Laser-assisted atomization micro-arc oxidation device

A micro-arc oxidation and laser-assisted technology, which is applied in anodic oxidation and other directions, can solve the problem of low processing effect of small-area workpieces, and achieve the effects of improving effective energy utilization, uniform distribution, and overcoming potential differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

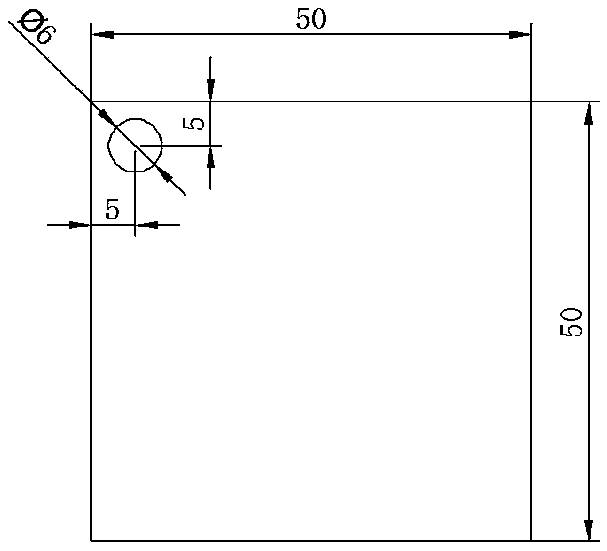

[0026] The workpiece 3 is aviation aluminum, and the specific shape is as follows figure 1 shown.

[0027] Workpiece 3 is processed as figure 1 As shown, a hole with a diameter of 6 mm is punched in the upper left corner of the workpiece 3 for connecting with the positive lead of the double pulse power supply 1 .

[0028] The treatment process of workpiece 3 is to grind it with 240#, 400#, and 800# sandpaper in sequence, then put it into acetone solution for two 10-min ultrasonic cleaning, and then use an ordinary hair dryer to dry it and pack it into a bag for later use.

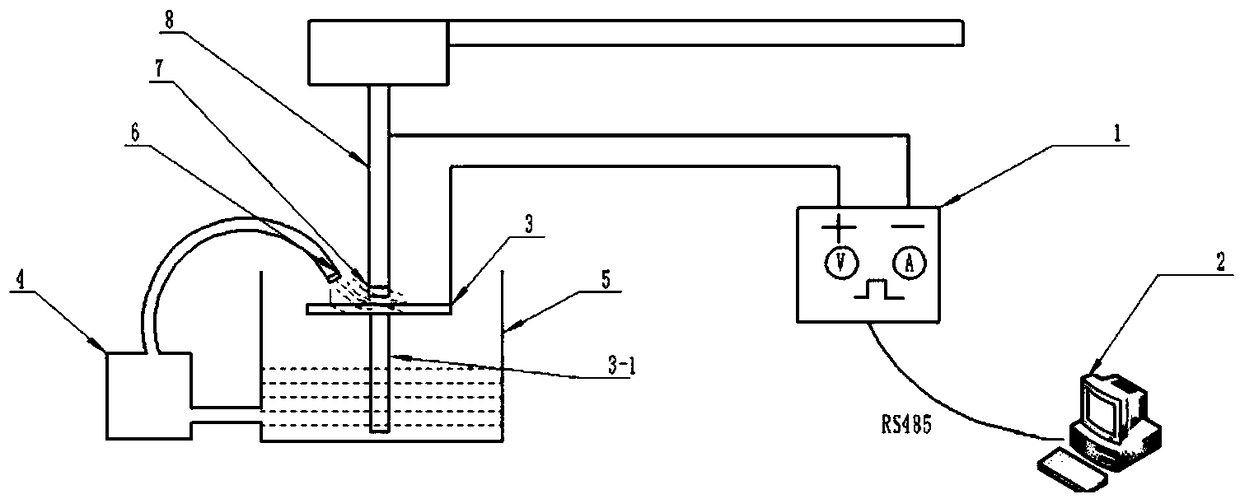

[0029] The parameters of the double pulse power supply 1 are set by the main control computer 2 through the RS485 protocol.

[0030] The surface morphology was observed with a TESCAN VEGA-XMU scanning electron microscope to observe the surface microscopic morphology of the ceramic film.

[0031] The thickness of the film layer is measured with an eddy current thickness gauge, and 8 points are taken for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com