A kind of hot-rolled steel strip for 750mpa grade coiled tubing and its manufacturing method

A manufacturing method and technology of hot-rolled steel, applied in the field of steel for oil well pipelines, can solve the problems of repeated plastic deformation, poor deformability, unfavorable toughness and welding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

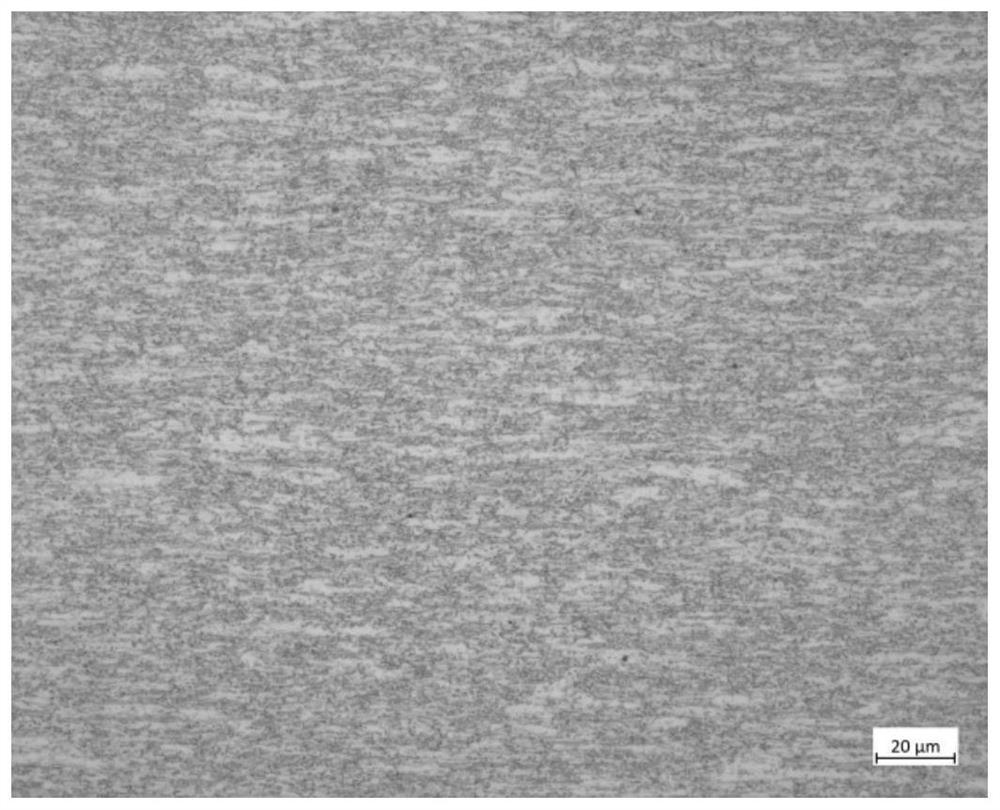

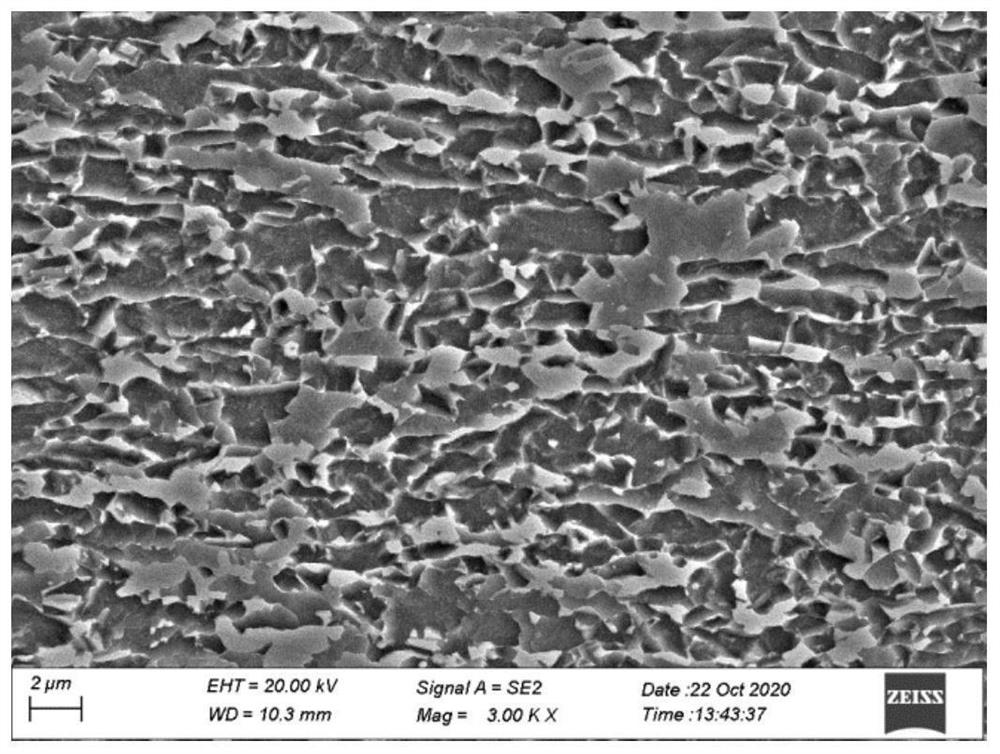

[0036] The hot-rolled steel strip for 750MPa grade coiled tubing in this embodiment has the following chemical components by weight: C: 0.12%-0.14%, Si: 0.30%-0.40%, Mn: 1.50%-2.00%, P: ≤0.015%, S: ≤0.0050%, Cr: 0.50% to 0.70%, Cu: 0.10% to 0.40%, Ni: 0.10% to 0.30%, Mo: 0.20% to 0.50%, Nb: 0.050% to 0.070%, V: 0.040-0.050%, Ti: 0.010-0.020%, Als: 0.020-0.035%; the rest are Fe and inevitable inclusions; the thickness of the produced hot-rolled steel strip is 3-5mm, and its metallographic structure is iron Element body + martensite structure, grain size ≥ 12, banded structure ≤ 1.5. The yield strength of the produced hot-rolled steel strip is 782-809MPa, and the tensile strength is 1077-1143MPa, which can meet the needs of hot-rolled steel strip for coiled tubing in ultra-deep wells.

Embodiment 2

[0038] The manufacturing method of a 750MPa grade coiled tubing hot-rolled steel strip of the present embodiment, the basic structure is the same as that of the embodiment 1, and the difference and improvement lie in that: it includes the following steps:

[0039] Step 1, molten iron pretreatment: control the molten iron [S] after desulfurization ≤ 0.0050%;

