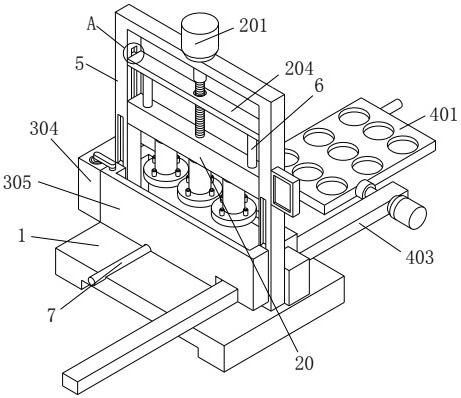

A hydraulic pump compressive strength load detection device and its implementation method

A compressive strength and load detection technology, which is applied in the field of hydraulic pumps, can solve problems such as inability to improve detection efficiency, lack of protection functions, and reduce detection efficiency, and achieve effective and rapid detection, improve efficiency, and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

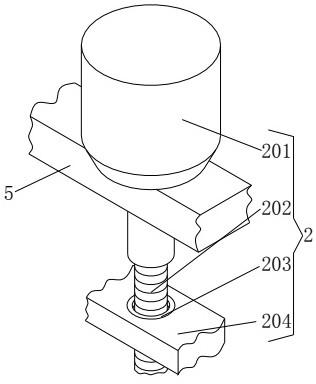

[0057] In order to further and better explain the above-mentioned embodiments, the present invention also provides an adjustment method, an implementation method of a hydraulic pump pressure resistance load detection device, including the following steps:

[0058] S1: Place the material to be detected in the inner cavity of the positioning hole 10, and then drive the installation rod 402 to move through the electric slide rail 403, the movement of the installation rod 402 drives the detection mold 401 to move, and move the material to be detected to the infrared sensor 17 s position;

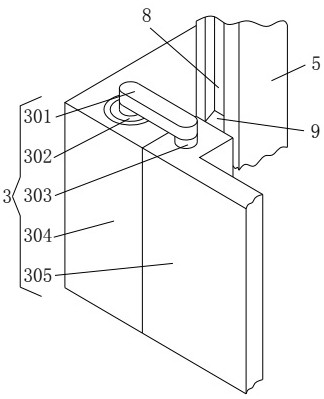

[0059] S2: After the infrared sensor 17 senses the material, the cylinder 302 starts to run, the cylinder 302 drives the connecting rod 301 to move, the movement of the connecting rod 301 drives the fixed block 303 to move, and the movement of the fixed block 303 drives the protective plate 305 to move, so that the protective plate 305 Protect the material that needs to be detected, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com