Tool changing drilling device for production of numerical control tool magazine machine tool

A drilling device and machine tool technology, applied in the field of CNC machine tools, can solve the problems of personal injury, poor tool support in the tool magazine, affecting the normal use of the machine tool, etc., to improve the processing quality and facilitate the tool change operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

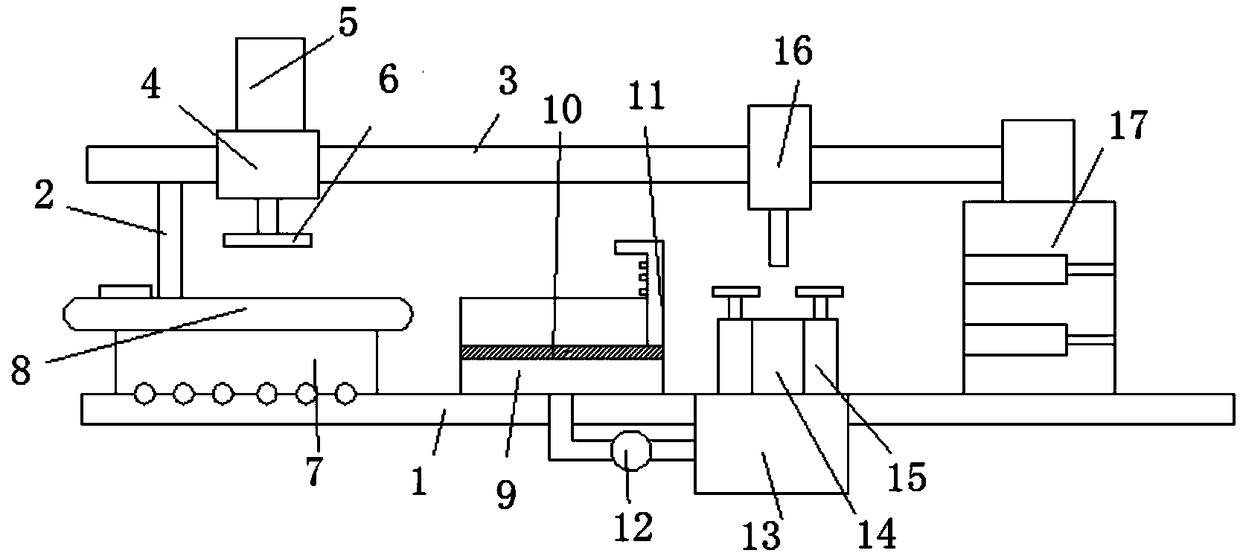

[0011] Referring to the accompanying drawings, a tool changing drilling device for CNC tool magazine machine tool production includes a base 1, a support column 2 is provided on the base 1, a beam plate 3 is provided on the top of the support center 2, and the beam plate The side wall of 3 is provided with sliding mobile seat 4, and the lower end of described mobile seat 4 is connected with grinding motor 5, and the end of described motor 5 is provided with grinding disc 6, and the below of described mobile seat 4 is provided with workpiece conveying table 7. The surface of the workpiece conveying platform 7 is provided with a workpiece conveyor belt 8, and one side of the workpiece conveying platform 7 is provided with a cleaning tank 9, and a filter screen 10 is arranged in the described cleaning tank 9, and the side of the cleaned tank 9 A drying pipe 11 is provided on the wall, and a water pump 12 is provided at the bottom of the cleaning tank 9 , and the water pump 12 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com