Manipulator device for drilling of numerical control tool magazine machine tool

A technology of manipulators and machine tools, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as not suitable for batch parts processing, wrong tool head replacement, cumbersome tool changing steps, etc., to save tool changing time and ensure Reliability, vibration prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

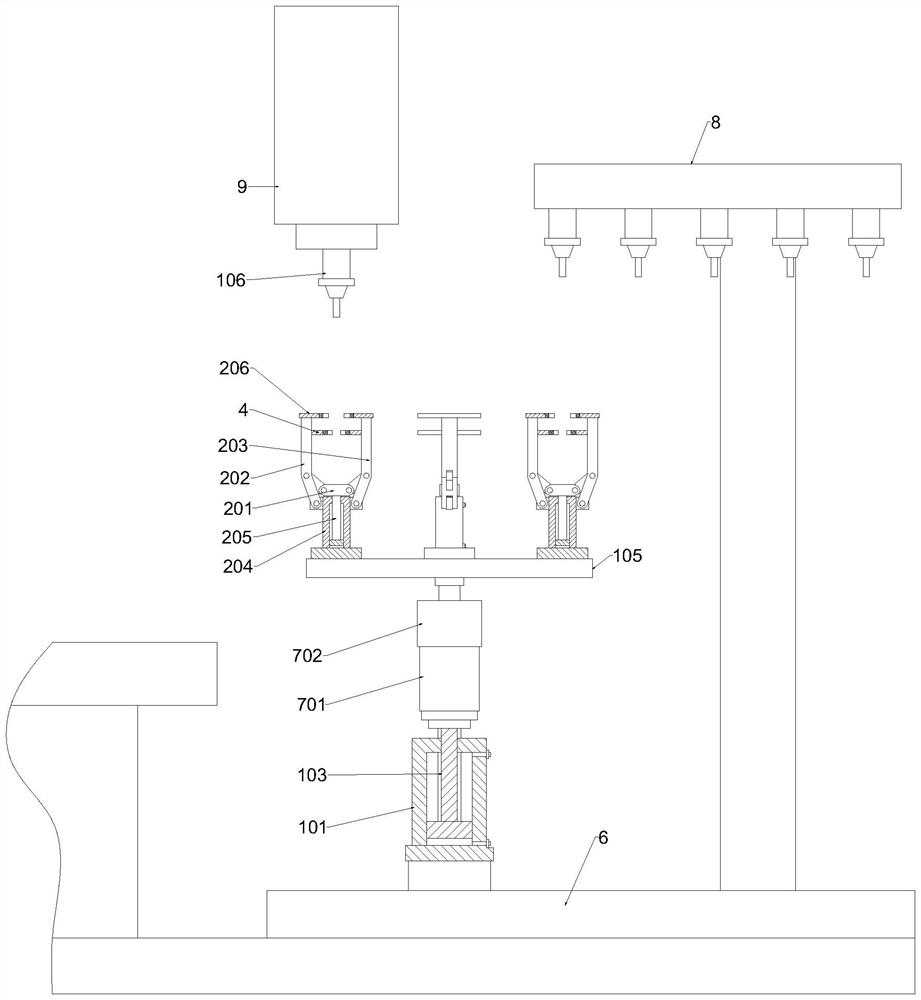

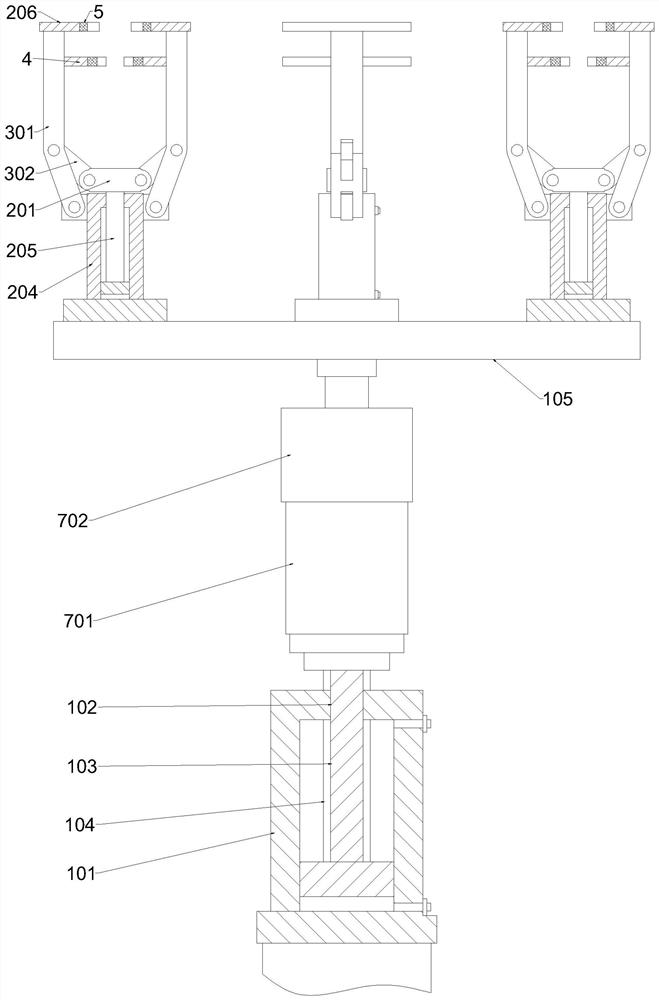

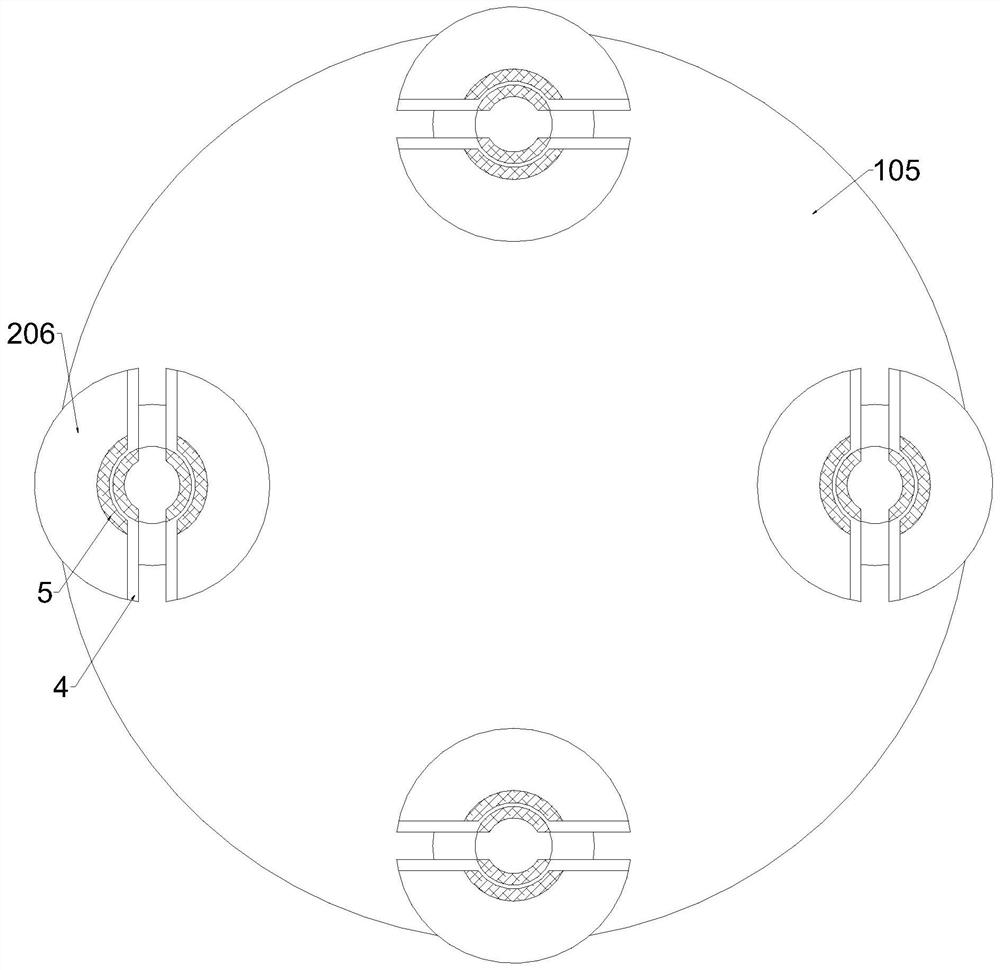

[0024] Such as Figure 1-3 As shown, the present invention provides a manipulator device for hole turning of a CNC tool magazine machine tool, comprising: a first double-acting hydraulic cylinder, a power unit, a turntable 105 and a plurality of gripper mechanisms, and the first double-acting hydraulic cylinder is located in the machine tool , the first cylinder 101 of the first double-acting hydraulic cylinder is provided with a spline hole 102, and the first piston 103 of the first double-acting hydraulic cylinder is provided with a spline groove 104 matching the spline hole 102, so The spline hole 102 is slidingly connected to the spline groove 104, the first cylinder 101 is connected with a liquid supply device; the power device is fixedly connected to the rod of the first piston 103, and the power device is electrically connected to a controller , the controller is electrically connected to a power supply device; the rotation center of the turntable 105 is connected to th...

Embodiment 2

[0029] On the basis of Embodiment 1, in order to facilitate the clamping and releasing operations.

