Magnetic feeding type electrolysis electric spark combined machining method and device

A compound machining and EDM technology, applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of uncontrollable changes, affecting processing accuracy, and affecting control accuracy, so as to reduce friction and damping and improve control accuracy , Improve the effect of surface processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

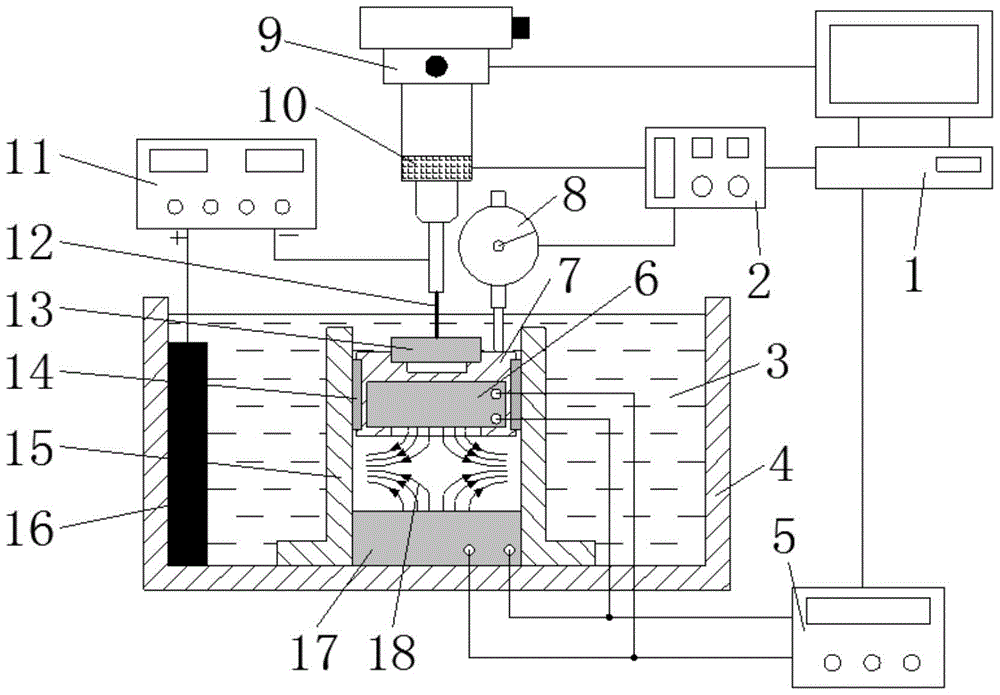

[0035] Such as figure 1 As shown, the magnetic-feed electrolytic EDM composite machining device of the present invention is used for processing insulating hard and brittle materials, including an electrolytic EDM system, a workpiece vertical movement system, a force feedback and a processing depth feedback adjustment system. The electrolytic spark machining system includes a machine tool 9, a working tank 4, an adjustable pulse power supply 11, a tool electrode, and an auxiliary electrode 16, the tool electrode is connected to the negative pole of the adjustable pulse power supply 11, and the auxiliary electrode 16 is connected to the negative pole of the adjustable pulse power supply 11. Adjustable pulse power supply 11 positive pole, alkaline solution 3 can be accommodat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com