Building curtain wall safety nondestructive testing imaging method based on microwave imaging

A microwave imaging and non-destructive testing technology, applied in radio wave measurement systems, radio wave reflection/re-radiation, measurement devices, etc. Frequent problems such as avoiding accidental factors, good detection effect, and improving personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

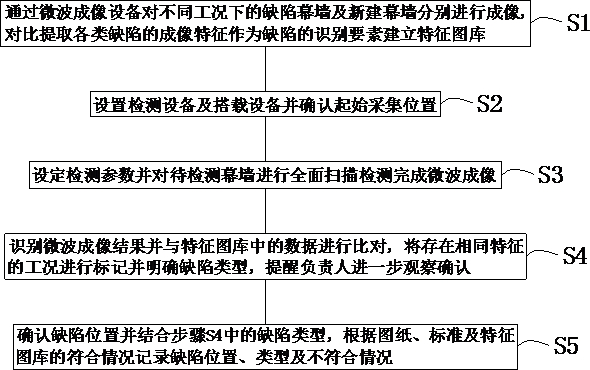

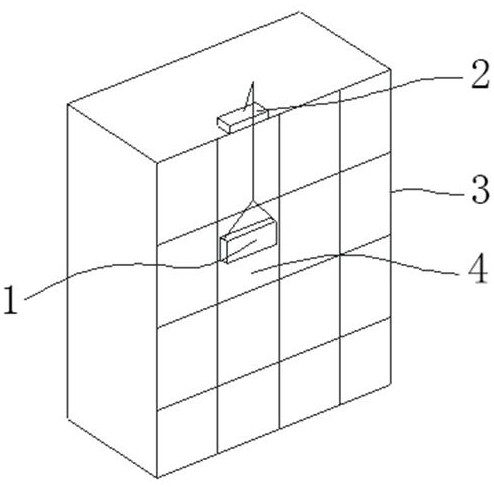

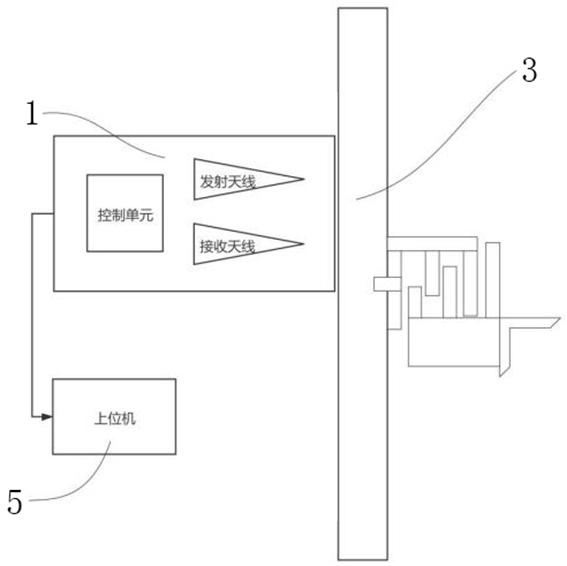

[0030] refer to Figure 1 to Figure 3 As shown, the present invention provides a method for non-destructive detection and imaging of building curtain walls based on microwave imaging. The method is based on the principle that curtain wall materials, distribution positions and materials have different microwave reflection and absorption coefficients. The same side receives the reflection signal after the penetrating panel, sealant, etc. touch the metal, and after analyzing the imaging, it intuitively displays and marks the relevant defects, including the following steps:

[0031] S1, using microwave imaging equipment to image the defective curtain wall and the new curtain wall under different working conditions, and compare and extract the imaging features of various defects as defect identification elements to establish a feature library; fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com