Acellular matrix fiber sponge, and preparation method and application thereof

An acellular matrix and fiber technology, applied in the field of acellular matrix fiber sponge and its preparation, can solve the problems of secondary tearing, easy growth into the sponge, etc., and achieve the effect of reducing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

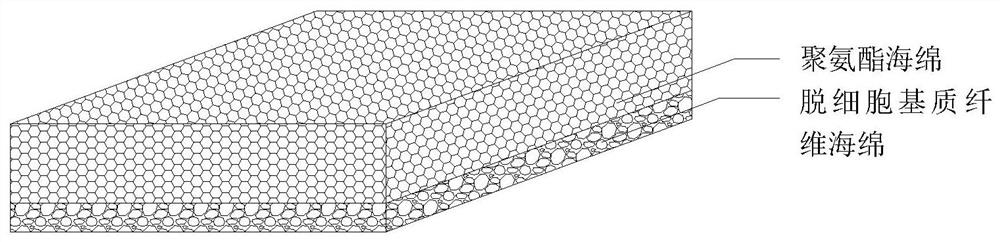

[0029] Such as figure 1 As shown, the present embodiment provides a kind of acellular matrix fiber sponge, and its preparation steps include:

[0030] S1. Take the wet acellular matrix and cut it into a size less than 1cm 2 After the fragments, carry out high-speed mashing in a short time (no more than 1min);

[0031] S2. Take 0.5% (wet weight) of the acellular matrix, 0.01% glacial acetic acid and the rest of purified water by weight percentage, mix and cool down to 2°C;

[0032] S3. Perform homogenization at a frequency of 25 Hz, and then homogenize the collected feed liquid 3 times, filter out coarse particles, and use a 6% NaOH solution to adjust the pH of the filtered slurry to 7.0 , to obtain decellularized matrix fibers after centrifugation;

[0033] S4. Take the acellular matrix fiber, make an aqueous dispersion with a mass fraction of 0.5%, and adjust the pH value to 4; cover the acellular matrix fiber with a polyurethane sponge layer or a polyvinyl alcohol sponge ...

Embodiment 2

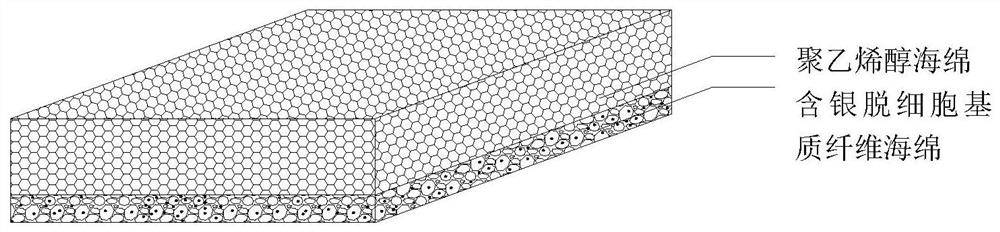

[0036] Such as figure 2 As shown, the present embodiment provides another acellular matrix fiber sponge, the steps of its preparation comprising:

[0037] S1. Take the wet acellular matrix and cut it into a size less than 1cm 2 After the fragments, carry out high-speed mashing in a short time (no more than 1min);

[0038] S2. Take 3.0% (wet weight) of the acellular matrix, 0.1% glacial acetic acid and the rest of purified water by weight percentage, mix and cool down to 8°C;

[0039] S3. Perform homogenization at a frequency of 29 Hz, and then homogenize the collected feed liquid 3 times, filter out coarse particles, and use an 8% NaOH solution to adjust the pH of the filtered slurry to 7.5 , to obtain decellularized matrix fibers after centrifugation;

[0040] S4. Take the acellular matrix fiber, make an aqueous dispersion with a mass fraction of 10%, adjust the pH value to 8, and then add silver sulfadiazine dispersion according to the solid content until the silver elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com