High-temperature target surface temperature measuring instrument facilitating in-furnace temperature inspection

A temperature measuring instrument and furnace temperature technology, applied in the field of temperature measuring instruments, can solve the problems of high investment cost, limited measuring points of point-type infrared thermometers, and inability to measure accurately online, and achieve the effect of eliminating measurement blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

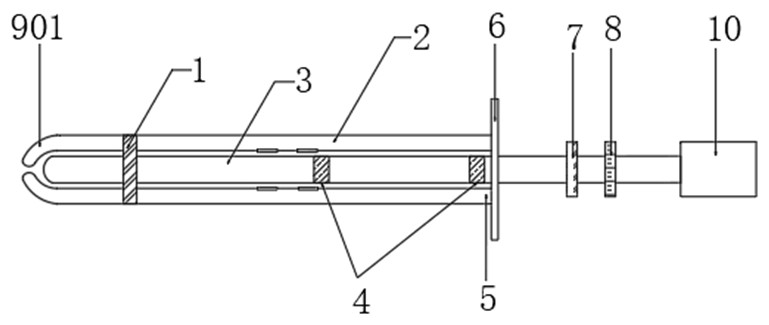

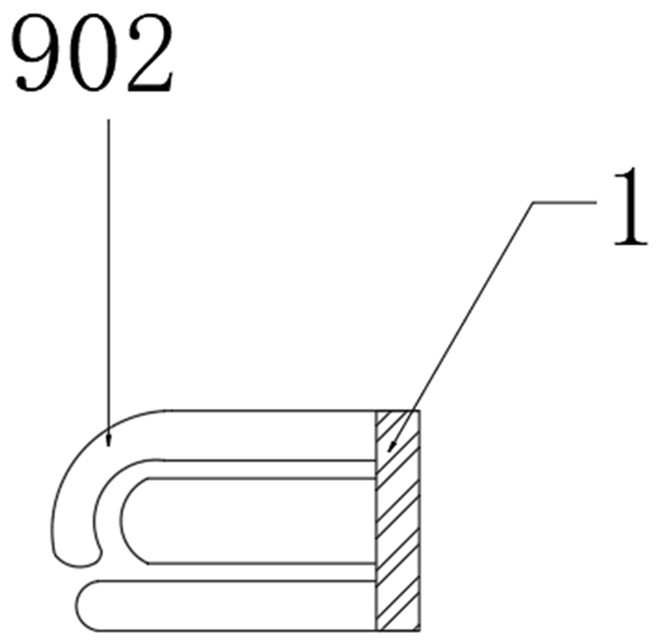

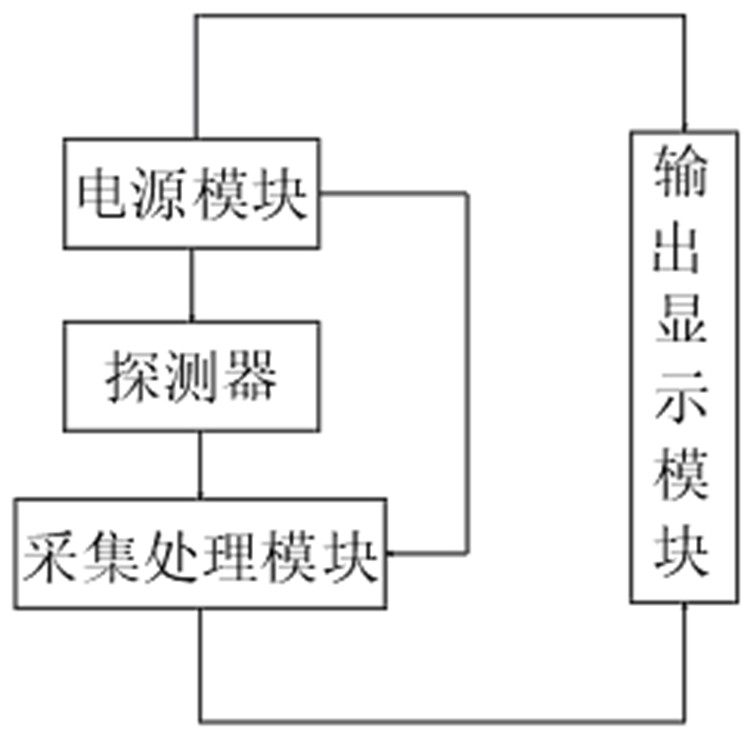

[0027] like Figure 1-2 As shown in a high temperature furnace temperature to facilitate the inspection target surface temperature measuring instrument, comprising a double protective tube 2 and the optical system, the optical system is between two double protective tube 2, the optical system is attached to the side of the inverted like the mirror extension rod 3, the front end of the protective cylinder 2 two double guard member is mounted, is provided with double protective insulation tube 2 can play a role.

[0028] In the present embodiment, one end of the curved shield member is provided with two ports, the other end of the gap, the guard member is attached to the image forming lens 1 between the two curved opening, the extension of the imaging objective lens 1 and the inversion rods 3 by means of screws connection, using a long optical lens design, increasing the field of view.

[0029] In the present embodiment, the other end of the guard shield member through the first port...

Embodiment 2

[0034] like Figure 1-3 As shown, a high-temperature target surface temperature measuring instrument that facilitates the temperature inspection of the furnace, including the double sheet guard 2 and an optical system, and the optical system is between two double-layer shields 2, and one side of the optical system is installed. Like extending the mirror rod 3, the front end of the two double-layer protective tank 2 is mounted with a guard, and the bilateral shield 2 provided can function as an insulation.

[0035] In the present embodiment, the other side of the double layer shield 2 is mounted having a protective plate 6, the thickness of the guard plate 6 can effectively block high temperature observations.

[0036] In the present embodiment, the optical system on the side of the guard plate 6 is attached to the side of the narrow bandwidth filter 7, and the other side mounting focus lens 8, the other side of the focus lens 8 is attached to the other side of the focus lens 8 mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com