[0030] Such as figure 1 and 2 As shown, wherein, the gripper mechanism includes a second double-acting hydraulic cylinder, a connecting block 201, a first link mechanism 202, a second link mechanism 203, and the second cylinder body 204 of the second double-acting hydraulic cylinder Fixedly connected to the turntable 105, the second cylinder 204 communicates with the liquid supply device, the connecting block 201 is connected to the second piston 205 of the second double-acting hydraulic cylinder, and the first linkage mechanism 202 The second link mechanism 203 is opposite to the second piston 205, the first link mechanism 202 and the second link mechanism 203 are hinged with the connecting block 201, the first link mechanism 202 and the second link mechanism 203 can be driven by the rod of the second piston 205 to approach or move away from each other. The ends of the first...

Embodiment 3

[0033] On the basis of Embodiment 2, in order to enable the free end of the first connecting rod 301 to have a larger movable stroke, so that the first clamping plate has a larger movable range, thereby facilitating the clamping of the cutter head 106 .

[0034] Such as figure 2 As shown, wherein, the first link mechanism 202 and the second link mechanism 203 have the same structure and both include a first link 301 and a second link 302, and one end of the first link 301 is hinged to the second link. On the side wall of the cylinder body 204, the first arc splint 206 is arranged at the other end of the first connecting rod 301, one end of the second connecting rod 302 is hinged on the connecting block 201, and the other end of the second connecting rod 302 Hinged to the shaft of the second connecting rod 302 .

[0035] When clamping the cutter head 106, the second piston 205 is retracted into the second cylinder 204 through the oil supply of the liquid supply device, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com