[0040] Step 2, converter smelting: the argon station is subjected to strong stirring at the top and bottom, and the strong stirring time is ≥4min, the P is removed during the strengthening process, and the deoxidation alloying is carried out during tapping to strengthen the slag blocking operation;

[0041] Step 3. Refining in LF furnace: the ladle top slag is fully reduced, the composition is adjusted to the target value or close to the target value, and the exit temperature: 1600-1615 °C;

[0042] Step 4. RH furnace refining: vacuum degree ≤ 2.6mbar, vacuum time ≥ 12min, adjust all components to the target value;

[00...

Embodiment 3

[0051] The manufacturing method of a hot-rolled steel strip for 750MPa grade coiled tubing in this embodiment, the basic structure is the same as that of Embodiment 2, and the difference and improvement are: using molten iron pretreatment → converter steelmaking → LF refining outside the furnace → outside the RH furnace Refining → continuous casting → hot rolling. After refining outside the LF furnace, the chemical composition in the steel meets the weight percentage (wt%): C: 0.12% ~ 0.14%, Si: 0.30% ~ 0.40%, Mn: 1.50% ~ 2.00%, P: ≤ 0.015%, S : ≤0.0050%, Cr: 0.50% to 0.70%, Cu: 0.10% to 0.40%, Ni: 0.10% to 0.30%, Mo: 0.20% to 0.50%, Nb: 0.050% to 0.070%, V: 0.040 to 0.050 %, Ti: 0.010-0.020%, Als: 0.020-0.035%; the rest are Fe and inevitable inclusions.

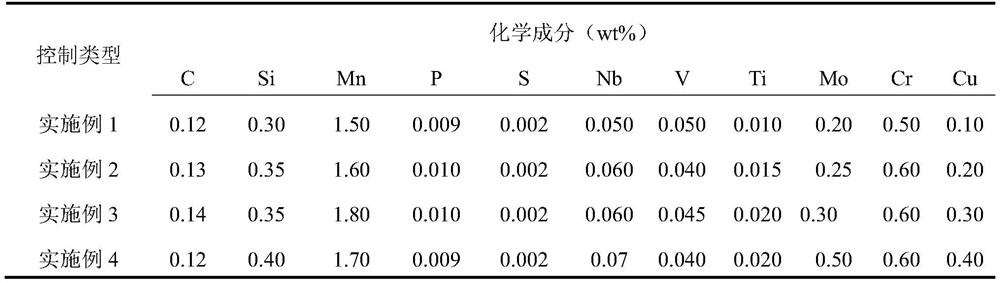

[0052] Table 1 shows the chemical composition of each example during the experiment. The composition detection was carried out according to GB / T 4336 "Carbon Steel and Medium and Low Alloy Steel Spark Source Atomic Emissio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com