Iron-based layered oxide positive electrode active material and preparation method and application thereof

A cathode active material and oxide technology, applied in the field of iron-based oxide cathode active material and its preparation, can solve the problems of reducing the electrical conductivity of the material, the battery rate performance, the influence of low temperature performance, etc., so as to improve the cycle life and ensure stability. , the effect of widening sodium ion channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

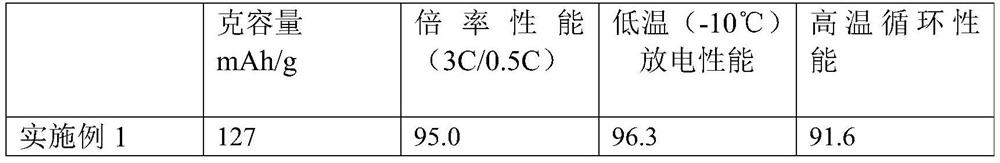

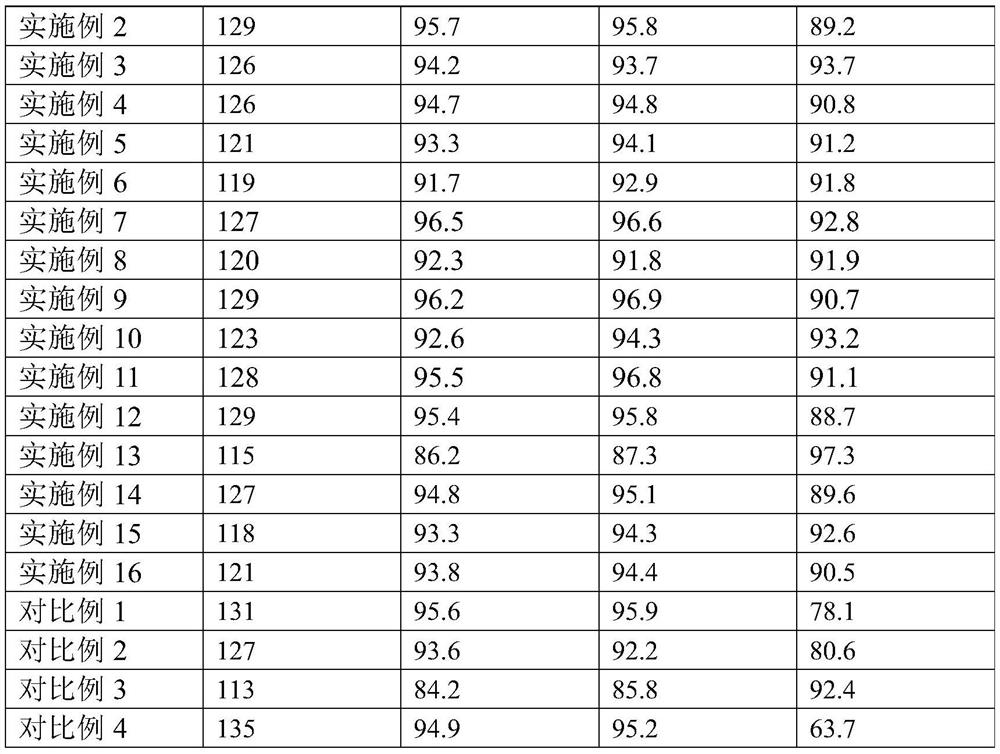

Examples

Embodiment 1

[0070] This embodiment provides an iron-based layered oxide cathode active material, which is prepared by the following method:

[0071] 1) Powdered (battery grade) FeSO 4 、NiSO 4 , MnSO 4 with Al 2 (SO 4 ) 3 , MgSO 4 Weigh according to a certain weight ratio, where FeSO 4 The addition amount makes the content of Fe element in the precursor be 55wt% of the total mass of the cation in the precursor, NiSO 4 The addition amount makes the content of Ni element in the precursor be 25wt% of the total mass of the cation in the precursor, MnSO 4 The addition amount makes the content of the Mn element in the precursor be 20wt% of the total mass of the cation in the precursor, Al 2 (SO 4 ) 3 The amount of addition makes the content of Al element in the precursor be 1500ppm (the ppm content here is based on the total mass of cations in the hydroxide precursor), MgSO 4 The addition amount makes the content of the Mg element in the precursor be 500ppm (the ppm content here is ba...

Embodiment 2

[0080] The difference between this embodiment and embodiment 1 is only that Al in step 1) is changed 2 (SO 4 ) 3 and MgSO 4 Add-on and step 5) Al 2 o 3 and the addition of MgO make the concentration of doping element Mg in the internal layer of the positive electrode active material be 200ppm (based on the quality of the inner layer), and the concentration of the doping element Al in the inner layer be 500ppm (based on the quality of the inner layer); The concentration of the doping element Mg in the outer layer of the active material is 600ppm (based on the quality of the outer layer), and the concentration of the doping element Al in the outer layer is 1800ppm (based on the quality of the outer layer);

[0081] The total concentration of the doping element Mg in the positive electrode material is 500ppm (based on the mass of the positive electrode active material), and the total concentration of the doping element Al in the positive electrode material is 1200ppm (based o...

Embodiment 3

[0083] The difference between this embodiment and embodiment 1 is only that Al in step 1) is changed 2 (SO 4 ) 3 and MgSO 4 Add-on and step 5) Al 2 o 3 and the addition of MgO make the concentration of the doping element Mg in the inner layer of the positive electrode active material be 300ppm (based on the inner layer quality), and the concentration of the doping element Al in the inner layer be 1000ppm (based on the inner layer quality), and the positive electrode The concentration of the doping element Mg in the outer layer of the active material is 1300ppm (based on the quality of the outer layer), and the concentration of the doping element Al in the outer layer is 4250ppm (based on the quality of the outer layer);

[0084] The total concentration of the doping element Mg in the positive electrode material is 1000ppm (based on the mass of the positive electrode active material), and the total concentration of the doping element Al in the positive electrode material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com