Preparation method of bulk phase loaded zero-valent iron biochar material

A technology of biochar and phase loading, which is applied in chemical instruments and methods, water/sludge/sewage treatment, adsorption water/sewage treatment, etc. It can solve the problems that the stability needs to be improved, and achieve improved reliability and durability, The effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1

[0042] Planting ramie is 130 days in red soil, and 200 mg / L citric acid solution is sprayed once a week. After 130 days, cutting the narcles. Using deionized water was washed with a 0.01 M dilute hydrochloric acid for 1 hour, and the pulverized to 2 mm particles were dried at 70.0 ° C. In the tube muffle furnace, the pulverized particles were hotly solved for 90 minutes at 700 degrees Celsius, and the adamant phase load zero-price iron bio-carbon material was prepared.

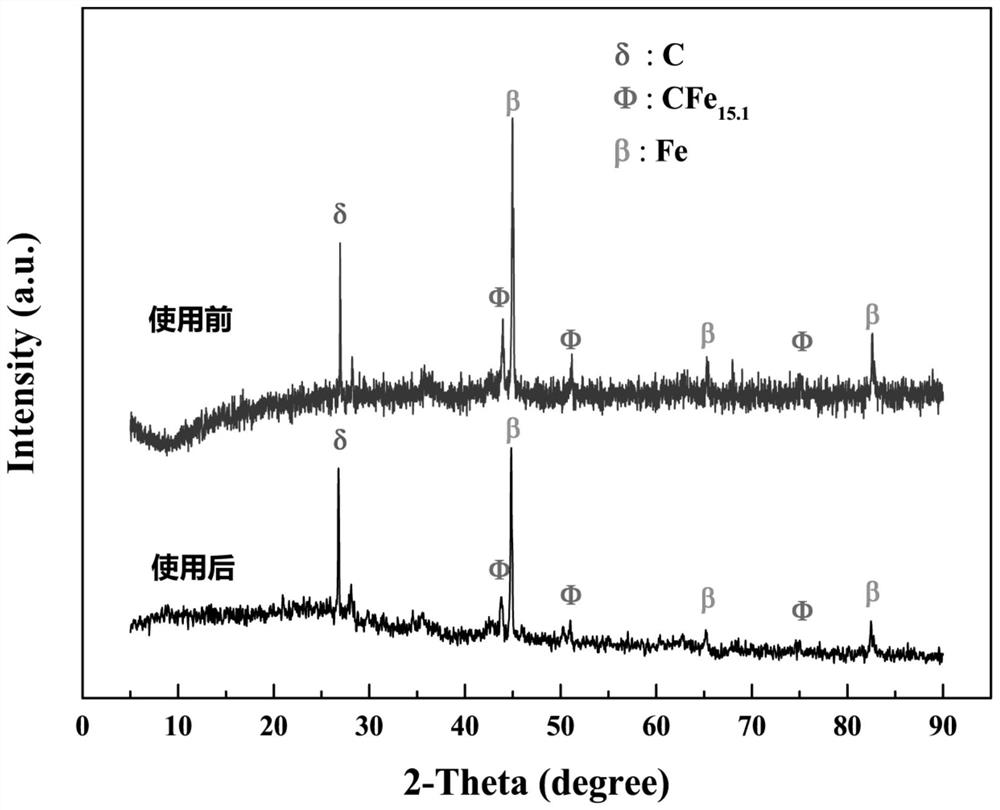

[0043] XRD spectrum of zero price iron bio-carbon material figure 1 As shown, 44.8 °, 65.1 °, 82.2 ° are zoi iron diffraction peaks, and 43.1 °, 50.4 °, 73.9 ° are iron carbon compound CFE. 15.1 Diffraction peaks.

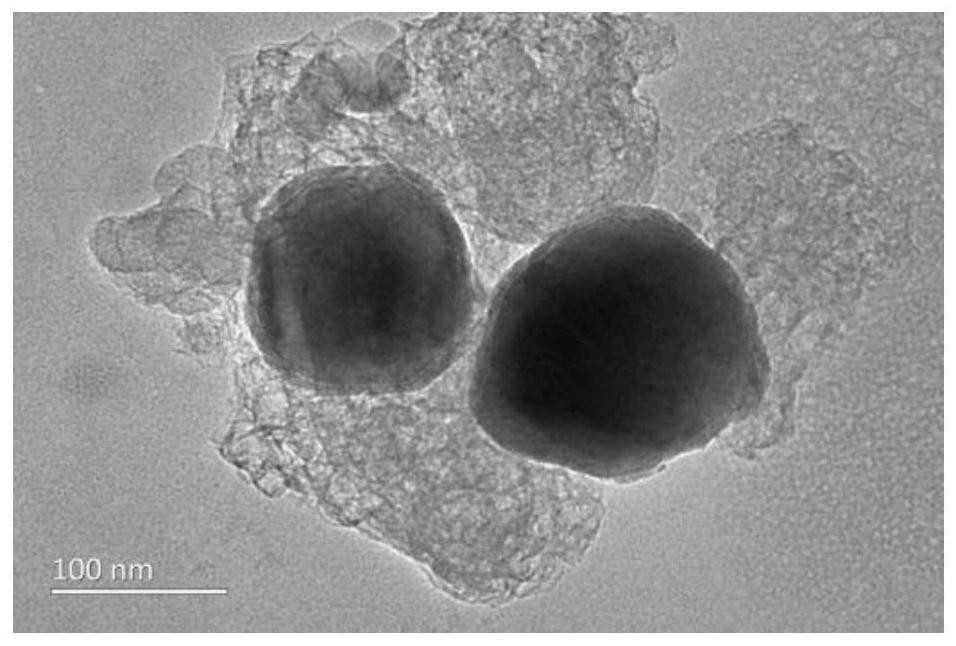

[0044] The TEM of the body-phase load zizi iron bio-carbon material reveals that the zero-valent iron particles are bored in the biological carbon phase.

[0045] The XPS of the body-phase load zizi iron bio-carbon material reveals that the zero-price iron content at the surface of...

Embodiment 2

[0047] Planted ramie for 150 days and 150 days after 150 days. Using deionized water was washed with a 0.01 M dilute hydrochloric acid for 1 hour, and the pulverized to 2 mm particles were dried at 70.0 ° C. In the tubular muffle furnace, the pulverized particles are hotly solved at 600 degrees Celsius, and the adamant phase load zero-price iron bio-carbon material is prepared.

[0048] The XRD and TEM Results of the body phase load zizi iron bio-carbon material were similar to those in Example 1.

[0049] Its XPS reveals that the zero price iron content at 40 nm depth and 80 nm depth is 1.38%, 8.98% and 18.32, respectively.

Embodiment 3

[0051]Planting ramie is 150 days in red soil, and a solution of 100 mg / L of citric acid is sprayed once a week. After 150 days, cutting the narcles. Using deionized water was washed with a 0.01 M dilute hydrochloric acid for 1 hour, and the pulverized to 2 mm particles were dried at 70.0 ° C. In the tubular mass furnace, the pulverized particles are hotly solved at 800 degrees Celsius, and the adamant phase load zero-price iron bio-carbon material is prepared.

[0052] The XRD and TEM Results of the body phase load zizi iron bio-carbon material were similar to those in Example 1.

[0053] Its XPS reveals that the zero price iron content at 40 nm depth and 80 nm depth is 1.43%, 9.06% and 18.44, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com