Non-supported catalytic ozonation sewage treatment system and method

A technology of ozone catalytic oxidation and sewage system, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, and water treatment of special compounds, etc. It can solve the problems of complicated preparation procedures of ozone catalysts, loss of catalytic activity of catalysts, and short service life of catalysts, etc. , to achieve the effects of improving ozone utilization efficiency, long life, and small project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

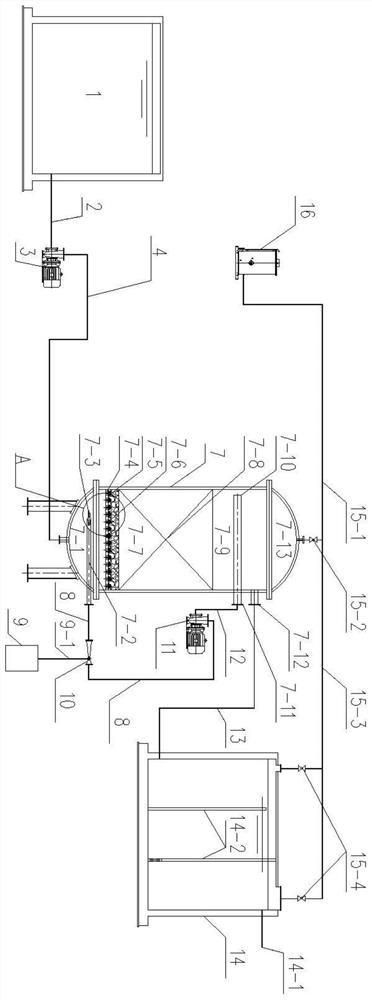

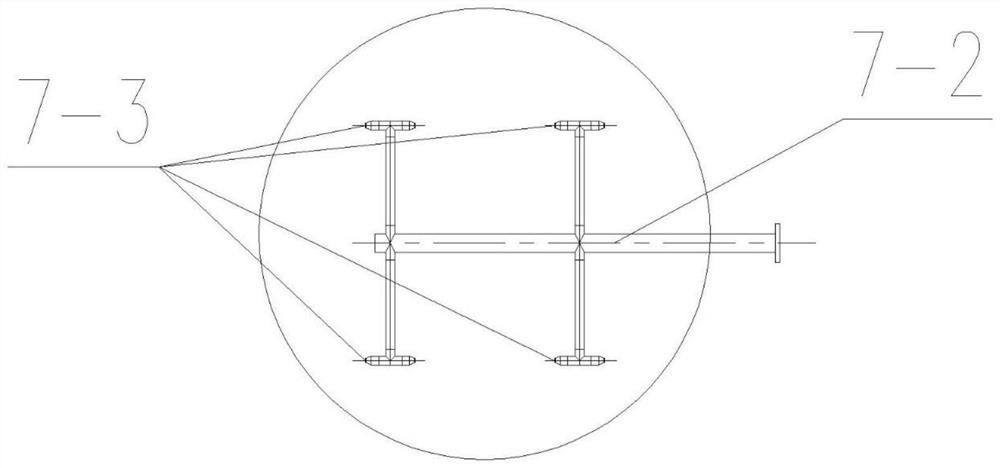

[0038] refer to figure 1 , 3 , 4, and 5, the present embodiment provides a non-loaded ozone catalytic oxidation treatment sewage system, including a water inlet unit 1, the water inlet unit 1 is connected to the bottom of the non-loaded ozone catalytic oxidation unit 7, and the non-loaded ozone catalytic oxidation unit 7 The top of the catalytic oxidation unit 7 is connected with an exhaust gas treatment unit 16, the upper part of the side wall of the non-loaded ozone catalytic oxidation unit 7 is connected with a water outlet unit 14, and the top of the water outlet unit 14 is connected with the tail gas treatment unit 16, and the side wall of the non-loaded ozone catalytic oxidation unit 7 A water outlet circulation unit is connected, the inlet end of the water outlet circulation unit communicates with the upper part of the side wall of the non-loaded ozone catalytic oxidation unit 7, the outlet end of the water outlet circulation unit communicates with the lower part of the...

Embodiment 2

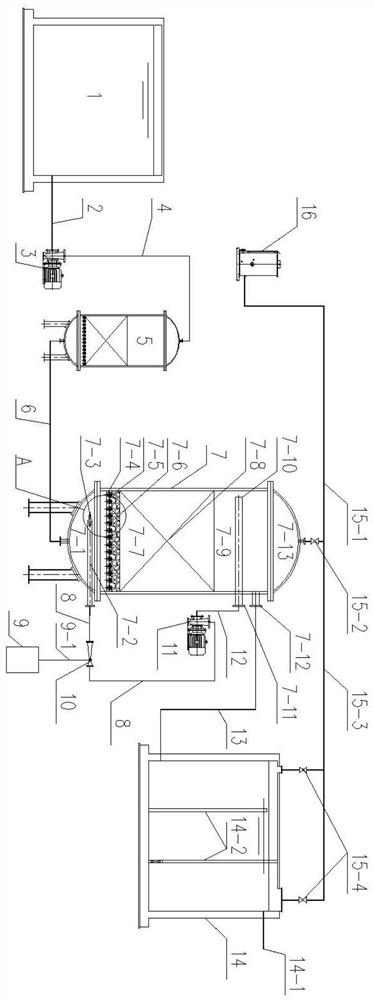

[0053] refer to figure 2 As shown, the difference between the sewage treatment system of this embodiment and Embodiment 1 is that the water in the water inlet pool of the water inlet unit 1 is obtained by sedimentation, and the water outlet end of the water inlet pump 3 is connected with a filter unit through the water inlet pump outlet pipe 4 5, the outlet end of the filter unit 5 communicates with the bottom of the non-load type ozone catalytic oxidation unit 7 water distribution and gas distribution area 7-1 through the filter unit outlet pipe 6, and the water inlet pump 3 pumps the sewage in the water inlet unit 1 into the To the filter unit 5, and then enter the non-supported ozone catalytic oxidation unit 7, by setting the filter unit 5 to remove the colloids and suspended solids that may be carried in the incoming water, so as to avoid the non-supported ozone catalytic oxidation unit 7 from clogging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com