Card paper storage mechanism and full-automatic packaging machine

A fully automatic packaging machine, cardboard technology, applied in the direction of transportation and packaging, packaging, transportation packaging, etc., can solve the problems of vacuum suction cup leakage, manipulator cannot pick up goods, etc., and achieve the effect of simple structure and high degree of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

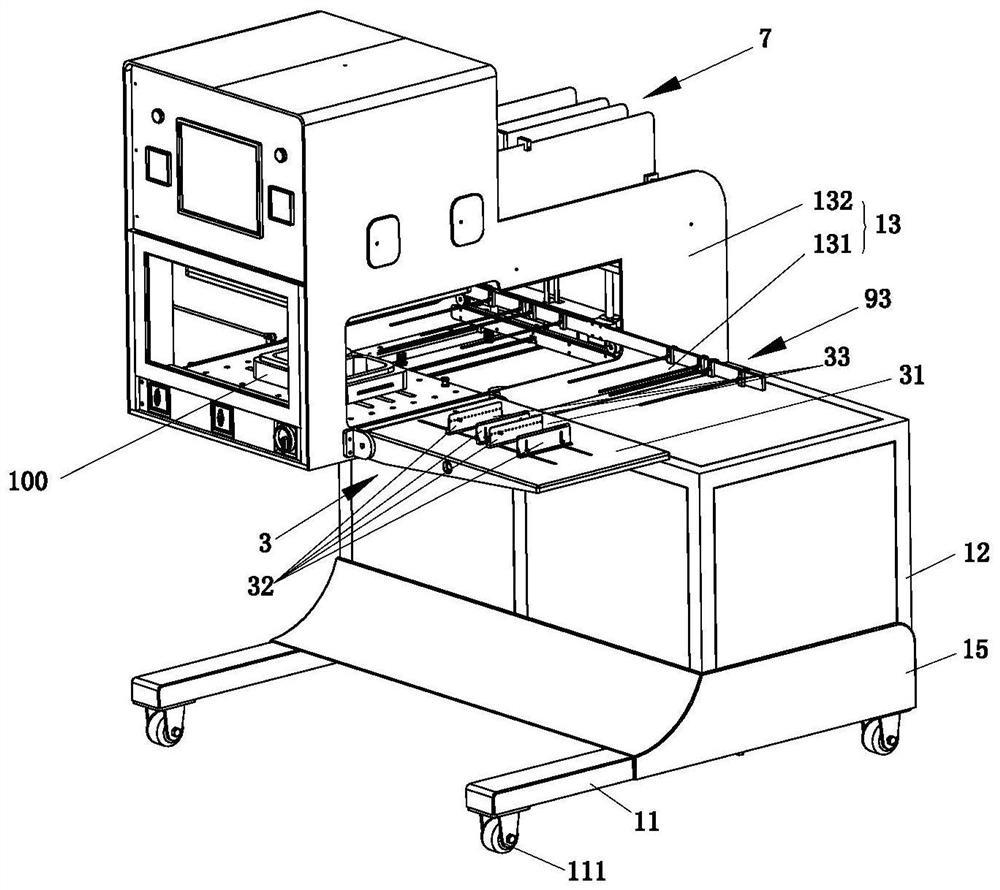

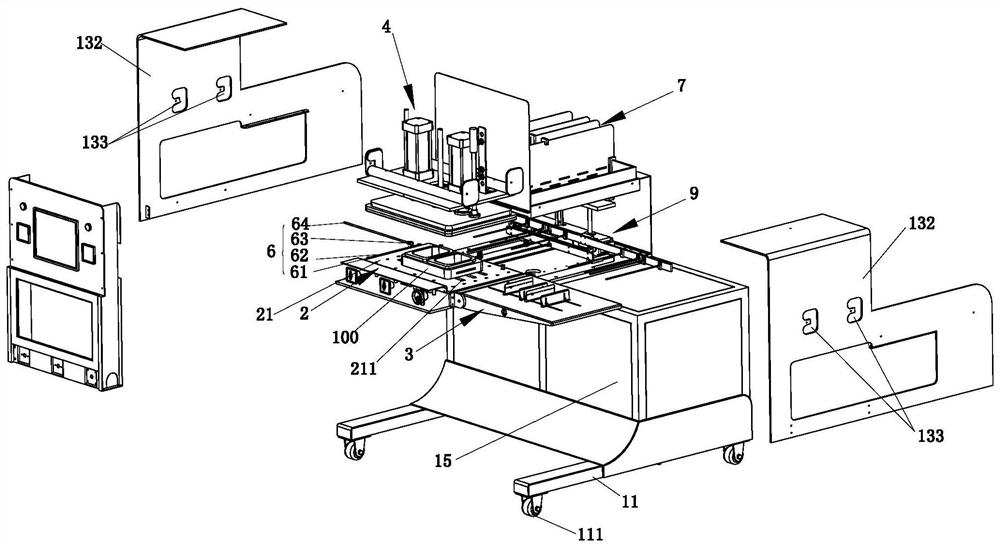

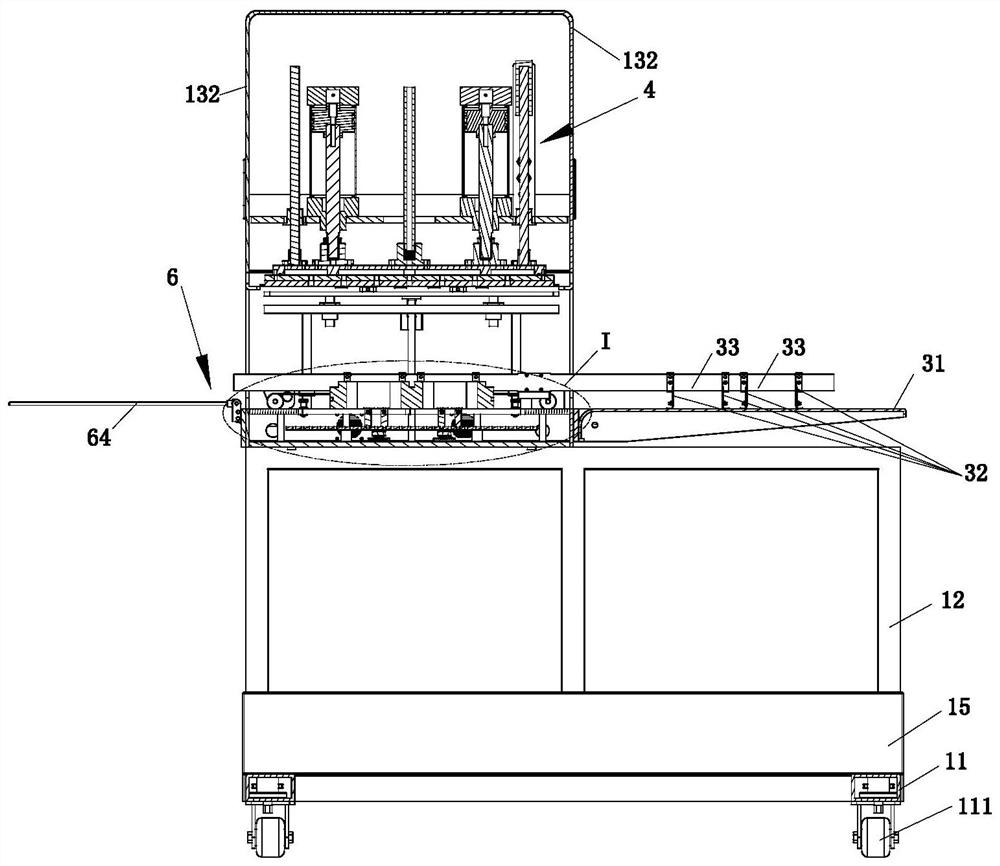

[0042] as attached figure 1 to attach Figure 5 Shown, a kind of full-automatic packaging machine comprises organic base frame 11 and is arranged on the cabinet body 12 on the frame frame 11; The bottom plate 131 is composed of side plates 132 arranged on opposite sides of the frame bottom plate 131 . Therefore, the whole automatic packaging machine forms a 匚-shaped body, which can be directly stuck on the production line when in use. In order to be suitable for assembly lines of different heights, a height adjustment device for adjusting the height of the chassis body 12 is provided between the base frame 11 and the chassis body 12 .

[0043] Specifically, as attached Figure 14 to attach Figure 18 As shown, the height adjustment device includes several adjustment assemblies, and each adjustment assembly includes a nut seat 141, a lifting screw 142, a sprocket 143, a lifting guide rod 144 and a lifting guide sleeve 145. More specifically, the nut seat 141 is There is a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap