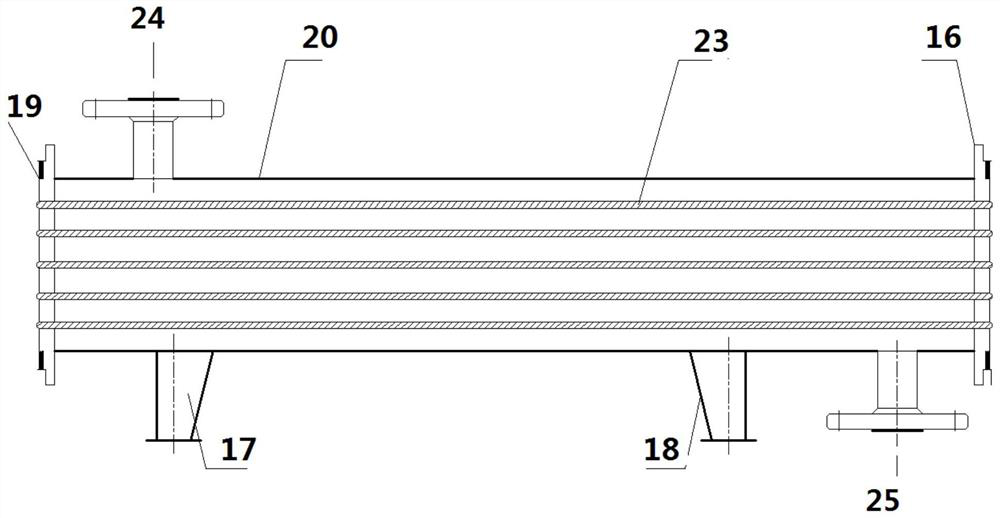

[0028] A shell-and-tube heat exchanger, such as figure 1 As shown, the shell-and-tube heat exchanger includes a shell 20, a heat exchange component 23, a shell side inlet connection 24 and a shell side outlet connection 25; the heat exchange component 23 is arranged in the shell 20, and the heat exchange component It is fixedly connected to the front tube sheet 16 and the rear tube sheet 19; the shell-side inlet connecting pipe 24 and the shell-side outlet connecting pipe 25 are both arranged on the shell 20; the fluid enters from the shell-side inlet connecting pipe 24 and passes through the heat exchange components. Heat exchange, take over 25 and go out from the shell side outlet.

[0029] Preferably, the heating member 23 extends along the vertical direction. The heat exchangers are arranged vertically.

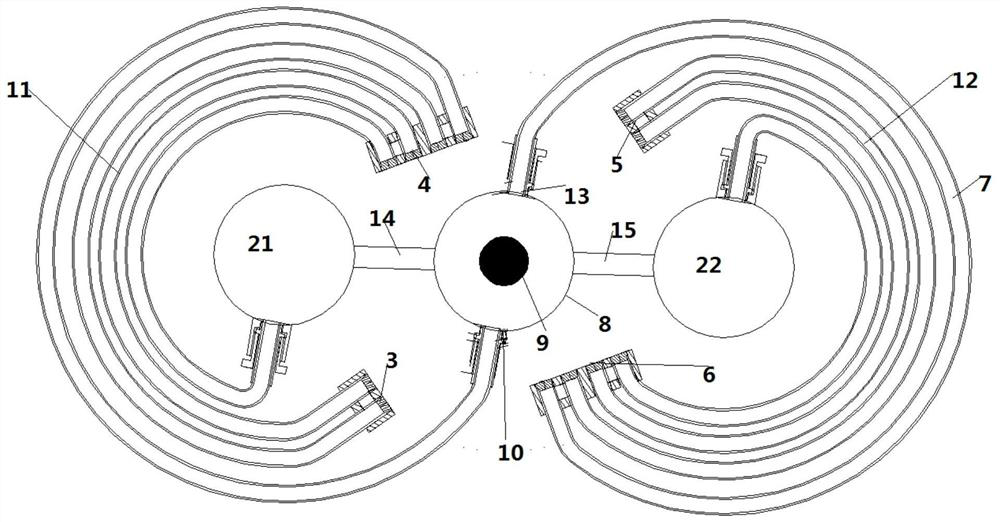

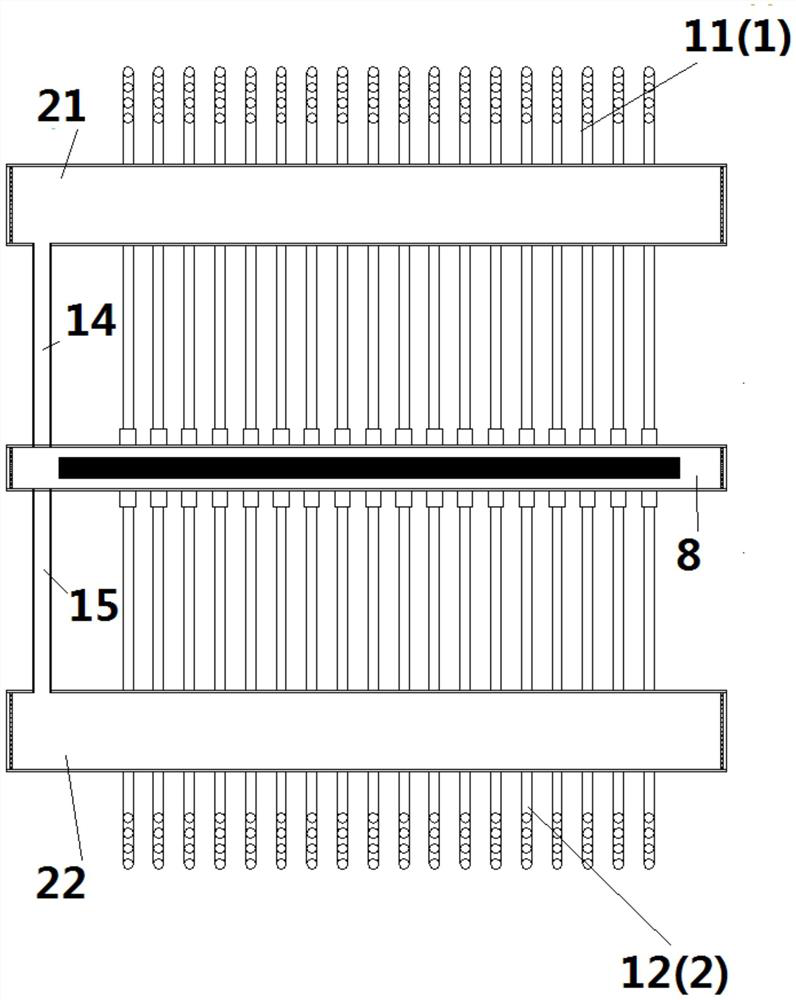

[0030] figure 2 A top view of the heat exchange component 23 is shown, as figure 2 As shown, the heat exchange component includes a central tube 8, a left side tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com