Method for cleaning residual soldering flux on surface of IGBT module

A surface residue and flux technology, which is applied in the field of IGBT module surface residue flux cleaning, can solve problems such as increased product scrap rate, and achieve the effects of facilitating cost control, ensuring production yield, and reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

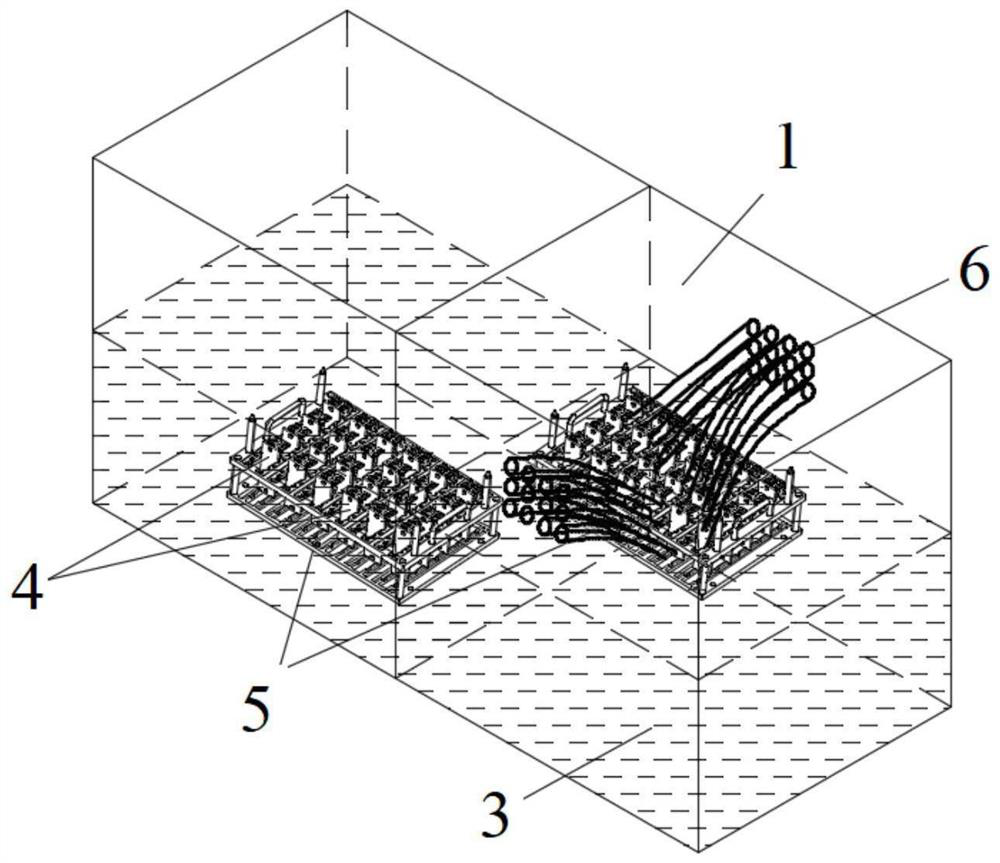

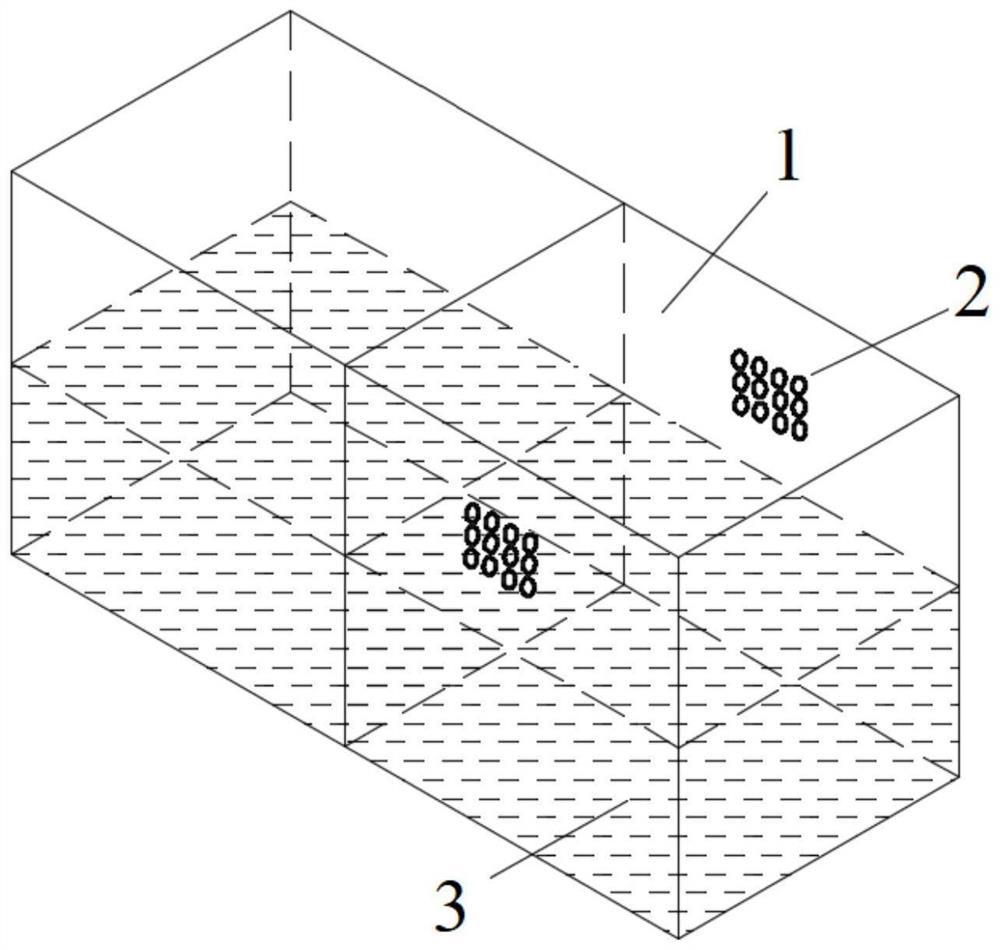

[0016] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0017] Such as figure 1 and figure 2 As shown, the present invention provides a method for cleaning residual flux on the surface of an IGBT module, comprising the steps of:

[0018] S1. Provide cleaning liquid spraying device 6;

[0019] S2. After the IGBT module is removed from the cleaning solution of the washing machine, the cleaning solution spraying device 6 performs spraying and rinsing operations on the IGBT module.

[0020] Specifically, as figure 1 and figure 2 As shown, the cleaning machine has a cleaning tank 1 containing cleaning liquid, and the IGBT module is placed in the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com