Packaging structure and optical module

A packaging structure and packaging substrate technology, which is applied in the field of optical communication, can solve the problems of reducing the optical bandwidth and affecting the quality of high-frequency signal transmission, and achieve the effects of improving the optical bandwidth, reducing coupling, and good high-frequency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

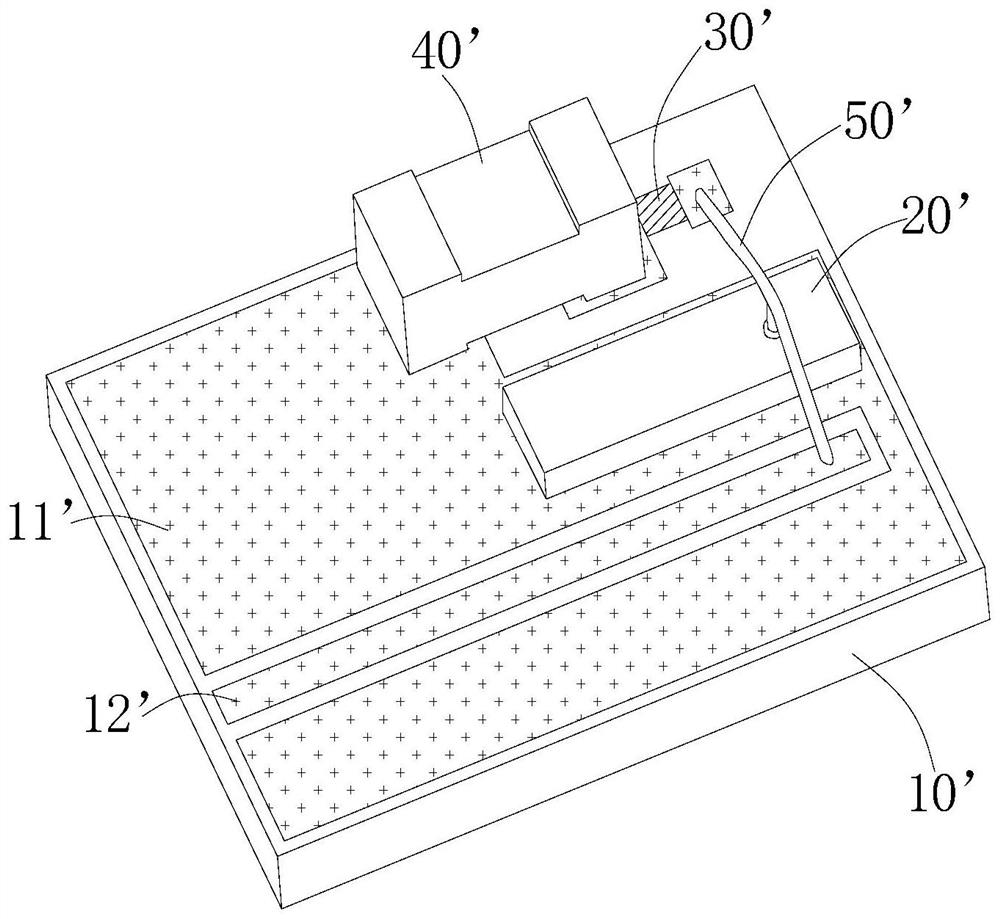

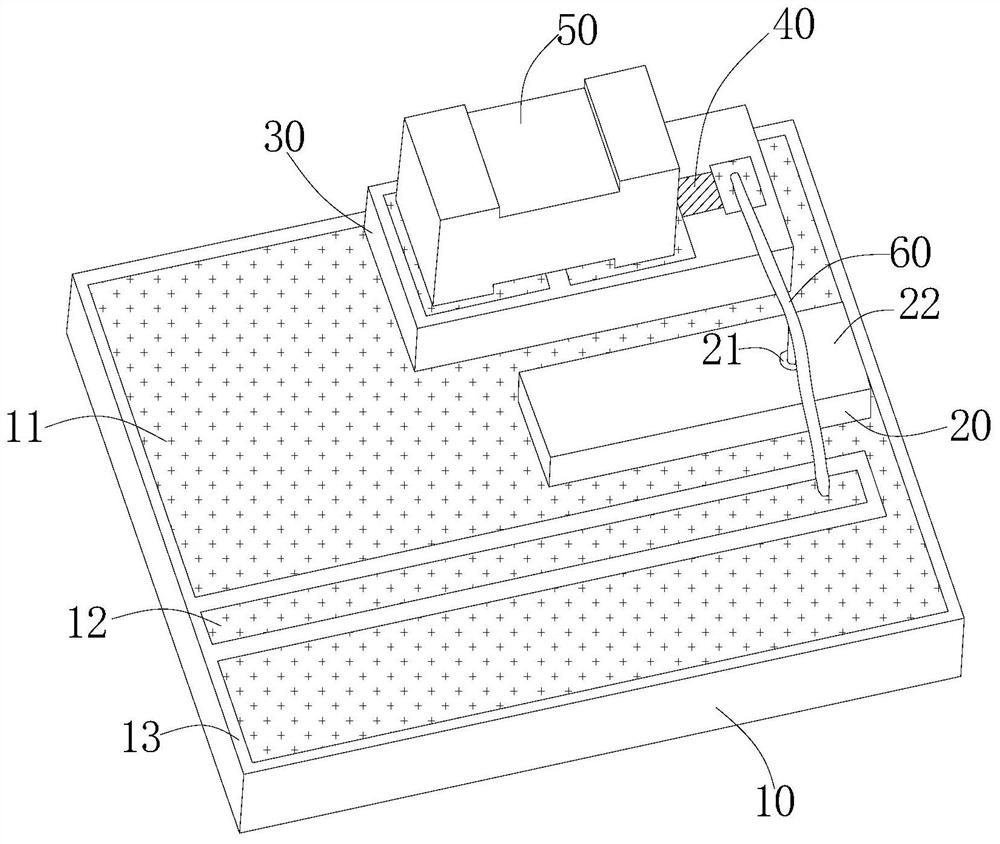

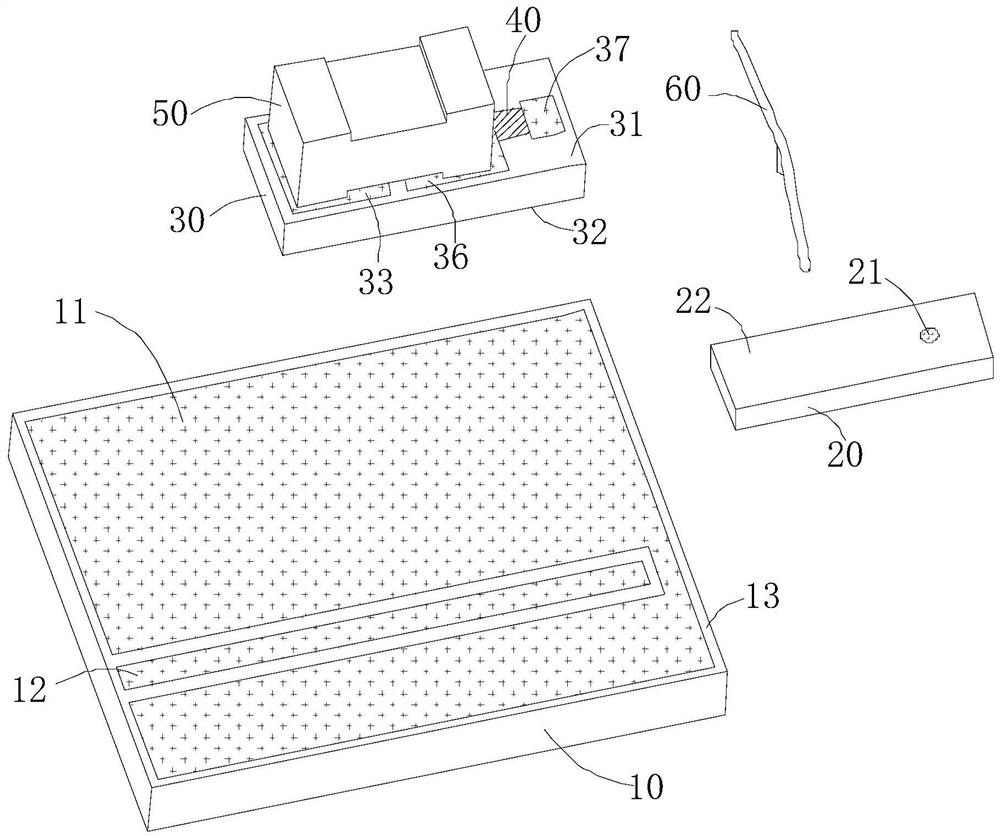

[0037] Such as Figure 2-4 As shown, this embodiment provides a COC (chip on ceramic, chip on ceramic substrate) packaging structure, including a packaging substrate 10 and at least one semiconductor laser chip 20 and at least one sub-substrate disposed on the packaging substrate 10 30 and a matching circuit. In this embodiment, there is a single semiconductor laser chip 20 and a single sub-substrate 30 on the package substrate 10 . A ground metal 11 and at least one signal line 12 are provided on the package substrate 10 , here, corresponding to a single semiconductor laser chip 20 , a single signal line 12 is provided on the package substrate 10 . In this embodiment, the upper surface of the packaging substrate 10 has a metal layer, and the signal line is formed on the metal layer to form the ground metal 11 and the signal line 12 with a coplanar line structure on the upper surface of the packaging substrate 10. Here, the packaging The upper surface of the substrate 10 is t...

Embodiment 2

