Treatment method and treatment system for organic matter-containing gas

A treatment method and technology for organic matter, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of low gas flux in the absorption subsystem, failure to meet processing requirements, high organic matter removal rate, etc., and achieve complete The effect of removing organic matter, reducing process cost and improving absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

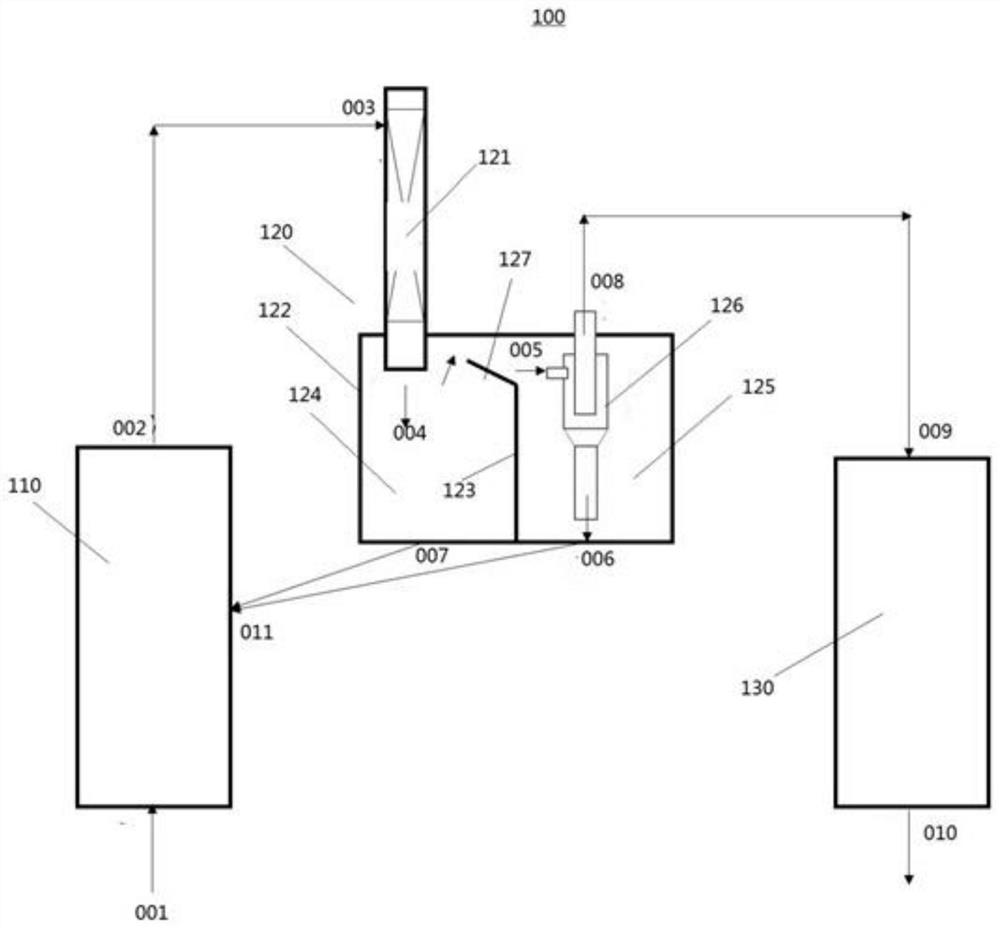

[0047] This embodiment provides a treatment method for gas containing organic matter, which adopts figure 1 The devices in are processed as follows:

[0048] Fill the absorption unit 110 with an absorbent (hydrocarbons and mercaptans with a boiling point of 150-250° C., a mixture obtained by mixing them at a volume ratio of 1:1), and the adsorption unit 130 is filled with an adsorbent (made of carbon, with pores less than 2nm and 2 The pore volume ratio of -10nm pores is 1:2, and the pore volume ratio of below 10nm is 95%). The forced mixing section 121 in the mixing and defoaming unit 120 is filled with wire mesh packing with a porosity of 91%.

[0049] The gas containing organic matter (the main gas is nitrogen, the organic matter is C7 ketones, and the concentration of organic matter is 10000mg / m 3 ), from the gas inlet 001 into the absorption unit 110, the gas velocity is controlled at 0.5m / s, the temperature is at -5°C, the pressure is 0.2MPa, and the residence time of ...

Embodiment 2

[0055] This embodiment provides a treatment method for gas containing organic matter, which adopts figure 1 The devices in are processed as follows:

[0056] Fill the absorption unit 110 with an absorbent (a mixture of esters and ketones with a boiling point of 200-250° C., mixed at a volume ratio of 1:1), and the adsorption unit 130 is filled with an adsorbent (made of carbon, with pores less than 2 nm and 2- The pore volume ratio of 10nm pores is 1:3, and the pore volume ratio of below 10nm is 90%). The forced mixing section 121 in the mixing and defoaming unit 120 is filled with wire mesh packing with a porosity of 90%.

[0057] The gas containing organic matter (the main gas is 50% hydrogen and 50% He, the organic matter is a mixture of C10 esters in any proportion, the concentration of organic matter is 500mg / m 3 ), from the gas inlet 001 into the absorption unit 110, the gas velocity is controlled at 1m / s, the temperature is at 10°C, the pressure is 2MPa, and the resid...

Embodiment 3

[0063] This embodiment provides a treatment method for gas containing organic matter, which adopts figure 1 The devices in are processed as follows:

[0064] Fill the absorption unit 110 with an absorbent (a mixture of alcohols, esters, and amines with a boiling point of 150-180°C, mixed at a volume ratio of 1:1:1), and the adsorption unit 130 is filled with an adsorbent (made of carbon, less than 2nm The pore volume ratio of pores to 2-10nm pores is 1:4, and the pore volume ratio of pores below 10nm is 50%). The forced mixing section 121 in the mixing and defoaming unit 120 is filled with wire mesh packing with a porosity of 95%.

[0065] The gas containing organic matter (the main gas is a mixture of CO and Ar in any ratio, the organic matter is C5 hydrocarbons, the ratio of alcohols to ketones is roughly 1:1:1, and the concentration of organic matter is 20000mg / m 3 ), from the gas inlet 001 into the absorption unit 110, the gas velocity is controlled at 0.7m / s, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com