[0041] Such as Image 6 As shown, the difference from Embodiment 1 is that in this embodiment, the above-mentioned packaging substrate 10 is provided with a first upper surface 13 and a second upper surface 14, and the signal line 12 and the semiconductor laser chip 20 of the packaging substrate 10 are arranged on the second upper surface. On the first upper surface 13 , the sub-substrate 30 is disposed on the second upper surface 14 , wherein the height of the second upper surface 14 is lower than that of the first upper surface. Here, the first upper surface 13 is the same as the upper surface of the package substrate in Embodiment 1, and has the signal line 12 and the ground metal 11 with a coplanar line structure. Specifically, a stepped plane is made on the side of the packaging substrate 10 away from the signal line 12 as the second upper surface 14, and the second upper surface 14 is lower than the first upper surface 13 of the packaging substrate 10, so that the device...

Embodiment 3

[0044] Such as Figure 7 As shown, the difference from Embodiment 2 is that in this embodiment, the packaging substrate 10 is also provided with a third upper surface 15, that is, the packaging substrate 10 is provided with a first upper surface 13, a second upper surface 14 and a third upper surface. Surface 15. Wherein, the height of the second upper surface 14 is lower than that of the third upper surface 15 , and the height of the third upper surface 15 is lower than that of the first upper surface 13 . Here, the first upper surface 13 is the same as the upper surface of the package substrate in Embodiment 1, and has a signal line 12 and a ground metal 11 with a coplanar line structure, the sub-substrate 30 is arranged on the second upper surface 14, and the semiconductor laser 20 is arranged on the second upper surface 14. on the third upper surface 15 . In this embodiment, the third upper surface 15 is located between the second upper surface 14 and the signal line 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com